Joining two ropes with a lashing for a rappel

|

|

Slim Pickenswrote: Ben, thanks for taking the time to make and post the video. I like your sweater very much. Having watched the video, I appreciated seeing the process in action. The thing that it comes down to for me is just that it's an incredibly impractical amount of faff compared to the time that it takes to tie a flat overhead bend. I can tie and dress two ropes together with a very simple knot in 2 seconds. I can do it from a hanging belay, I can do it by headlamp, I can do it when I'm totally shattered from a day's efforts, and my hands are shaky, and my eyes are bleary. For your system, instead of just tying a quick FOB, you're introducing this thin thread that then needs to be girthed to one rope, run multiple times through the other rope's eye, and then secured by a series of tiny hitches. I cannot imagine doing that when a storm is bearing down and I have to bail. I can't imagine doing that in the dark. I can tie a FOB with gloves on—can I construct this lashing with gloves on? No way. It's kind of neat, your system. I like these thin techy ropes, and the craft of splicing is cool. I've thought of wanting to learn to splice for customizing lanyards and stuff like that. And while a lot of this conversation has focused on people's doubts about the strength and safety of this system, I can't even get that far. The far greater complexity of this compared to just tying a simple knot makes something like this a total non-starter. |

|

|

Slim Pickenswrote: The macrame is definitely a bit silly, but it would be easy to replace with a soft shackle if there was any utility in carrying two statics with spliced eyes. |

|

|

Kyle Tarrywrote: You're now using "can" and "suggests" in place of real engineering. We won't know, until someone bothers to do comparative testing, how much a BFK will reduce the load-bearing of a single stand with an improperly equalized anchor. I recommend against the BFK specifically because of the propensity of Dyneema to lose strength in a tight knot. I expect it behaves differently in a BFK, since the turns are all more soft in that use. But again, I recommend girthing the masterpoint 'biner, which retains 80% of the strength. Still we won't know for sure until someone breaks a bunch of samples in a configuration not recommended by the manufacturer. Incidentally, in testing for the UIAA, the Anchor Extender broke at over 11kN. I put less than that on the rating tag to have a safety margin: you don't want people loading something close to break load without giving themselves a margin. Likewise my Seamless runners broke above 25kN, but I tagged them at 24. For the poster concerned with skinny ropes cutting: that's one of the virtues of that rope construction: Technora is very cut-resistant, and the Dyneema core even more so. So an edge that would slice a fat nylon rope would be less lethal to those materials, even in a thinner diameter. |

|

|

Slim Pickenswrote: I completely agree it's fiddly, and would be overmuch with frozen fingers. I wasn't thinking of ease of use or practicality here: I was thinking of lightest, lowest profile method. Every new thing, every process, every idea, starts somewhere, and often gets refined in a totally unexpected way. A diamond-knot soft shackle has been suggested--there's a refinement right there, one that sacrifices low-ness of profile for convenience. If spliced eyes ever become popular, do doubt something will evolve that's both strong, easy, and accepted by those who once doubted. But we gotta start somewhere, and I, for one, am glad for the discussion and feedback. |

|

|

Ben Zartmanwrote: The numbers come directly from break test data. Moyer is a good source on this, but HowNot2 has broken a bunch, Debruin (et al) also have. You have posted zero data, so I don't think this is a fair criticism.

That is not the case for girth hitching other dyneema products, so this would be an atypical result. The failure mode is often slippage, not breakage; this has also been tested by multiple sources and the data is in the public domain (HowNot2, Debruin, Delap, etc.)

Please support with data.

I provided this data and the source, for competing product (Web-O-Lette, see Moyer). For your product, we can either assume it will be similar to other dyneema slings, or you can provide the test data.

Responsible businesses don't just subtract 1 kN from the test data a call that a "safety margin." You need to conduct enough testing to statistically analyze the dataset, evaluate the distribution, and then use a standardized reduction from the mean (3 sigma is common in many industries, including climbing gear).

Sewn dyneema slings from Mammut test at 27+ kN. BD Dynex slings test at 27 kN. Both tag them at 22 kN. |

|

|

Repetitive sawing motion of dyneema on nylon sounds fun |

|

|

Ben Zartmanwrote: Since you already have eyes in the rope, why not just join them with one of those tiny keychain carabiners? Or maybe one of those velcro loops for tying up electrical cords? |

|

|

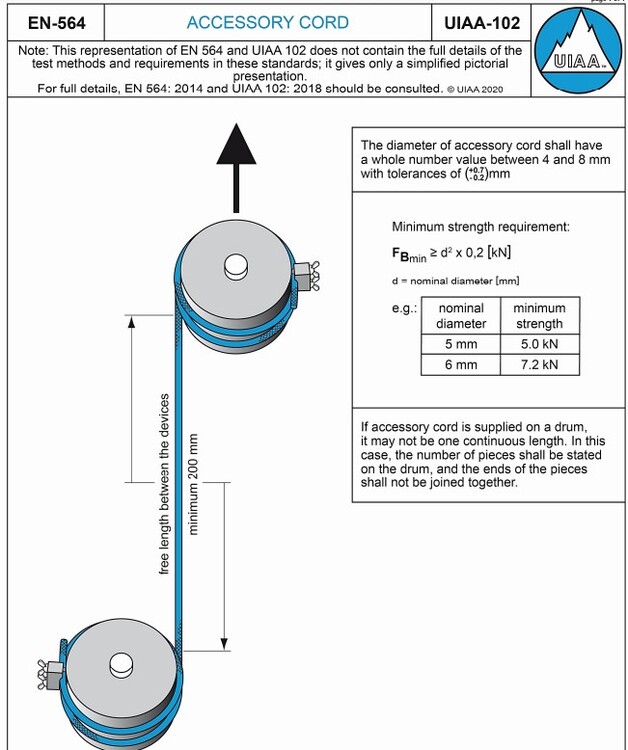

Ben, could you clarify what UIAA standard your 10kN anchor extender meets? Based on application, UIAA104/EN566 for slings would be most relevant, but that requires a 22kN MBS. Are you testing it to UIAA102/EN564 (accessory cord) instead? |

|

|

Andrew Ricewrote: Or even a quick link… |

|

|

@Eli W: the Anchor Extenders are certified to UIAA 102. The Seamless Runners and friction products are certified UIAA 104 @Andrew Rice: You'd need stronger Velcro. Perhaps there's a patent there for you. Or I could splice six-inch eyes and just keep on windin' that Velcro on..... @Kyle: I'm glad you're the judge of responsible business. Here I thought going through the UIAA certification process was responsible enough, but evidently there must be testing by Kyle-approved test labs. I have reams of test data published by the materials manufacturing company that inform me of the properties of the materials I use; I'm not the first or only person to make spliced rope or covered loops. It's a well-established technology, and all the engineering data I use, as well as the UIAA testing, is performed by ISO-9000 certified labs. Your guys may have hydraulic rams to break stuff, but their data is less valuable, since we can't know (without ISO) how or whether their machines are calibrated at all. But all that's aside. You're claiming slippage from a girth hitch, but you (or your fly-by-night shops') testing has been done on uncovered Dyneema slings. A covered Dyneema rope might behave far differently--you'll never know till you actually test, rather than guess. I'm perfectly comfortable recommending a girth hitch because the contingeny of a strand breaking is so impossibly remote without something REALLY stupid being done, that it's like super gluing your pants onto the belt and suspenders. Anything can be pulled on or used wrongly and made to fail, and no one can manufacture something idiot-proof enough for someone not to be able to damage it, so we can only manufacture for a certain range of uses, and hope people will behave responsibly. But I'm beginning to suspect that all this pushback from you comes from a deeper well--no longer merely a discourse on a different sort of gear, I detect an umbrageous undertone. Have I injured you in some way? Do my irrefutable claims of my gear's betterness cause you some personal insecurity or restlessness? What dog do you have in this fight that a new idea threatens you? You're not being forced to buy or use my gear. I'm not being cagey about its construction, use, or certifications. Do self-esteem issues require you to feel like you've won some battle? Let's talk about those for a bit, and maybe you'll feel better. I'm here to listen. |

|

|

This whole two rope idea is silly for climbing-- but I do think his seamless quickdraw design would be great for alpine climbing-- as light (lighter) than an alpine runner, adjustable to two lengths, but with the security of a standard quickdraw (ideally the loop would be a bit tighter to hold the biner better) |

|

|

Ben Zartmanwrote: In that case, issuing the certificate seems like an oversight on the UIAA‘s part, given that you are marketing the product as an anchor I don’t think anyone would advise a 5mm nylon cordelette, but that is equivalent in strength to your offering for the outside legs of the anchor even before accounting for the different knot losses of nylon vs UHMWPE (2 strands of 5kn vs 1 strand of 10kn). |

|

|

Ben Wah, Benhamein, Young Ben,I watched your video! So good to see you old friend, didn't really expect to see you when I clicked on the thread, but was tickled nonetheless. I unfortunately have nothing to add about the subject but wanted to say howdy. :) Carry on! |

|

|

@heyzeus: Amigo! shoot me an email and let's catch up. It's a long time since Hollywood. @MP: thanks for the advice. I'm drifting in those very directions; it's just super time-consuming to set up websites and webstores, especially when I have to have someone to do it for me, since I don't code. Everything is where it currently is as an expedient of necessity, but the plan is to separate the luxury climbing brand, Legendary Climbing Gear, from the sailing brand of Zartman Rigging. I'm a one-man show right now, with help from my computer-savvy wife who doesn't have all day to dedicate to web design. As this gathers steam, I'll definitely move in the directions you've suggested. @Eli W: you can question the UIAA about it if you like, but we tested the pieces to their 102 standard with the spliced eye included in the testing. So the piece, with eyes spliced in, meets UIAA 102. I guess when the doubters start questioning the certification agency, it's because they're run out of ammo. Your quibble about the name is foolish: it's a name, like "rabbit runner," which contains no varmints. I needed a brand name for a specialty accessory cord offering. It bridges the gap between the anchor placements and the masterpoint. It....extends from rock to 'biner. It has a conservatively rated UIAA label. I can't think what more you want. |

|

|

Ben Zartmanwrote: UIAA 102 is a generic test for accessory cord, it doesn't mean something is strong enough to be an anchor. 4mm nylon cords with a 3.2 kN strength rating will also pass UIAA 102; nobody would say they are ok to use as an anchor.

I didn't make up any of the quality measures I mentioned, they are all standard practices across industries where safety is important. There is information about them in a climbing context on the DMM page that I already posted earlier in this thread. Here's similar info from Sterling. There are a bunch of other standard things companies do in addition to this, to make sure product going out the door is safe for people who depend on it. |

|

|

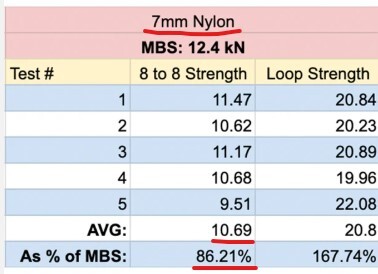

Eli Wwrote: I agree that 5mm nylon is too skinny for cordelette. However, there are plenty of people who use 7mm for "snake cord" which I imagine is in the same ballpark as this stuff (or even slightly weaker), given the full strength eyes. |

|

|

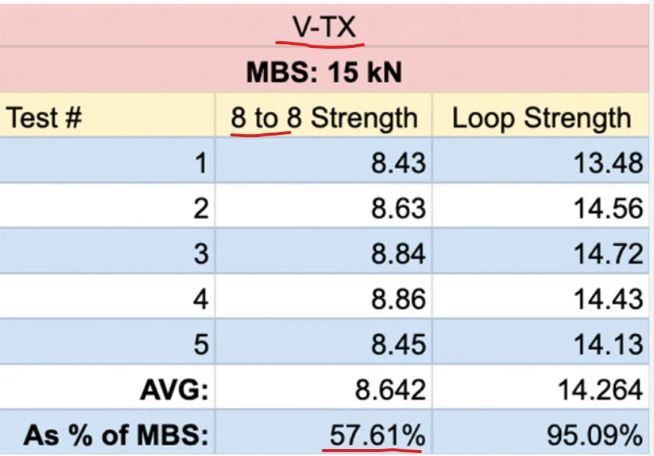

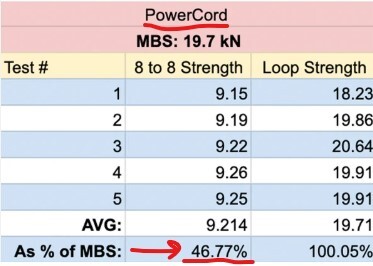

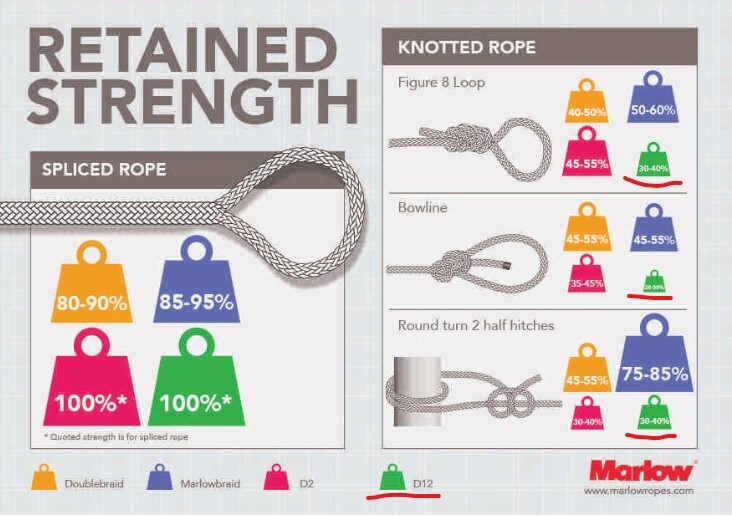

mbkwrote: Not once you tie a masterpoint knot or hitch in it, because nylon loses minimal strength in a knot but dyneema loses a lot. 7mm nylon accessory cord, rated at ~12 kN, still holds ~11 kN with a fig-8 knot in it (Moyer, HN2). However, dyneema products (with sheaths) like VT-X, Powercord, and Titan cord, all hold ~50% of their rated strength once you tie a knot (Moyer, HN2). So, in an anchor with a typical masterpoint knot, the 7 mm cord is still going to hold 10+ kN per leg, but a dyneema product that breaks at 10 kN without a knot is only going to hold 4-6 kN per leg with the knot. OP repeatedly claims that their product doesn't follow the strength reduction trend of every other dyneema product on the market, but note that Marlow (manufacturer of similar products for splicing) says "Ropes made from HMPE or LCP type material (for example Dyneema or Vectran) should be assumed to retain only 40 percent of their strength when knotted". |

|

|

mbkwrote: The full strength eyes don’t matter, the weak point is the 10Kn single strand going into the BFK with this product vs two 7mm (10kN x 2)strands with traditional cordelette or a single 22kN strand with rabbit runner style anchor slings that are actually rated as slings.

|

|

|

Kyle Tarrywrote: You misunderstand the way anchors are built. If you took a single strand of my Anchor Extender and tied a knot in the end instead of the splice, it would indeed lose a great deal of strength. That is why there's a spliced eye, which per the Marlow chart (my rope is D2 from Marlow, incidentally), retains 100% of published strength. If you have two equalized legs, then even with a BFK or girth hitch, you'd have to exceed 80% of the single-strand break load of 10+kN, because you have two legs sharing the load. With a 3-piece anchor, you'd have to get even more rowdy. By the time you achieve that sort of load, you're exceeding the ratings of much of the pro: stoppers, cams, hexes, etc used to build your anchor. And if a knot wigs you out, and you know the pieces are bomber, you need not tie a knot at all: just clip the bight, and you're lost no strength at all. Notice that the different knots, because they put a different bend radius on the line, weaken it differently. Since you're the one worried about it, you could test this specific rope with a BFK. Or you could continue to bluster. That's probably easier. Funny, some time ago when I asked a guide about the strength reduction of a BFK in a Dyneema sling, his answer was the same: with so many parts to the system, it would take a cataclysm to make it fail. If spliced gear gives you the heeby-jeebies, then I urge you to avoid it. Those who have the mental capacity to read the rating tag, understand the engineering of anchors and the limitations of gear, will take these for what they are: a spliced piece of Dyneema cord that breaks at 10+ kN in single strand. Would I build a wall anchor with it in single strand? Of course not--but I'd use it to engage some remote piece of gear as part of my equalized system. I can wrap trees with it, and have two legs, or four, sharing the load. Anchor building requires a bit of skill and common sense. I recommend you learn how to do it sometime. |

|

|

Ben Zartmanwrote: Load sharing doesn't work this reliably, especially with a fixed master point. See Long/Gaines and many others. https://americanalpineclub.org/news/2017/7/31/anchors "Anchors never really equalize. That is to say, they never manage to equally distribute the total load of the climbing team equally to all the components in the anchor, unless there is only one component. Yet, much false confidence and unnecessary time is contributed to achieving the elusive goal of equalization...As a result, anchors that funnel into a masterpoint do not succeed, as intended, in aggregating the strength of the things they are attached to. A strong anchor thus is only as strong as the component that is holding most of the weight most of the time." "However, since equalization never really occurs, one of those pieces will be holding most of the weight most of the time. In that case, a single load that exceeds 6kN could sequentially rip every piece out of the rock, resulting in a catastrophic failure." "Equalization" was a popular topic a few decades ago, before testing determined it wasn't as effective as believed, and anchor best practices were updated accordingly. An important property of an equalized anchor is to protect you from failure of a piece. If the load all goes onto one strand, you want it to be at least as strong as that piece, not ~5 kN.

The manufacturer, Marlow, already did, and I already posted it in the thread. 30-50% strength, consistently for a variety of knots. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook