What Does Your Woody Look Like??? v3.0

|

|

|

|

|

Andrew Dwrote: Looks fantastic! I'm glad the hoist/chain system is working out. So much more sturdy than my local climbing gyms adjustable walls. |

|

|

Andrew Dwrote: I was just looking closely at the attachments of the chain as I was inspired by your wall, and felt concerned about the 4 Sheetrock screws in the D ring holding this entire thing up from crushing you. A lot would have to go wrong for it to fail, but that seems like a failure mode that could be remedied. Running a 1/2” machine screw through the wood from behind and attaching a climbing hanger would likely be a safer option. I’d also recommend doing away with the aluminum carabiners in favors of quick links on that chain. Nice looking build otherwise! |

|

|

Cory Nwrote: I don’t think they are Sheetrock screws, I think they are painted stainless. Two of them on each ring are 3-4” long and are through the header into the studs. The backup to all of that failing would be the winch itself holding up the board, which is also through the header and into the studs on beefy screws. I feel pretty good about it, but I suppose there is always a chance of getting crushed. I have since taken down almost all of the jugs and have added only small holds. The next step is filling it out with screw ons. I’ll post an updated pic later. I’ve been using the Crux app and have been loving it!

|

|

|

Andrew Dwrote: Sweet! Yeah it’s hard to tell from the photos so I figured I’d say something just in case! Happy sending! |

|

|

10x8 TB1 @ 40 degrees to fit my 9ft ceiling. Roof extension & extra plastic holds for warm ups / circuits. Tons of storage behind the wall and I can still park my car with a quick shuffle of the mats. |

|

|

Made this during the pandemic. The picture is dead on, so scale and angle are wonky (sorry). Most wooden holds were made by me out of scrap or a friend who is a far better hold maker than I am. Plastic holds I bought. 8 feet wide, ~37 degrees overhanging giving about 11 feet of climbing. Except for the summer because of the heat, I am on this thing at least once a week trying to hone in my endurance, got a few different circuits I run. Between the overhang and lack of jugs, easiest climbing comes in at around v3. I also have an adjustable crack that lowers from the ceiling above my garage door, I’m just too lazy to move the cars and lower it right now. It provides 3 different width cracks I can train on at about 10 degrees overhanging. Lowers with a 3:1 pulley system. It is opposite my board so I can easy transition from board to crack and back without stopping. |

|

|

Just wondering—has anyone here attached panels with threaded bolts rather than screws into wood? Coupled with splitting the panels into 4x4's I think that would make them a lot easier to place / replace. Just curious if anyone's tried it and how you approached it. |

|

|

Dan Schmidtwrote: How is that different than a T-nuts? |

|

|

Andrew Rwrote: I'm referring to attaching the panels to the frame, not the holds to the panels. T-nuts might work for that, too, I'm just wondering if people have messed around with the design and curious to see what it looks like. |

|

|

Bolting your wall to your frame is a lot more work if you are using wood framing. The wood blocks you would use to attach your TNuts to bolt the panels to the wall end up getting in the way of your T nuts for your holds. I like using Fast Cap power head screws for panel attachment to wood frames. The square drive ones in 2” - 2 1/2” length work great. |

|

|

Kevin Strickerwrote: I’ve built three boards this way, the traditional Moon Board T-nut style. For the next one I’m actually not planning to use T-nuts. Lonestars and screws / extra set screws have worked great for me and provide more freedom for hold placement / density.

|

|

|

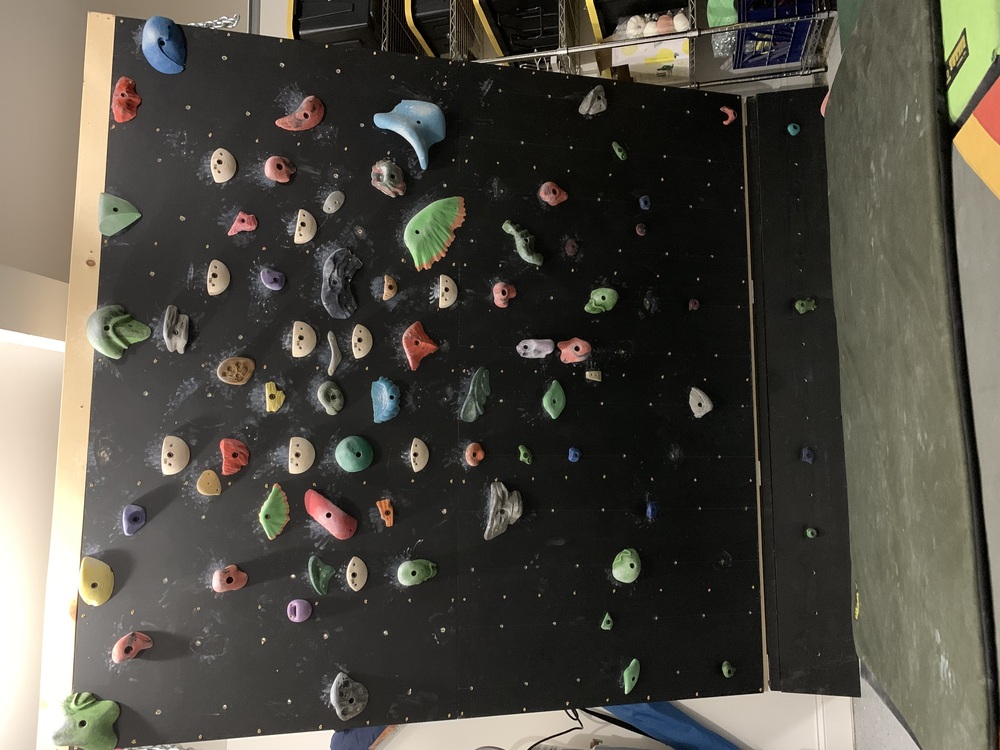

An updated picture of my wall. Could use some more holds on the bottom half, but I’m pretty happy with where it’s at for now. |

|

|

Owen Houdyshellwrote: Some nice holds on there! |

|

|

Andrew Dwrote: One big suggestion- turn half of your holds the other direction. If you look 4 columns in from the right side all your holds are downpulls or sidepulls angled 45 degrees. Switch a few to gastons. You have almost zero non-juggy underclings and could use some feet up the board. If you look at the top left side all your holds face almost the exact same angle so there won't be big differences in movement. I'd also suggest some dead vertical sidepulls. |

|

|

Karl Walterswrote: This is a good suggestion, thanks! I was thinking about adding some gastons but I definitely could play around with mixing it all up. I wanted the board to be mainly hard crimps, but you’re right, there is not much variety in pulling. |

|

|

|

|

|

Am I allowed to use this thread to seek advice on converting a space to a training area (using wood, of course)? Please provide guidance or prohibition, Woody Havers. |

|

|

Trevor Kerberwrote: Trevor, feel free to gain inspiration from this thread, but for advice regarding your specific case, it may be best to start a new thread. |

|

|

Aaron Lieblingwrote: Is that hydraulic? |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook