crack machine rec

|

|

looking to create a crack machine for myself to train on. any recs on crack sizes to include, and anyone have a recommendation on dimensions for building it. dont want it to fall apart on me lmao. my dad has all the tools and I’m going to cover material cost so I don’t want it to be absurdly expensive. i’ll probably make it 10ish feet long, and like 5 or so feet tall (though i don’t really know what height to build it, i’m 5’7ish)? thanks for any input. |

|

|

Just like a board, 12’ is much better than 8’ or 10’. Most crack machines are vertical or somewhat overhung. There are many designs online for an adjustable width crack machine, but a fixed size is fine as long as you can actually jam it. I rarely change the width on mine (it’s set at 1.5”, 5 degrees overhung). Start with a reasonable to tight hand jam (2-2.75” for average hands). A very slight texture is nice for simulating rock, but eats your hands and shoes more. If you’re thinking horizontal, make the jams pretty easy. Tight #2s or mid #5s if you’re doing offwidth. |

|

|

Luca DeMeglio wrote: If you know any contractors or have friends who work construction, you might be able to get some un-used16 foot long 2x8’s or 2x4’s. That was how we were able to make ours

I’m a bigger guy so if I’m training in the wide pa

We built ours from 0.75’s (shitty loose finger locks for me, but perfect thin hands for my partner) all the way to 6’s (good stacks for me, terrible for my partner)

|

|

|

|

|

|

thanks a ton garrett! |

|

|

I use two 10ft 2x10s for mine. There are two adjustable bolts on each end along with two in the center. I cut pvc pipe to use for spacers that cover the bolt threads. I can easily enough change configuration from hands to fists to off width. It takes about 10 minutes to change the size. It does have a little sway but it’s not super noticeable while climbing. |

|

|

If you're doing a horizontal crack, 10 ft. is not going to feel very long once you get used to it. Thats only two body lengths really totaling like 5 hand movements before you have to turn around. Patrick mentioned his racks a bit, when building the base try to think about triangles. Whenever you can angle the base legs out (making a triangle in the center) you will help control rack and shift. That means out away from the center point of the crack in both directions. So, in Patrick's crack machine, if you move the bottom of both leg sets out at an angle it will control rack and if you move the two leg bases away from the center this will control shift. Obviously, this means cutting angles instead of straight pieces but it's not super complicated, even 10 degrees will make a major difference. |

|

|

Bolting Karen wrote: thanks for the tip on the base. just to clarify though, i would be cutting the base and having it point away from the center, forming a greater than 90° angle with the center? yeah, i know 10ft in the long run isn’t very big, but our house ain’t very big, and im going to have to put it away in a storage closet after use every time so my family doesn’t get pissy with me. 10ft ensures i can lean it up against the wall at an angle for storage. |

|

|

Luca DeMeglio wrote: Honestly longer is obviously better but the 10ft works nice for me. I either attempt to go back in reverse (hard for me) or I just get two jams with palms facing the same side of the crack and cut feet. I can swap directions pretty easily to run laps. |

|

|

Luca DeMeglio wrote: exactly, like a tripod at each end |

|

|

+1 for ~5' tall. I built mine too low, a touch over 3', and I have to stack the bases on platforms to keep my back from hitting the ground when my arms are fully extended... |

|

|

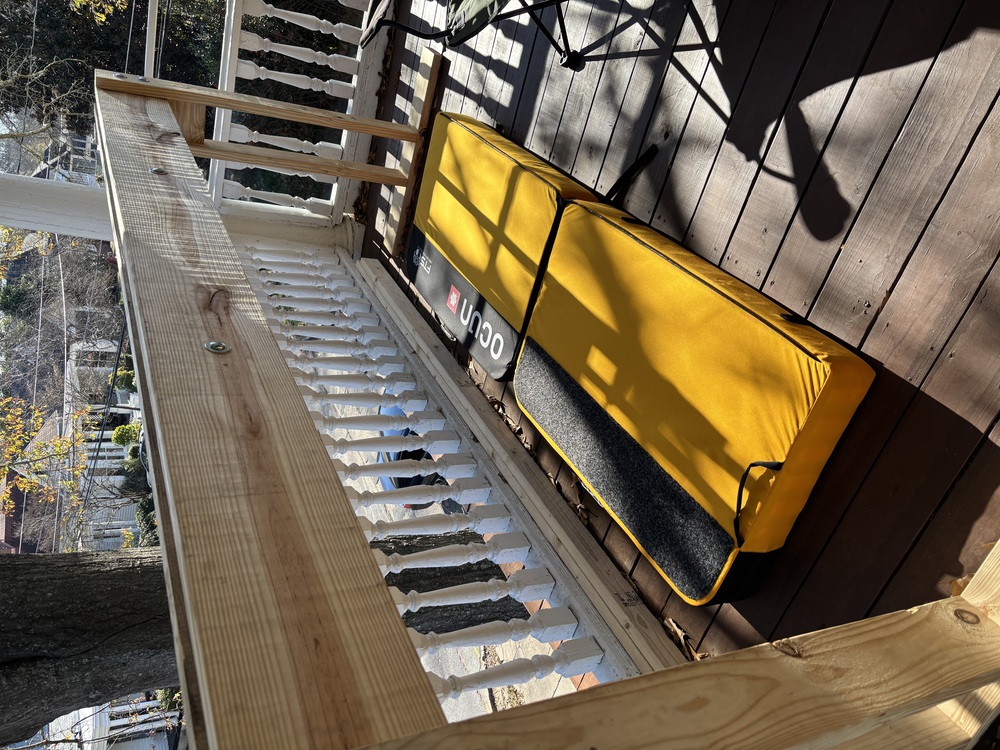

final product with it put together (extremely half assed). about the size of a #2. it sways a fair amount, but hardly notice it. i did add some staircase grip tape because its a little bit bigger than hands for me but way smaller than fists, huge mistake, my finger tips and palm are SHREDDED. cant do much hard climbing with my index and middle for a while. i just took off the grip tape and plan on just rocking some thick ass tape gloves. (it also has already taken a chunk out of my shoes). thanks to all who responded to give their 2 cents, stoked to expand it in the future to add fists. |

|

|

Looks nice. If the swaying becomes an issue down the line, you can reinforce at the base with some of these brackets: https://www.homedepot.com/p/Simpson-Strong-Tie-3-in-x-3-in-x-1-1-2-in-Galvanized-Angle-A33/100374962 I used one on each leg and have virtually zero movement |

|

|

|

|

|

Has anyone built something like this? I can’t find much info on a product but it seems like something I could DIY, but I don’t understand how this is “locking” in different sizes? |

|

|

Brian Anderson wrote: https://sicgrips.blogspot.com/2017/11/the-squeezebox-adjustable-crack.html?m= Not exactly what you’re looking for but the bones are similar and it’s an incredibly easy diy Also https://www.mountainproject.com/forum/topic/123540212/does-anyone-know-how-to-build-this |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook