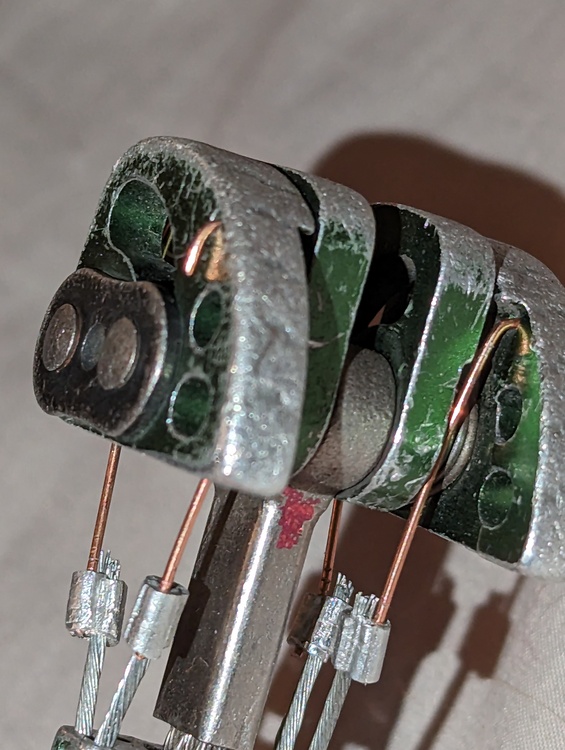

z4 trigger wire repair - how to remove old trigger wires?

|

|

Has anyone figured out how to remove the old trigger wires from a z4 in order to replace it? I've tried pushing from the outside, and pulling from the inside with pliers, adding lube, adding heat. They kind of seem to be welded in place, except for the fact that the wire will move ~1mm in the right direction but will not come all the way out. BD wants $28 to replace, so I want to exhaust all other options first. These trigger wires seem inherently flimsy and will probably break again. |

|

|

Guessing it is swaged. If you are replacing it anyways, why not just clip the wire on the internal side and push it out from the inside? |

|

|

The end of the trigger wire is a little bulb that sits in a recess, so you have to remove it in the other direction. In your photo the wire with the arrow has to come towards the camera. Replacing with weed whacker line worked ok with the #0.5. I drilled out the holes to 1/16" and used 0.05" trimmer line. The holes pass underneath the axle plates though, so however you terminate the replacement has to be low profile. Also the hole locations mean that any non-rigid replacement is going to rub against the cam springs at the start of the pull and not be totally smooth. |

|

|

Don't remove the hard wire! Just swage new flexible cable to them. I'll do this for you for $9, a fraction of what BD would charge you. PM to arrange. |

|

|

Austin Donisanwrote:Replacing with weed whacker line worked ok with the #0.5. I used plastic picture hanging wire (essentially thick fishing line) from the hardware store. Same idea, but no drilling required. |

|

|

Adam Flemingwrote: Do you still melt it to terminate the ends? On the Z4 does it nest nicely inside the lobe when you do that? |

|

|

Austin Donisanwrote: Yes, I still melted it. It doesn't nest flush, but it seems like it's out of the way enough. I haven't gotten a chance to test it because the cam is an offset in a size I don't use often. |

|

|

Austin Donisanwrote: Thanks a ton! This was the solution. Didn't realize there was a bulb pointing toward the camera. Just needed to move the wire in the opposite direction. 0.050 trimmer line is too fat to fit through the hole. I don't want to drill the hole bigger, afraid of screwing up and completely mangling the lobes. I did a proof of concept repair with sewing thread. This worked for about 10 squeezes of the trigger and then got sawed through by the movement of the lobes. Will need to go to the hardware store to find some kind of wire. |

|

|

Has anyone found a more durable/elegant/easy/non-destructive solution to this problem? Just recently spent about 8 cumulative hours threading Kevlar cordage that doesn't seem like it will last through 4 of these cams with even more on deck. Absolutely refuse to pay $15 per cam for this, especially given how quickly these seem to wear out. This is the first I'm dealing with it, and it could be the Z4 killer for me to be honest. |

|

|

I have had some success recently with using wire cable for hanging picture frames. Ended up tying a knot on each end and smashing it down some with pliers. Not the prettiest solution but it's holding up so far. |

|

|

What Gunkie Mike said above is the best plan, if possible. If you or a friend own Andy Kirkpatrick's big wall book, he details a number of suitable wires for various cam repairs. Don't want to reprint his work here for free. Might be worth checking his Substack, too. |

|

|

I've had success with 0.7mm fishing line (no drilling required). Melting the ends leaves it totally flush in the recess and seems to be holding up so far. |

|

|

I ended up getting some plain old wire from Home Depot (it took some searching to find wire thin enough) The repair seemed pretty flimsy, but surprisingly it has held up without re-repairing in the 8 months since I posted this question. |

|

|

I made a DIY video for this here |

|

|

|

|

|

Kyle Turgeonwrote: I'll report back in a few months. |

|

|

I ended up getting a Kevlar string product similar to what BD was using on the X4s from Amazon. It’s not kernmantle (sheath and core style) cordage but rather is braided. It was a real PITA to get it threaded through the trigger holes on the cam lobes but so far it’s holding up well. Here’s a link to the product: amazon.com/gp/aw/d/B07X9F17…;ref=ppx_pop_mob_b_asin_title&th=1 |

|

|

kit campwrote: Bumping this. I'm all for creative solutions but repairing these in kind is super easy -- you have to buy a cheap crimping tool and wire, but the same exact kit works for UL's, and it's easy to find wire and crimps that work for C4's. You don't have to remove the wire or reengineer anything, and the repair is as good as new (maybe for better or worse). I have been using some random wire that visually appears to be the same diameter and a cheap crimper like this https://www.amazon.com/Crimping-Swaging-Aluminum-Stainless-Assortment/dp/B07YHJ24B5/ref=sr_1_35?keywords=swager&qid=1695069037&sr=8-35&th=1 I'm not totally convinced it is always worth the time to repair these, I just find it faster and less of a hassle than sending them in. |

|

|

Ben Kraftwrote: I have that tool and while it's good for "on-the-benchtop" crimping, the nose of it is way too fat to work on a small cam like the Z4s. Specifically, if you leave the stiff wire in the lobes (as you would want to do, since this part isn't what breaks) and just attach new cable/wire rope", you can't get in there to crimp the mini swages. That's been my experience at least. Bigger cams e.g. large C4s are easy with this or other tools. |

|

|

Further to my comment above, I now have a customized, narrow nose crimping tool. so the tight confines of a Z4 cam aren't so much of a problem any more. If anyone wants me to repair their cam, just PM me. $9/cam for Z4s. $6 for C4s and Ultralights. Totems $19. |

|

|

Wow what a schmancy trigger wire repair by gunkiemike! He also does ice screw sharpening and shortening :) |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook