Joining two ropes with a lashing for a rappel

|

|

Ben Zartman wrote: ….. Or you could continue to bluster. That's probably easier. Ben, I appreciate the technical discussion and I think both you and Kyle should avoid the personal snipes. edit - sorry to include you Kyle! |

|

|

Equalization? That's something that a phrenologist uses, yes? |

|

|

Terry E wrote: This thread is a classic version of "What do you think of my idea?" followed by a bunch of ad hominem attacks when people actually offer up thoughts that challenge the original poster. |

|

|

Terry E wrote: I’m not seeing any particularly personal snipes from Kyle. He’s making arguments using data and citing his sources. Let’s not make false equivalencies here. |

|

|

Ben Zartman wrote: It may just be my limited mental capacity, but it seems like most of the feedback you've solicited hasn't been that splices are untrustworthy. Rather there's a issues with the utility of those splices, the cost/benefit trade of something 2-4x similar products, quality control of your production and the reputation of a manufacturer frustrated and dismissive at the concerns of a market they're seeking to enter. Ben Zartman wrote: I'm at a loss for words at the suggestion an anchor doesn't need to survive when something goes catastrophically wrong. That's.... exactly when it needs to function. Losing a strand in an anchor to rockfall or gear failing is a very real occurrence. |

|

|

Terry E wrote: You're right. Please accept my apologies, everyone, and Kyle especially, for anything unpleasant I have said on this thread. Perhaps some of the snipes I was reacting to were the aggregate of this and other concurrent threads, where a good deal of sarcasm and pedantry was directed my way ("he misspelled 'rappel,' does he even know what it is?"). I'm introducing spliced rope technology into a relatively new use mode for it, so a certain amount of hesitation is to be expected. The limitations and cautions relating to the use of the materials are well-documented: I have secured UIAA-certification; been up-front about it, put safety labels on--I don't know what more I can do. And still, one claims that the UIAA must have screwed up; another that their testing is better, another that every anchor should reasonably be expected to survice a cataclysm--how do we even define such a catastrophic event, so that we can engineer for it? I can engineer spliced gear, with the materials available, to hold up to 110 tons, and anywhere in between. But climbing loads and anchor loads are relatively small. If equalizing is now regarded as impossible, then we need stronger cams, stoppers, etc. (Always on brand, I have hexes slung with 8,000lb bl spliced slings. ;), and we need better alternatives to the old-fashioned cordelette-style anchor with a BFK or girth-hitch master point. I personally don't object to the sliding X if confident in the placements, since it's stronger than a BFK, but maybe there's even a better way to equalize that we've yet realized (For swinging leads, I'm happy clove-hitching the lead line, which uses a minimum of gear, but that's for a different application). None of those things are a limitations of the gear, though, but of the technique. @Kyle: Marlow has not tested their rope with a BFK as it is used in making equalized anchors. You insist that they have. They haven't. This is not a personal attack. They simply haven't. Nor, AFIK, with a leg girth-hitched to a 'biner. I would strongly suggest, if a two-piece anchor is dodgy enough that one piece might reasonably pop, there need to be more pieces, or an adjustment of expectations. Lastly, for now, a poll: how many people have had one leg of an equalized anchor cut by rockfall? Does it happen once a year? Twice? There's a point at which catastrophic contingencies become so remote, they're not worth regarding. No amount of helmet will save your head from a rock as big as a TV. Does that mean the helmet is at fault, or that you're willing to climb even with that remote possiblity hanging (as it were) over your head, because it's so infrequent? The purpose of this very drifted thread was to see how folk would react to a minimal but scientifically engineered lashing to join two skinny-rope eyes. Apparently the climbing world isn't ready for that yet, and sees no value in it. That's fine, I didn't expect a chorus of huzzahs, and I appreciate the discussion. I think smaller, lighter gear is inevitably coming, and soon skinny fixing/rapping ropes will be more common than fat ones. But it might take longer than I thought. |

|

|

Ben Zartman wrote: They have tested a variety of very similar knots, and all of them reduce the strength by roughly the same amount. We can reasonably extrapolate that the results would also apply to a BHK. If you want to argue that a BHK is going to behave significantly differently than every other knot tested, the onus is on you to prove that.

Are you claiming a sliding-x is stronger than a BFK? How do you know that, if we don't have any information about BFK strength?

Go read that AAC article, or any up-to-date text on anchor building. We have clear limits on maximum forces in a factor 2 fall (12 kN UIAA rope test) and clear maximum strength of gear (normal sized cams and nuts are 10-12 kN minimum on the label, and often fail much higher in testing). We simply want our anchor connections to be at least the same strength. All other anchor constructions meet this criteria. Yours doesn't. I have already explained this several times in this discussion, and suggested reasonable minimum strength for each arm of an anchor.

The reason we build redundant anchors is for when the unexpected happens.

You're arguing that your product doesn't need to survive an accident, because accidents are rare? I don't really think there is much point in continuing. Like several other recent threads, you have posted a series of unsafe suggestions, and refused to consider alternative points of view. |

|

|

Ben, Can explain more completely and clearly the scenarios where this system of two skinny, static lines joined with your fixed eye/splice would be employed in climbing?

|

|

|

Ignoring the safety margin/strength issues for the moment- Ben- is this series of hitches in thin dyneema something you can tie at three in the morning, reliably, with frozen hands, racing to get off the mountain before a whiteout hits? I somehow don’t think so. I can tie a Gibbs, full or half, and a flat overhand with my eyes shut and half asleep, wearing thick gloves. |

|

|

If it's possible to develop a system that can easily join 1 spliced skinny (~6-7mm) to 1 unspliced lead (~9mm) line in a way that you can pull through a chain link in both directions, then that is a value proposition. The join mechanism has to be decently easy to implement - I'm not faffing around with a bunch of hitches and a little dyneema cord. I'm not going to carry 2 rap ropes in addition to a lead rope on a normal day out. I feel like a spliced lead rope introduces too many potential complications, none of which are completely unacceptable but probably are enough to outweigh the small conveniences provided by such a system. My main objections would be (1) I like having flexibility on which lead rope to use, there are many different brands, lengths, etc. (2) Tying into the spliced end as the leader seems annoying especially untying the knot later (3) Making sure the rope is always stacked so the unspliced side is for the leader adds faff (4) Having the leader always tie into the same end reduces rope lifespan (5) You can't cut the spliced side Your system has to make a substantive improvement on the typical 2 rope rappelling workflow without adding much if any overhead before this will see large scale adoption. |

|

|

Ben Zartman wrote: The foresight here is remarkable. https://sterlingrope.com/6-mm-trc/ https://sterlingrope.com/5-4-mm-v-tx-cord/ https://sterlingrope.com/5-9-mm-powercord/ https://www.petzl.com/US/en/Sport/Ropes/PUR-LINE-6-mm https://www.petzl.com/US/en/Sport/Ropes/RAD-LINE-6-mm https://www.bluewaterropes.com/product/titan-cord-with-hmpe-5mm/ https://www.mammut.com/us/en/products/2010-04070-11221/6-0-glacier-cord-dry |

|

|

@Kyle: I have suggested nothing unsafe: I advocate strongly for redundancy in anchors. But let's do some numbers: the 14mm Dyneema Yates Rabbit Runner is rated to 17kN. If tied into a knot, it's then weaker than the 12kN UIAA factor two fall you cited earlier. I would use it with no hesitation, because the contingency of unthinkable events stacking up to leave me with a factor 2 on one strand of an anchor is so remote that if I'm afraid of that, I may as well stay home. You should use my products responsibly, and use common sense and proper redundancy when building anchors with them. But you should also climb believing that if everythig goes so sideways that you're taking screamers onto a one-strand knotted anchor, it may have been your day to go. @Jonathan: busted. "a dozen" may have been hyperbolic. But you could tie your haulbag loop to the spliced loop of a haul line with a lashing. I use a lashing to secure my swami belt for climbing. You could use a multiple-pass lashing to get a precise length between a pin or bolt and a 'biner. A super-light ledge suspension could be made with them....I'm not saying everyone should climb with bits of dyneema in their pocket, but the uses for a lashing are limited only by the imagination (or lack thereof). @climbing weasel: It's very unlikely most people could make a secure lashing in a storm at 3 am with frozen fingers. But if you had read the thread, you'd know I've said the fiddliness is huge. This is an experimental use case for this sort of thing, and clearly it's not suitable for every situation. More of a "I wonder how light and low-profile I can make a connection between two eyes" with no other considerations that that. @szheng: It's impractical to splice lead ropes. The kernmantle construction doesn't lend itself to splicing. So the best way to use a spliced skinny rope with a fat rope is to pass an end of the fat rope through the eye and tie a bowline or a stopper knot in the fat rope, make sure the knot CAN'T pull through the rings, and use the skinny rope as a tagline to pull down the fat rope after rappelling. @Micah Hoover: See? everyone else is producing skinny ropes too. Dunno why my skinny rope ideas get so much hate. Betcha it won't be long before they jump on my bandwagon and start splicing eyes as well. |

|

|

Ben Zartman wrote: Can you post a link to the test data that supports this conclusion? I believe it’s incorrect, and the supporting data is in at least one of the sources I already cited in this thread. 17 kN isn't the ultimate strength of the material (it's the strength of the sewn eye), and this blended spectra/nylon doesn't lose nearly as much strength in a knot as pure dyneema. As a result, the knotted strength will be higher than you suggest. |

|

|

Climbing Weasel wrote: Why was this ignored? It’s the least faff way to make the spliced eye resemble a sensible choice.

|

|

|

Kyle Tarry wrote: Yates says their rabbit runner is Dyneema webbing. They have other slings that are blended Nylon/dyneema, but the only ingredient of the rabbit runner is listed as Dyneema. Using your method of suppositional engineering, where if one dyneema product behaves thus we can assume others do as well, my statement must be taken as correct. You haven't actually tested the Yates rabbit runner in the catastrophic failure mode you've finally had to appeal to as a hail-mary pass in your attempt to discredit a product you've never seen, used, or even imagined. I've submitted my product to testing by the UIAA in an ISO-9000 certified lab. I have labelled it accordingly, and if you'd ever seen as much as the packaging, you'd know that I recommend it not be knotted. It can survive a BFK in normal use (non-catastrophic-end-of-the-world scenario), but I recommend something different as best practice. It's one thing to spout numbers and unreliable data from uncalibrated-machine operators: it's another to use real engineering data and experience. I think, until we can test each specific product in each mode in question, in an actual test lab, we're not going to arrive at perfectly reliable numbers. All your test data so far seems to come from unaccredited labs. That's a red flag right there. Can you show me Hownot2's ISO certificate? Moyer's? et al's? Until you can, your engineering numbers are just a guess at best, and this devolves into a pissing match with no winner. @Jared E Climbing Weasel's post was not ignored: I addressed that idea upthread. It would absolutely work, but you'd have to sit there and pass 200 feet (or whatever the line length was) through the eye of the other one. I though the lashing was less faff, but yes, it'd work. |

|

|

Ben, Can you post a picture of what you mean by securing your swami belt with a lashing? I can’t visualize what that would look like. Thanks. |

|

|

^Don’t do it Ben! |

|

|

I always love when people actually read the Moyer et al paper, we actually have a QR code for it near our accessory cord cutting area, though I doubt strongly anyone has actually used it: Quad or triple length dyneema sling tied as a normal 3 piece anchor... perfect equalization doesn't happen between all 3 points, but usually, "good" equalization between 2 points does, especially if you pay attention to your loop lengths in a logical way... So thats 2 loops to a knot or 4 single strands to a knot... that is pretty acceptably strong per HowNot2's vids IIRC. Thats with a normal figure 8 or overhand to make the master point loop, BFK would be similar, likely ever so slightly higher strength. |

|

|

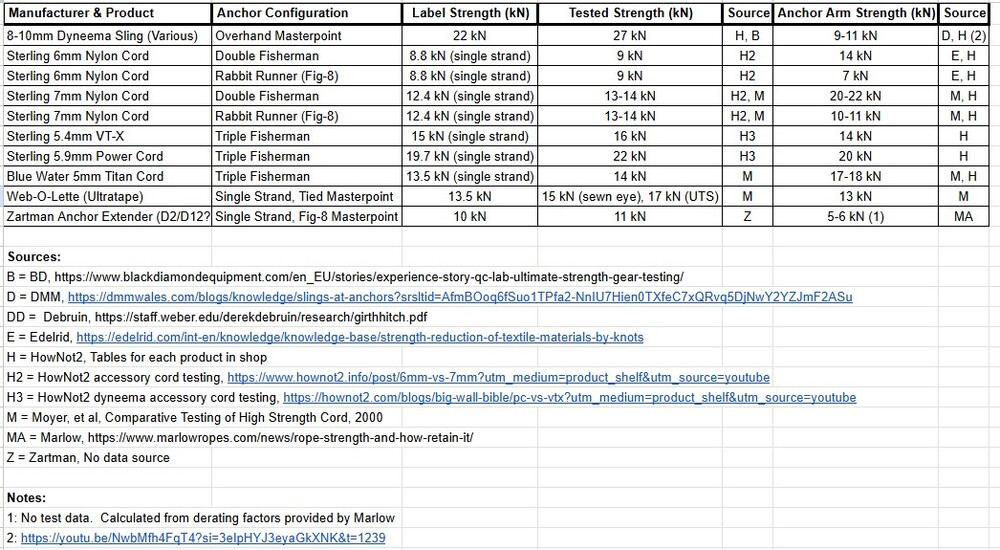

In the interest of doing something more productive than bickering with Ben, I put together a table with common anchor rigging configurations, and what strength we should expect from all of them. Sources are listed for each, and detailed at the bottom of the document. All numbers in this table come from the 3rd party sources listed, none of this is my data. This should be publicly available (read only) at this google docs link: https://docs.google.com/spreadsheets/d/1XfIbfyt08KjvdpXsjIPfoTxVmri1uIlj9aJMpXtgQ4w/edit?usp=sharing If you have additional data, corrections, other anchor configurations, etc., just shoot me a PM with your info or request and I am happy to edit, update, or correct this info. Note: I didn't include girth hitched dyneema slings in this table, because the failure mode of a single leg is often complex slipping behavior, as opposed to strength. That makes mapping it out quite difficult, relative to the other setups. See DeBruin, Camus, Siebert, HN2, and Edelrid for additional information on GH anchor failure dynamics. Hopefully this is useful for someone! Edit: Adding to this, common best practice is to build anchors such that a failure of 1 piece will not result in a system that fails under possible loads. This is tricky to put a finger on, but in general this implies that each individual leg of an anchor should be 8-12 kN strength. For justification of this, see the drop tests by DeBruin, comments by Moyer, and this AAC article on anchors: "Lesson Learned: Avoid building anchors where no single component isn't strong enough to hold any potential load the climbing team could create." "Lesson Learned: If you’re using self-adjusting systems, make sure ALL the components can survive the expected loads AND potential shock loads. Bomber pieces are required." Rigging an anchor out of a material whose strength drops below 8 kN once it is tied in a knot or a hitch would not meet these recommendations. |

|

|

Jonathan Barrett wrote: Not sure the pic posted. I can see it on my screen, but not when I update.... Ah, there it is, the picture of elegance and low-profile-ness. The Knotless Swami! |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook