New Sleeve Bolts

|

|

Dan Merrick wrote: This isn't actually how it works. Because the drill is hand-held the bit does not drill a round hole, it actually creates a form called a Releaux Polygon. In the case of a normal two-edged bit this is in the form of a triangle with curved sides and measured across the diameters at any point will be the size of the bit (plus a small amount) BUT a round object of the bit size will not fit into the drilled hole. Using a standard 12mm masonary bit a 12mm bar will not fit into the hole however if you measure the hole with a vernier caliper it will read around 12.5mm. You see the same effect when starting to drill in metal with a normal bit especially going through sheet metal. To fit in the hole a solid round object must be about 11.8mm dia and this is actually the size used for wedge bolt shafts. |

|

|

I ordered a couple yesterday to check out. Do you have a rough estimate when the 12mm x 120mm sleeve will be available to purchase? |

|

|

Jim Titt wrote: Yep, in reference to the Wankel engine I call the Releaux Polygon a Wankel hole. Happens with two flute bits. |

|

|

Tobias Duffy wrote: Hi, I'd give it around a month to 2 months till its on the shelves at HowNOT2. |

|

|

Much as I’d like to be a curmudgeon and disparage these, I placed a few and like them pretty well. They hammer in about like a wedge bolt (much more easily than a 5-piece) tighten quickly, and seem pretty solid. The hex head is pretty big (.67”/17mm rather than .56”/14mm on a 1/2” 5-piece), but still low profile enough that it doesn’t interfere with clipping or a carabiner on the hanger. I was initially skeptical of the knurling on the cone, but that seems like a nice feature that will reduce spinners. I’ll be interested to see how well they hold up, and if they stay tight over time, but initial impressions from placing a few were positive. |

|

|

Regarding hangers, the Powers 1/2” 5-piece sleeve bolt fits into a 3/8” hanger. Is that also the case for these CT sleeves? |

|

|

Does anyone know where these bolts are manufactured? IE Taiwan or west Taiwan? (-500 social credit) |

|

|

J W wrote: Yeaaahhhh... They say you're not supposed to do that :) Just use a 1/2" hole hanger like the Fixe hangers |

|

|

J W wrote: From Fixe website: |

|

|

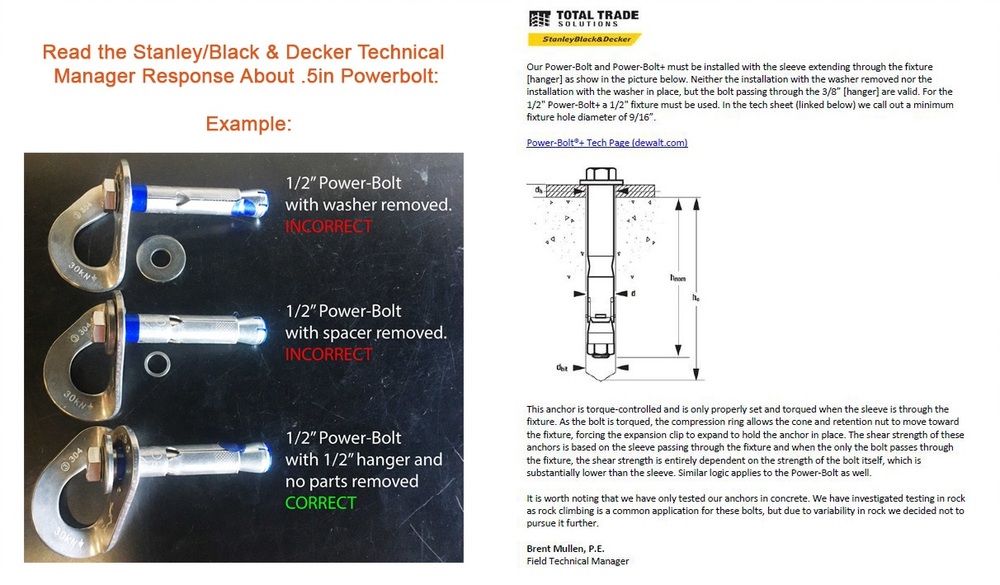

You're right it's common practice and has been debated a ton. For one thing it's weaker because you lose the added strength from the sleeve (but it's still strong enough with just the shaft, definitely stronger than a 3/8" wedge bolt). I think the bigger issues are that it's more likely to loosen/ become a spinner, and whether or not you're getting the right thread engagement (though they say you can make up for this by removing the thick washer). |

|

|

The CT bolts specifically suggest using a 10mm hanger on the 12mm bolts (8mm hanger on the 10mm bolts). I think most 3/8 hangers would be fine. I tried them with fixe 3/8 climb tech 3/8 and petzl 10mm. In practice with 5-piece I’ve seen no difference between using 1/2” hangers with the washer, and 3/8” hangers without the washer. |

|

|

Peter Thomas wrote: Doh! Well, there you go for the CT bolts. For 5 pieces, there may be no difference, but maybe there is. I've heard lots of different opinions, but a lot pf those opinions are coming from biased people who have been doing it a certain way for years, and don't want to hear that the manufacturer/ retailer is saying that those ways are not valid. I've come across lots of old 5 pieces with 3/8 bolts which have become spinners, while I've come across none (that I can think of) 5 piece bolts with 1/2" hangers which are spinners. But that's because pretty much every 5 piece I come across is a 3/8 hanger, and I almost never come across 1/2" bolts with 1/2" hangers (unless they're ones I placed myself). If there's any chance 1/2" hangers are a better pairing, that's enough for me to consider the manufacturer's statements. But, has someone done some experiments/ testing? |

|

|

Climbing Weasel wrote: Hi, Our Climbing Taiwan sleeve bolts components are all manufactured in China. We further inspect, process, and assemble them here in Taiwan. Our wedge bolts are completely manufactured here in Taiwan. |

|

|

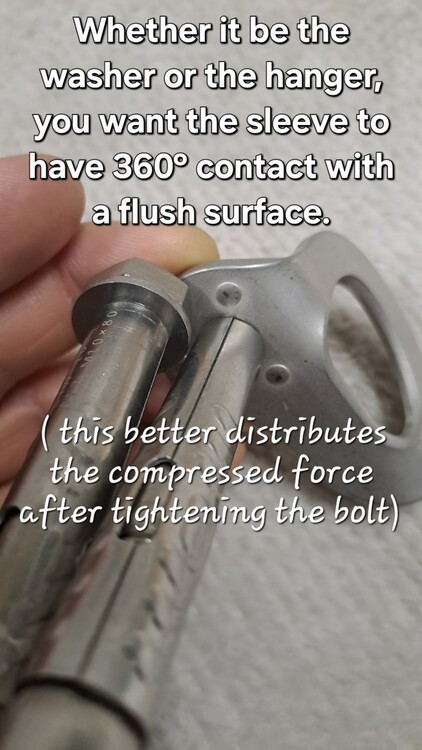

Hello. Multiple things and updates to share: We’ve done most of our testing of our 10mm sleeve bolts with 8mm hangers, and 12mm sleeve bolts with 10mm hangers, where the hex bolt shaft sits right on the hanger and the sleeve end buts up against the bottom of the hanger…hence the current chart on HowNOT2’s website, (which will soon be updated with new specs) ---This weekend we’re scheduled to do some additional testing of our 10mm sleeve bolts with 10mm hangers, and our 12mm sleeve bolts with 12mm hangers. I’m expecting similar break results. I’m sure the sleeve going through the hanger bolt hole will add some additional strength in shear, but won’t do anything much for tension.*** If using a hanger, the same size as the sleeve bolt, I would add that it’s important for the sleeve to fully fit inside the hanger bolt hole, that way there is 360 ° engagement of the sleeve against the washer (see pic). It’ll help properly dissipate the compression force when the bolt is being torqued. *** If you want a 2nd opinion to confirm, you can watch Matt’s, who is an engineer (Mountain Mullet/ Boltuh Downunder) Expansion bolts: Wedge bolt vs Sleeve bolt [Climbing bolt basics] video. For our 10mm sleeve bolts, the hex bolt is a 7.9mm diameter, and the sleeve outer diameter is about 10mm. So you’ll need either an 8mm hanger, or a 10mm hanger. A “3/8 inch“ hanger will work if their hole can fit 10mm things. For our 12mm sleeve bolts, the hex bolt is a 9.9mm diameter, the sleeve is about 12.10mm diameter. You can use 10mm, 12mm, or 1/2“ hangers. We also have come out with a ½” sleeve bolt in just 304SS, which uses all the same inner components, but just a wider sleeve. (I’ve included some measurement pictures.) We’ve done some tension testing of our 12mm sleeve bolts in ½” holes because several asked. Basically, in the hard rock test, the bolt broke full strength, 49.09kN. In our soft rock test, the bolt pulled out at 38.56kN. But there were red flags for the installation: First, the bolt readily goes in and out, (which would suck for steep installations). Additionally, there could be concern if the hex bolt were to get loosened + the cone not expanding the sleeve anymore= the whole bolt would pull straight out. Last, they’re a bit trickier to tighten because you don’t have as much friction of the sleeve against the drilled hole. --- Definitely strong enough in terms of strength, yet strength shouldn’t be the only determining factor. I still don’t think its best practice for permanent installations. ***BUT, the same concept is used in removable bolts. So, if anyone was looking for some simple removable bolt options, then this could be one of them. Speaking of testing in soft rock, we did some over the weekend in sandstone. Like, we have testing data of what our current sleeve bolts break at, but the rest would really depend on your substrate type and the quality. Going with longer sleeve bolts can yield different results (so we’ll do more testing in different substrates when the longer bolts arrive). With our 12mm sleeve bolts, we got a range (in tension) of 26kN to 41kN from rock failure, and 48kN in shear (bolt pulled out). For our 10mm x 70mm sleeve bolts, got 24kN in tension (bolt pulled out), and 33kN in shear (bolt pulled out). So like the numbers are a little bit all over the place with softer substrates. When we get a better setup, we want to test in concrete samples for more cleaner data. |

|

|

Jim Day wrote: Just an observation from this announcement on Fixe Hardware's website. So basically the reason for going with a 1/2" hanger on the 1/2" Power-Bolt is because the "shear strength of the anchors is based on the sleeve passing through the fixture [hanger]", so basically they're including the additional material the metal sleeve has + the hex bolt for their higher shear rating. Like, I can see how that makes sense for like their 4.75" long bolts where there is a long enough metal sleeve where the hanger sits, HOWEVER on the 2.75" one the hanger sits on the nylon compression ring and little metal spacer (as pictured in their own example)....so like what any good is it doing there???... Like if there was a longer metal sleeve that continuously ran inside the hole, then the additional sleeve material would be beneficial. |

|

|

Excited to try these - I've been looking for an alternative to the Powers/DeWalt 5-piece (which is my favorite bolt, but $$$). One thing I like about the 5-piece is the cone has notches and it is "pre-expanded" (as in, it is a tight fit in the hole and compresses as it's hammered in). This seems to reduce spinners or problems tightening, but moreover, when you tighten the stud and it passes through the cone, the stud forces the cone to remain expanded thus providing a secondary point of expansion in the hole in addition to the sleeve expanding over the cone... Or so I've been told. Still, this CT design seems simple and well-thought-out and I'm excited to try them. Ease and reliability of installation, along with how they fare over time (do they loosen or stay tight) are my main questions - especially in softer rock. What is the diameter of the stud part of the 10 and 12mm compared to the similar 5-pieces (3/8 and 1/2")? My only reluctance to use 3/8" 5-pieces is that stud is so skinny. Is HowNot2 to be the exclusive distributor in the US? |

|

|

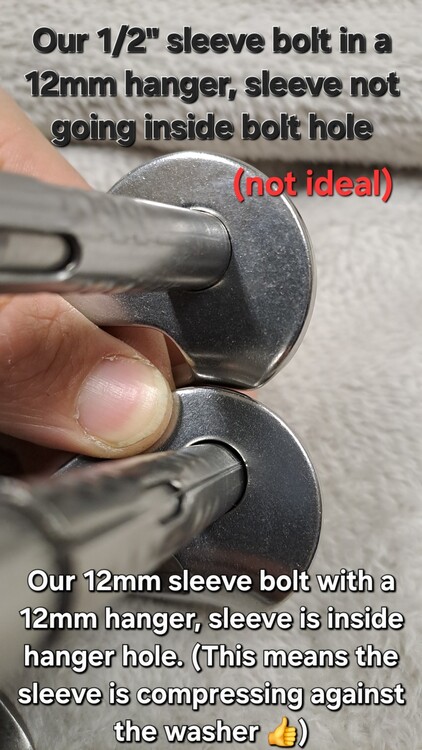

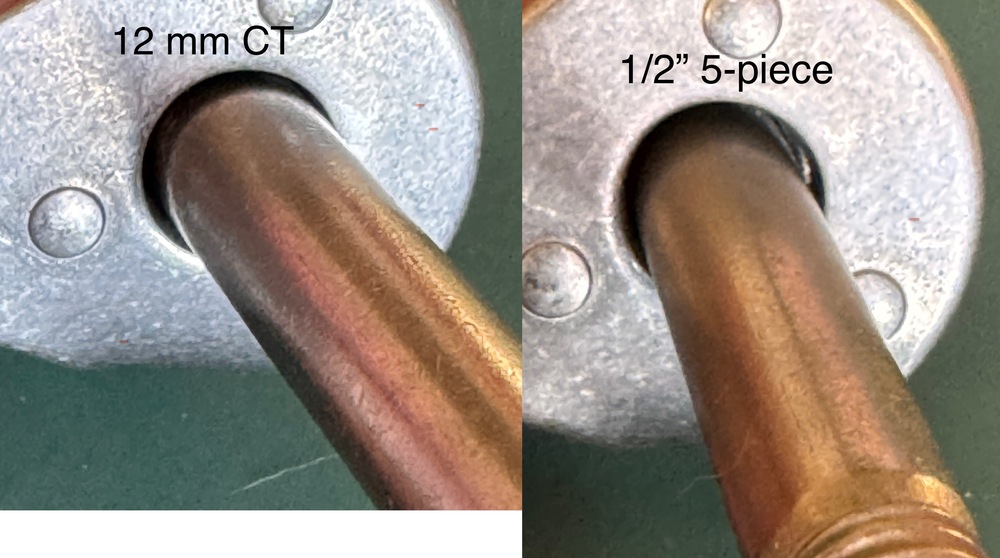

I’ve had the chance to place about 50 of these. For the price, I think they’re pretty great.

Ease of installation—5/5 How they fare over time—unknown at this point (to me) Regarding stud diameter, I’m afraid I don’t have calipers, so there’s definitely some fuzziness to my measurements, but the 12 mm CT (sorry, I don’t have 1/2”) stud appears very close to 9 mm. The 1/2” 5-piece stud is closer to 8 mm. So an imprecise, but accurate, answer to the question of how 1/2” 5-piece studs compare to 12 mm (or 1/2”) CT is that CT studs are larger. The above picture shows the studs in the same 3/8” hanger. You can see a bit more room on the 5-piece. |

|

|

Great! That's good news. I wonder if the 10mm (v. 3/8") is similar. Thanks for posting up. |

|

|

J W wrote: still sitting on the fence regarding these for exactly that reason. i’d hate to place a bunch and find out five or ten years later that they don’t work as well as the 5-piece dewalt (which, just like for josh, are also my favorite mechanical bolt - but they are definitely way expensive!) |

|

|

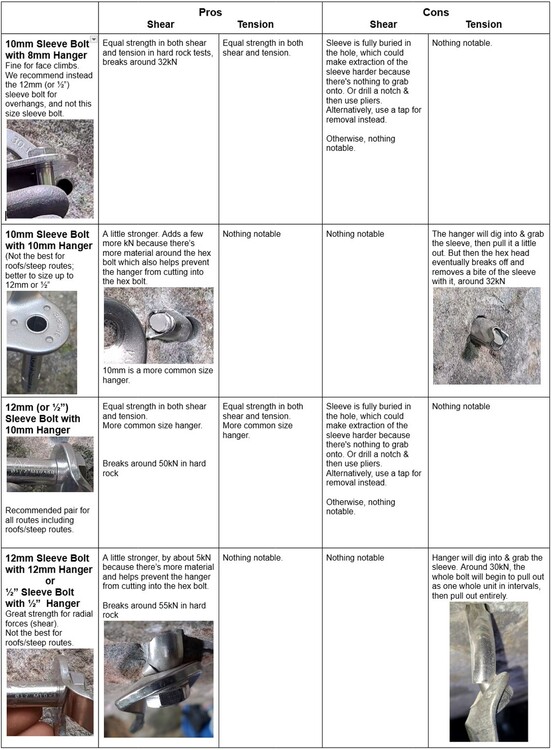

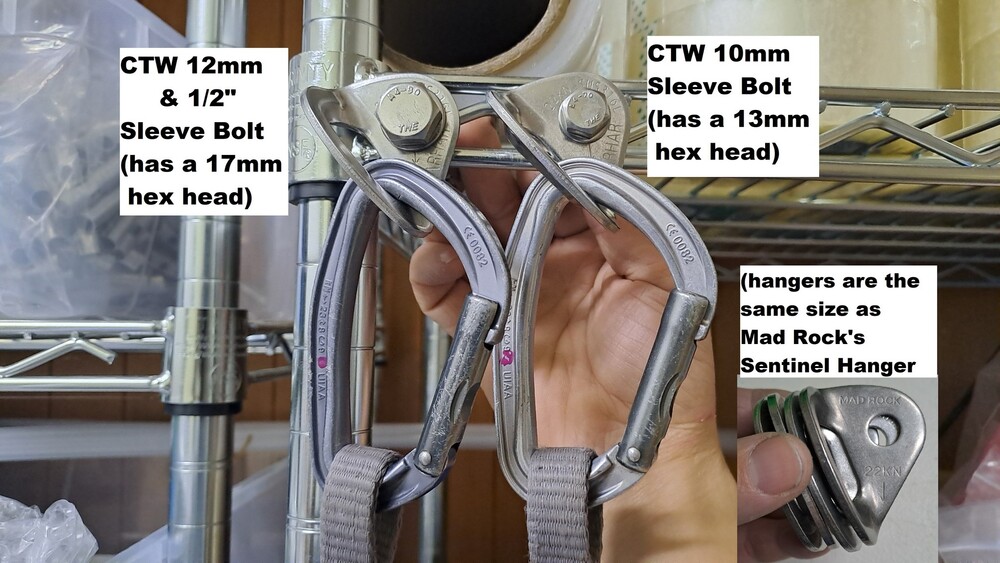

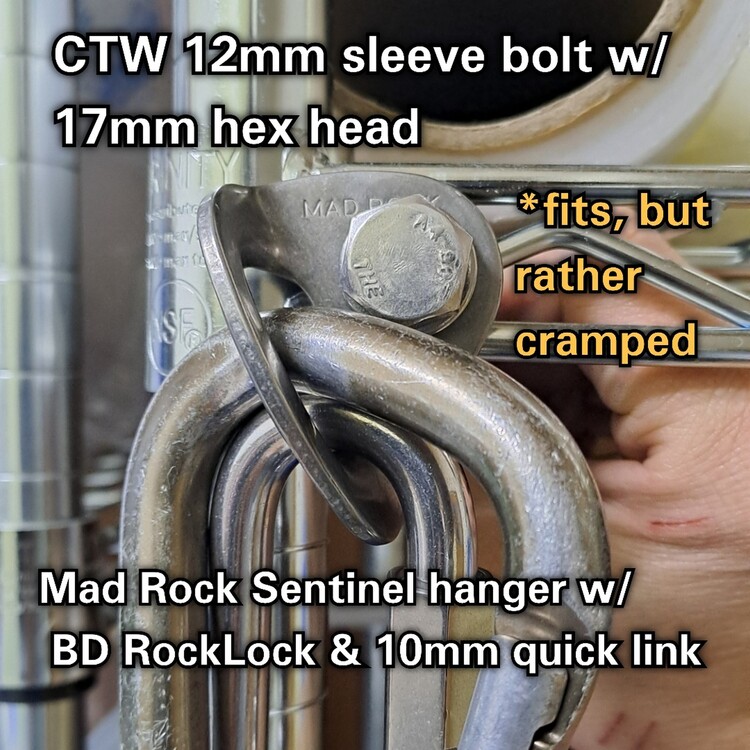

Hi. We did some testing of our sleeve bolt where the hanger goes onto the hex bolt vs the hanger sits on the sleeve. There’s pros and cons to each. Yet everything in our tests so far exceeds 25 kN. See our chart below: ( doc link also HERE) ***REMINDER: If sizing up the hanger (e.g. 10mm hanger for 10mm sleeve bolt, 12mm hanger for 12mm sleeve), it's pretty important the sleeve actually fits inside the hanger hole and is situated inside before installation. If it does, it means the sleeve end will be pressing against the bolt washer, in this case a full 360°, which is what you want for better distribution of force. However if the sleeve isn't fully fitting inside the hanger, it'll offset the force on one end of the sleeve, which is not ideal. So a possibility (when hammering it in and/or tightening it down), is section of the sleeve can begin to deform by partially getting stuck in the hanger hole and the adjacent section sorta gets smashed-up, which subsequently affects the installation. And if using a smaller hanger (i.e. 8mm hanger for 10mm sleeve bolt, 10mm hanger for 12mm or 1/2" sleeve bolt, etc), it changes the force distribution of the sleeve end to the hanger itself, but still a full 360°. (We actually prefer this configuration. It's definitely strong enough and the most versatile). *** I’m sharing some questions we've received and our responses (which we’ve answered to the best of our current knowledge and data) : 1. Will the larger (17mm) head interfere with carabiners/smaller or curved hangers - like the old PETZL’s and Climb Tech’s)? Both bolt sizes should be fine on smaller hangers. We tried them on the small Mad Rock Sentinel hangers and there's enough space for a quickdraw, or even a thick BD RockLock HMS carabiner. Next we tried adding in both a 10mm QL and a HMS carabiner; it’ll fit inside, but quite cramped, and there might be limited mobility on the carabiner. More Ideal would be the 10mm sleeve bolt and an 8mm QL on small hangers like that. (see attached images) 2. Will I get spinners or have other problems installing? Particularly in decent sandstone? A sleeve bolt “spinner” would either be the result of galling of the hex bolt & conical nut. Or some grit in the threads not allowing the cone nut to be drawn up. To help prevent, don't over-torque and clean the holes out. Make sure the nut or cone nut can freely go up and down the span of threads before installation.* A 2nd problem could be the sleeve isn't getting enough friction in the hole. The cone nut can be tightened just a tad so the sleeve gets a little extra friction in the hole, (but not tightened too much). But if the sleeve already requires a few taps or hammering to get inside the hole, then there's sufficient friction. *This is pretty important in general for any wedge and sleeve bolt. Before installing your bolt, check to see if the nut (on wedge bolts and sleeve bolts) or the conical nut (flush head sleeve bolts) can actually go up and down the threads without any galling. Bolt threads can get damaged via transportation, bouncing around in bags with other bolts, rough handling, etc. 3. Will I be able to remove these bolts easily? I’ve inferred that it’ll actually be easier than 5-pieces… They're relatively easy to remove. Depends on several factors. Basically, whatever amount of friction the sleeve had going into the hole, it'll have about the same coming out. Sleeves that went easy, will slide out more easily, vs ones that had to be hammered-in will have more friction to overcome. Matt from Mountain Mullet talks about some sleeve removal methods HERE. If the sleeve is very snug, and working with a pair of needle-nose vice grips has proved ineffective, then using a thread tap will work: A 7/16” tap for our 12mm & ½” sleeve bolts and a ⅜” tap for our 10mm sleeve bolts. 4. IF they loosen slightly… how easily will they slide out of their holes unintentionally? I do like that a slightly loose 5-piece tends to stay put - peace of mind. If the hex bolt loosens slightly, the sleeve bolt should still stay in the hole provided there's friction holding the sleeve in place. In addition, the cone nut is still expanding the sleeve. So it takes 2 prerequisites to be met before there's a concern: a loose hex bolt + the hex bolt needing to be pushed in so that the cone nut isn't expanding the sleeve end anymore. Even so, if the sleeve is held in place well, then if there's outward force on the hex head, it'll drive the cone back into the sleeve end hence expanding it and holding the bolt in. 5. What will the long term reliability of them be? ESPECIALLY in sandstone… The bolts are fully stainless steel, (no plastic components inside). So if there's no corrosion, then one other primary concern is weathering of the rock surface. But that affects bolts of all types (lesser so for glue-ins since it's one-piece construction). If the hole has extra depth available, essentially, the bolt can be loosened, any surrounding rock underneath the hanger chipped away to make a flush surface (if any), then the bolt hammered-in deeper, then re-torqued. (But this also affects wedge bolts too). Whatever the case, if someone has a system down to remove the sleeve bolts without damaging any components, then it's possible to completely remove them, drill the hole deeper, and reinstall them. Or just replace it with a glue-in…but we're talking about decades of weathering till it reaches that point…depending how quickly the rock weathers away. And if there's concern about widening of the hole for some reason, we have performed tests of our sleeve bolts in wider holes and they can still perform full strength given they're long enough for the substrate type and torqued sufficiently. The other matter is that the right diameter bolt needs to be selected for the loads it'll see. Sleeve or wedge bolts installed in overhangs should be sized-up. That’s because some class 2 leverage happens to hangers seeing axial loading. For better longer term reliability, in general be sure that the right type of anchor was initially chosen for the substrate it's going in. To be frank, sometimes this requires actual destructive testing, or better understanding of the substrate you're working with and how it performs with different anchor types+design, length, & diameter. Last point to add is drill your hole straight, perpendicular to the hanger's surface. These sleeve bolts will also expose angled holes the same same wedge bolts do, which results of the head head/hex nut not sitting flush. They lack the feature of the nylon compression ring the Powers 5-piece have to make up for installer mess-ups like not drilling straight and over-torquing. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook