|

|

Jim Day

·

Jan 23, 2025

·

Fort Worth, TX

· Joined Jan 2020

· Points: 3,159

·

Jan 23, 2025

·

Fort Worth, TX

· Joined Jan 2020

· Points: 3,159

Thank you Kevin for your thoughtful and thorough testing. I really appreciate the level of consideration you take! Did you happen to notice if there's a difference between 12mmx12mm vs 12mmx10mm bolt/hanger combinations, in regards to when they will start to spin/ become spinners after relatively low forces/ repeated forces (like 1-3 kn?) I've been checking regularly if longer options appear on hownot2, especially if 1/2" x 120mm 304s becomes an option!

|

|

|

Matt King

·

Jan 25, 2025

·

Durango, CO

· Joined Oct 2009

· Points: 532

J Wwrote:Regarding hangers, the Powers 1/2” 5-piece sleeve bolt fits into a 3/8” hanger. Is that also the case for these CT sleeves? The inner bolt minus the sleeve of the 12mm CT sleeve bolt slides through the 3/8' hole of a FIXE hanger.

|

|

|

Adam W

·

Feb 26, 2025

·

TX/Nevada

· Joined Dec 2019

· Points: 532

Question if anyone from Climbing Taiwan/Hownot2 looks through here. Is it possible to make these sleeve bolts with a matte black finish/coating on the bolt head..probably for a little extra cost? I use matte black nuts on wedge bolts with a coat or two of whatever color the hanger is painted and when the paint chips it goes back to the underlying black rather than shiny stainless, example below

|

|

|

Kevin Maliczak

·

Feb 27, 2025

·

Living in Taiwan. From Sout…

· Joined Apr 2018

· Points: 345

Adam Wwrote:Question if anyone from Climbing Taiwan/Hownot2 looks through here. Is it possible to make these sleeve bolts with a matte black finish/coating on the bolt head..probably for a little extra cost? I use matte black nuts on wedge bolts with a coat or two of whatever color the hanger is painted and when the paint chips it goes back to the underlying black rather than shiny stainless, example below Hi Adam, Kevin here from Climbing Taiwan. We could buy hex nuts (for our wedge bolts) and hex bolts (for our sleeve bolts) of the same grade stainless steel that are already black from the manufacturer. I'll look more in to it to see what the cost difference is. Alternatively, we were looking at getting into powder-coating. It has more versatility in terms of color choice and opens up the opportunity to do custom requests. It'll take a few months until we can get this going though. We also got requests for colored hangers. Lappas is already working powder-coated hangers for How NOT 2, and can already beat out our price of 304 SS hangers (because they make em' manufacturer direct) whereas we still order from a factory.

|

|

|

Kevin Maliczak

·

Feb 27, 2025

·

Living in Taiwan. From Sout…

· Joined Apr 2018

· Points: 345

Jim Daywrote:Thank you Kevin for your thoughtful and thorough testing. I really appreciate the level of consideration you take! Did you happen to notice if there's a difference between 12mmx12mm vs 12mmx10mm bolt/hanger combinations, in regards to when they will start to spin/ become spinners after relatively low forces/ repeated forces (like 1-3 kn?) I've been checking regularly if longer options appear on hownot2, especially if 1/2" x 120mm 304s becomes an option! Hi Jim, We got some bolt testing scheduled. I'll add this in. Thanks for the great question!

|

|

|

Josh Janes

·

Feb 27, 2025

·

Unknown Hometown

· Joined Jun 2001

· Points: 10,294

·

Feb 27, 2025

·

Unknown Hometown

· Joined Jun 2001

· Points: 10,294

I am stoked on the possibility of powder coating!

|

|

|

Adam W

·

Feb 27, 2025

·

TX/Nevada

· Joined Dec 2019

· Points: 532

Kevin Maliczakwrote: Hi Adam, Kevin here from Climbing Taiwan. We could buy hex nuts (for our wedge bolts) and hex bolts (for our sleeve bolts) of the same grade stainless steel that are already black from the manufacturer. I'll look more in to it to see what the cost difference is. Alternatively, we were looking at getting into powder-coating. It has more versatility in terms of color choice and opens up the opportunity to do custom requests. It'll take a few months until we can get this going though. We also got requests for colored hangers. Lappas is already working powder-coated hangers for How NOT 2, and can already beat out our price of 304 SS hangers (because they make em' manufacturer direct) whereas we still order from a factory. Thanks, I would be interested in hearing the cost difference of powder coated or black nuts for wedge bolts. The M10 A4/black nuts cost me around .37 cents last order from Accu. I was wondering about the head on the sleeve bolts though specifically since I can’t really paint them prior to installation since hammer hits will just knock off the paint.

|

|

|

Kevin Maliczak

·

Mar 2, 2025

·

Living in Taiwan. From Sout…

· Joined Apr 2018

· Points: 345

Jim Daywrote:Thank you Kevin for your thoughtful and thorough testing. I really appreciate the level of consideration you take! Did you happen to notice if there's a difference between 12mmx12mm vs 12mmx10mm bolt/hanger combinations, in regards to when they will start to spin/ become spinners after relatively low forces/ repeated forces (like 1-3 kn?) I've been checking regularly if longer options appear on hownot2, especially if 1/2" x 120mm 304s becomes an option! Hi Jim, Did some testing over the weekend in a sandstone that's less than half the compressive strength (according to our rebound hammer basic results) of the far harder quartz sandstone we primarily test in. After the load, we release it then yank at they connector to see if there's any movement of the hanger. Here's our data so far (that we'll update as we go along): - CTW 10mm x 70mm sleeve bolt with either an 8mm or 10mm hole hanger in SHEAR: at 8 kN the hanger will be slightly loose...still need to test more variables.

- CTW 10mm x 70mm sleeve bolt with either an 8mm or 10mm hole hanger in TENSION: 1 kN no movement, 2 kN no movement, 3 kN the hanger will be slightly loose

- CTW 12mm x 80mm sleeve bolt with a 10mm hole hanger in SHEAR: No movement at all incrementally to 8 kN. And then 8 kN 10x, still no movement of the hanger. (This is our recommended combo for all climbing routes).

- CTW 12mm x 80mm sleeve bolt with a 10mm hole hanger in TENSION: pending

- CTW 12mm x 80mm sleeve bolt with a 1/2" hole hanger in SHEAR: 2 kN no movement, 3 kN little movement. Then re-torqued to 40 N.m.(30 ftlb) and loaded to 5kN and no movement. Then 8kN little movement. (What's happening here is the hanger is initially crushing the sleeve to butt up against the hex bolt (in order to close up the small gap). So this configuration might have to get re-torqued after loading.

- CTW 12mm x 80mm sleeve bolt with a 1/2" hole hanger in TENSION: We first pulled to 8kN, some movement of hanger. Then re-torqued to the lower recc. of 33Nm(25 ftlb), then pulled to 3 kN, not loose, then 5kN not loose. This configuration might also have to get re-torqued after loading.

We also tested a couple 12mm x 120mm long sleeve bolts in the same sandstone. In our previous tests, the 80mm long ones will all pull out of the rock up to 40kN in tension. And in shear pulled out at high 40's. For the 120mm long ones, we got 50kN in shear where the hanger broke, (stronger hanger I'm sure the bolt would have broken). And in tension the head head snapped off at 55kN. So these longer ones are definitely promising for medium/softer rock. How NOT 2 should have the 120mm long ones in both 10mm and 12mm hopefully by the end of the month. We're in the middle of adjusting our 1/2" size sleeve bolts for a tighter fit, so they wont be available for awhile.

|

|

|

Jim Day

·

Mar 2, 2025

·

Fort Worth, TX

· Joined Jan 2020

· Points: 3,159

·

Mar 2, 2025

·

Fort Worth, TX

· Joined Jan 2020

· Points: 3,159

Kevin Maliczakwrote: Hi Jim, Did some testing over the weekend in a sandstone that's less than half the compressive strength (according to our rebound hammer basic results) of the far harder quartz sandstone we primarily test in. After the load, we release it then yank at they connector to see if there's any movement of the hanger. Here's our data so far (that we'll update as we go along): - CTW 12mm x 80mm sleeve bolt with a 1/2" hole hanger in SHEAR: No movement at all incrementally to 8 kN. And then 8 kN 10x, still no movement of the hanger. (This is our recommended combo for all climbing routes).

Thank you for the update, Kevin! That is impressive and very promising performance. Did you also do this test with 12mm sleeve bolt with a 3/8ths or 10mm hanger in SHEAR (i.e. hanger over the bolt shaft, not the sleeve)? I ordered a couple 1/2" x 80mm which arrived a couple of weeks ago, I'm looking forward to using them. Also cant wait for 120mm length!

|

|

|

Kevin Maliczak

·

Mar 2, 2025

·

Living in Taiwan. From Sout…

· Joined Apr 2018

· Points: 345

Jim Daywrote: Did you also do this test with 12mm sleeve bolt with a 3/8ths or 10mm hanger in SHEAR (i.e. hanger over the bolt shaft, not the sleeve)? Woops copy/paste typo. (Updated my original post) Yes, we did the 12mm sleeve bolt with a 10mm hanger. That's our recommended combo.

|

|

|

Brandon Adams

·

Mar 2, 2025

·

Unknown Hometown

· Joined Oct 2010

· Points: 3,937

Anyone place some of these in super soft rock (of the soft Zion sandstone variety per se)? I've had great luck with Cobra supersleeve anchors tightening down appropriately, but Powers 5 piece and the older Rawls sometimes produce spinners. The Cobras are expensive and hard to find. Thoughts? Also... yeah yeah yeah, glue ins, yadda yadda. Im thinking of for ground up bolting options.

|

|

|

KrisG

·

Mar 3, 2025

·

Red Rock, NV

· Joined Mar 2012

· Points: 3,245

Brandon Adamswrote:Anyone place some of these in super soft rock (of the soft Zion sandstone variety per se)? I've had great luck with Cobra supersleeve anchors tightening down appropriately, but Powers 5 piece and the older Rawls sometimes produce spinners. The Cobras are expensive and hard to find. Thoughts? Also... yeah yeah yeah, glue ins, yadda yadda. Im thinking of for ground up bolting options. I bolted a sport route with them in Red Rock Canyon (same aztec/navajo sandstone). They installed very much like 5-piece in my experience. A straight hole with a fresh bit and they go in easy, anything else and they require more effort/hammering. I'll go back after a few more months (or sooner if the route receives noticeable traffic) and check them for spinners. I know you said ground-up application (respect), but the PITA of dealing with spinners and loosening bolts over time is one of the main reasons I switched to glue-ins years ago for aztec/navajo sandstone. This is certainly true for sport crag type routes that may see a lot of traffic/falls, and bolts protecting traverses.

|

|

|

Josh Janes

·

Mar 3, 2025

·

Unknown Hometown

· Joined Jun 2001

· Points: 10,294

·

Mar 3, 2025

·

Unknown Hometown

· Joined Jun 2001

· Points: 10,294

Kris, what route exactly? 10, 12mm, or 1/2"? I'd love to go check it (meaning these bolts in RR sandstone) out in person.

|

|

|

KrisG

·

Mar 3, 2025

·

Red Rock, NV

· Joined Mar 2012

· Points: 3,245

Josh Janeswrote:Kris, what route exactly? 10, 12mm, or 1/2"? I'd love to go check it (meaning these bolts in RR sandstone) out in person. Magical Starborn Princess at Great Red Book Area. Only the first pitch has them. There's a mixture of bolts types on that route, I think they are on the upper half. 12mm with Lappas Desert Tortoise hangers.

|

|

|

Tal M

·

May 5, 2025

·

Denver, CO

· Joined Dec 2018

· Points: 5,098

Wanted to reach out here because I’m not sure if it’s user error or not, but I haven’t been stoked with these so far. My set up is the 12mm sleeve bolts with 10mm petzl hangers (washer between the hex head and outside of the hanger) - How do I avoid having the hanger spin with the bolt while tightening them down? This has been an issue with the majority of them I’ve installed

- Loosened one after installing to replace the hanger and was unable to re-tighten down. I tried pulling out on the hanger while tightening down but that didn’t seem to work either. I’ll try and get a tuning fork to get better leverage in the future, but is this common? Is there a way to avoid this?

|

|

|

Josh Janes

·

May 5, 2025

·

Unknown Hometown

· Joined Jun 2001

· Points: 10,294

·

May 5, 2025

·

Unknown Hometown

· Joined Jun 2001

· Points: 10,294

Tal Mwrote:Wanted to reach out here because I’m not sure if it’s user error or not, but I haven’t been stoked with these so far. My set up is the 12mm sleeve bolts with 10mm petzl hangers (washer between the hex head and outside of the hanger) - How do I avoid having the hanger spin with the bolt while tightening them down? This has been an issue with the majority of them I’ve installed

- Loosened one after installing to replace the hanger and was unable to re-tighten down. I tried pulling out on the hanger while tightening down but that didn’t seem to work either. I’ll try and get a tuning fork to get better leverage in the future, but is this common? Is there a way to avoid this?

- Use hangers with anti-spin dimples (eg. Fixe or CT Sandstorm/Tsunami). This can be frustrating for sure but I definitely find it to be more of a function of the particular hanger and rock surface interface than the bolt being used.

- I've only had this happen a couple times with Powers 5-piece bolts (out of hundreds installed), but it is the worst. I'm not always sure why but my suspicion is I didn't clean the hole well enough. It would be a serious bummer if these new CT sleeve bolts were more prone to this. Sometimes you can create that extra bit of grab you need by (gently) funking the bolt outwards to try to re-seat the cone into the sleeve.

These two issues you've raised are a bummer for sure but hopefully it is not indicative of this bolt being a bad design. Curious what rock you're installing them in?

|

|

|

Tal M

·

May 5, 2025

·

Denver, CO

· Joined Dec 2018

· Points: 5,098

Josh Janeswrote: - Use hangers with anti-spin dimples (eg. Fixe or CT Sandstorm/Tsunami). This can be frustrating for sure but I definitely find it to be more of a function of the particular hanger and rock surface interface than the bolt being used.

- I've only had this happen a couple times with Powers 5-piece bolts (out of hundreds installed), but it is the worst. I'm not always sure why but my suspicion is I didn't clean the hole well enough. It would be a serious bummer if these new CT sleeve bolts were more prone to this. Sometimes you can create that extra bit of grab you need by (gently) funking the bolt outwards to try to re-seat the cone into the sleeve.

These two issues you've raised are a bummer for sure but hopefully it is not indicative of this bolt being a bad design. Curious what rock you're installing them in? The Petzl hangers have the anti-spin dimples. I’m mostly installing on granite or granite-like rock (granitic gneiss). I tried funking it to no avail but in reality I may just move and patch the hole to a different spot anyways - still frustrating. I cleaned the hole pretty well (multiple brushings and blowing with the CT mini blower) Another person I was out with had an issue with a bolt not installing all of the way, getting stuck about 3/4 of the way in. I’ve seen that happen with standard 5-piece as well, but combined with the spinning hangers and now this other issue, my overall impression is fairly negative

|

|

|

nbrown

·

May 5, 2025

·

Unknown Hometown

· Joined Nov 2007

· Points: 8,101

Tal Mwrote: The Petzl hangers have the anti-spin dimples. I’m mostly installing on granite or granite-like rock (granitic gneiss). I tried funking it to no avail but in reality I may just move and patch the hole to a different spot anyways - still frustrating. I cleaned the hole pretty well (multiple brushings and blowing with the CT mini blower) Another person I was out with had an issue with a bolt not installing all of the way, getting stuck about 3/4 of the way in. I’ve seen that happen with standard 5-piece as well, but combined with the spinning hangers and now this other issue, my overall impression is fairly negative I had similar issues with the first couple and changed my approach. Having placed a bunch of Triplex bolts in the past, which had similar issues with the hangers spinning (if the hanger doesn't get pressed into the rock well enough), I tried what worked with them: Giving the edge of the hole a little bit of a counter sink. Just reaming the edge of the hole a little extra with the same bit seemed to work. I think this allows the sleeve to seat a little deeper and thus the hanger can fully engage the rock. Have only placed a handful since but it's seemed to have done the trick. Also, make sure you back the cone off a good bit before hammering the bolt in. This will prevent the sleeve from engaging as you hammer it in (the likely cause of your friend's problem). Same as for the 5-piece.

|

|

|

Jim Day

·

May 5, 2025

·

Fort Worth, TX

· Joined Jan 2020

· Points: 3,159

·

May 5, 2025

·

Fort Worth, TX

· Joined Jan 2020

· Points: 3,159

Tal Mwrote:- Loosened one after installing to replace the hanger and was unable to re-tighten down. I tried pulling out on the hanger while tightening down but that didn’t seem to work either. I’ll try and get a tuning fork to get better leverage in the future, but is this common? Is there a way to avoid this?

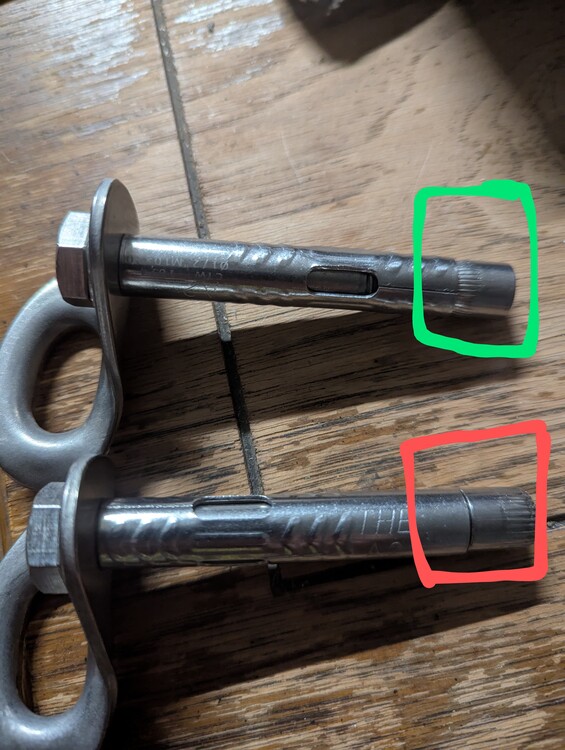

Probably a dumb question but do you have the cone screwed on the right way? It's easy to misassemble these bolts. Also the cone is only like, 12mm (or slightly under) whereas a 5 piece is ~14mm, so on a 5 piece the cone itself is actually gripping the rock. But assuming the cone is facing the correct way, I imagine your best bet is to get a pry bar behind the hanger to pry the bolt while unscrewing. Hopefully the cone will engage with the sleeve and the stud will unscrew from the cone

|

|

|

Tal M

·

May 5, 2025

·

Denver, CO

· Joined Dec 2018

· Points: 5,098

Jim Daywrote: Probably a dumb question but do you have the cone screwed on the right way? It's easy to misassemble these bolts. Also the cone is only like, 12mm (or slightly under) whereas a 5 piece is ~14mm, so on a 5 piece the cone itself is actually gripping the rock. But assuming the cone is facing the correct way, I imagine your best bet is to get a pry bar behind the hanger to pry the bolt while unscrewing. Hopefully the cone will engage with the sleeve and the stud will unscrew from the cone Not a dumb question at all, I do indeed have them installed correctly (noticed I had a few backwards before I camoed them and went and corrected all of them). It tightened down correctly initially, it's just the retightening down that's an issue. Yeah I didn't have a prybar with me when it first happened, but I'll be heading back to that same route/anchor this weekend and will bring a little one and see if that fixes it.

|

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook