To recess or not recess glue-ins?

|

|

Agree, real time knowledge here. |

|

|

John Byrneswrote: ah ok makes a lot of sense! I had thought otherwise |

|

|

I made a video with 10mmx90mm SLB un-twist extraction using Liquidroc 500+, AC100, and glass capsules. Unfortunately I totally botched the glue capsule installation, but finished the video for the difference in un-twistability between liquidroc and ac100. In summary, the ac100 was pretty easy to untwist with a 42" crowbar. The liquidroc was more difficult, but still was able to untwist/ leverage out without sheering off the eye. Full video here: |

|

|

Thanks for another great contribution Jim. Love it. |

|

|

Jim you can make a tool like this to make the glue capsule install painless. Clevis with a 1/2 - 20 thread and a 3/8" slot. Filed to fit snug on the 10mm bolt. Use low rpm with the drill and it goes right in. Spin too fast and you pump the glue out of the hole. Raumer makes a tool for their 10mm bolt that just needs a slight modification to work with the Bolt-Products SLB. I think this possibility to replace the SLB this easily is a strong argument for their use! |

|

|

timothy fisherwrote: Thanks Tim! I think i already have all those pieces so I'll try it out Also, what's the max SLB length you can use with those capsules in my video? I have 7 or 8 more pf them. Can I use 120mm SLBs, or should I cut them down to 90 or 100mm? Or can i use 120mm with 7/16 drilled hole? |

|

|

There wont be enough glue to use longer bolt. I cut them to the length of the capsule to make sure the glue fills the hole. I have only been using these in very hard rock and have had some trouble with 7/16 hole. Ream the beginning of the hole well. Or use 12mm bit. |

|

|

Jim Daywrote: Jim, was there a lot of helium in the air the day you made that video? Your video illustrates the trade-off: Manufacturing a helical groove into the shaft is cheaper (compared to concentric rings) but then an un-notched bolt can be unscrewed. Thus notching is necessary, increasing the net cost and negating the material cost saving. As I've posted several times previously, twenty years ago I did a very similar test with Tortuga Ti bolts. Using a crowbar I made them spin until I could spin them with one finger. But I couldn't pull them out with the crowbar because the grooves on the shaft were concentric, not helical. So the thing to keep in mind is that none of the glues/epoxies we use actually bonds to the metal well enough to strongly hold the bolt in place. Bolts are held in place mechanically, by the glue filling the grooves and voids in the bolt and then hardening. |

|

|

I dont believe Mr. Titt or anyone else will agree that the Bolt-products SLB with their helical groove, require notching. The angle cut on the end of the bolt resists rotation significantly. An industry standard for glued in treaded rod btw. |

|

|

timothy fisherwrote: And to be fair, I re-cut the bolts at a less-steep angle for this experiment (I was trying to get them all to be 90mm as required by the glue capsule but I didn't do a great job re-creating the angle) so I'm not sure how much harder it would have been if I kept the factory angle. I placed a crossover bolt a few months ago and realized the placement causes rope drag, so I'm going to see if I can unscrew/ pry that out next. |

|

|

John Byrneswrote: Do you think there can be a benefit to notching and fully encapsulating a welded bolt in epoxy for corrosion resistance? The way we’ve done is notch cause of visual preference but with welded bolts intentionally making sure its sealed completely due to our corrosive environment. |

|

|

Belay Drewrote: The ONLY material that is safe for Puerto Rico is titanium, and those bolts do not need to be recessed. The (un-notched) titanium bolts we placed on Cayman Brac 25 years ago look brand new. You do not need to recess the Ti bolts for any reason. We have two routes (that I can think of) that have notched bolts. In both cases the bolts are harder to clip, and several placements result in cross-loading the top biner. |

|

|

John Byrneswrote: ONLY titanium? Sounds excessive, definitely something that can be decided on different factors but the stainless 1/2” expansions that have been installed by original bolters are still going strong, and are now showing signs of rust 15+ years later. Rebolting is being done in titanium. So 15 years for signs of rust on expansion bolts that makes contact with rock. Thinking having stainless glue ins will last a bit longer. Would there be any correlation to glue ins lasting longer than expansion bolts in corrosive environments? Keeping mind here climbing community consists of like less than 100 frequents climbers, there’s really no resource to bolt only titanium. |

|

|

Belay Drewrote: You aren't encapsulaing the weld, just stopping anyone seeing if has corroded. Protecting steel from corrosion is a widely used industrial process and very difficult to do well, just burying the weld in a load of resin grout is doing nothing but hide any problems. |

|

|

Belay Drewrote: It's not excessive. It's practical and economical compared to bolting with stainless and knowing that the route will need to be rebolted in 15 years, and assuming someone else will do the work and hoping no one dies because a bolt breaks when you could have prevented it.

Not strong, already weakened. Stainless bolts that show signs of "rust" are no longer safe. Many bolts that show signs of rust on the outside have already cracked behind the hanger. You need to do some research. Your arguments have all been debunked 10 years ago. It's all here on Mountain Project if you take the time to look. The Access Fund guideline: If stainless steel bolts show any signs of corrosion, then developers should be using titanium.

If you're rebolting with Ti, why are you not bolting with it the first time? Stainless glue-ins might last a bit longer but on Cayman Brac they seemed to corrode pretty much at the same rate as the expansion bolts, it's just that the corrosion was harder to see. Contact the ASCA and see if they will subsidize or even GIVE YOU titanium bolts. |

|

|

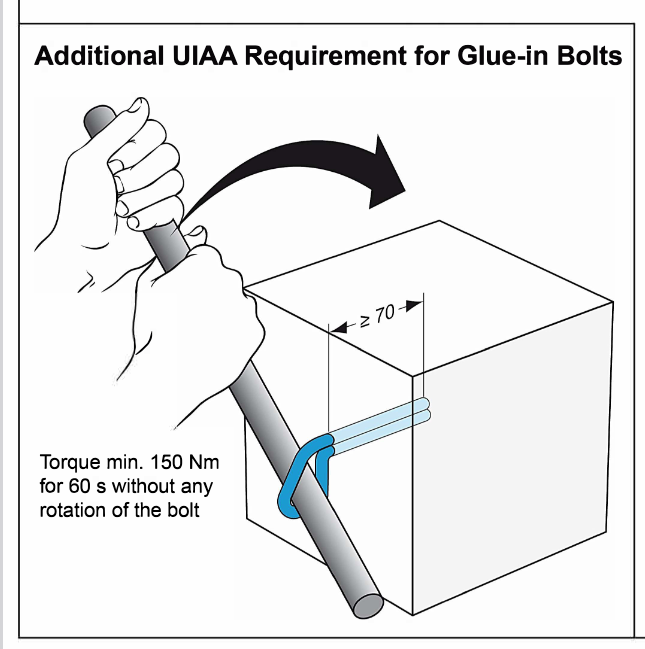

timothy fisherwrote: I agree, it they can pass this test. https://www.theuiaa.org/documents/safety-standards/Pictorial_UIAA123%20Rock%20Anchors_2024.pdf |

|

|

John, do you have any info on distance from the ocean for titanium vs stainless? Have there been discussions about at what distance from the coast titanium is mandatory? Costal bolting in Puerto Rico is in titanium. Inland is mostly 316 stainless steel with galvanized steel on the occasional route. |

|

|

Heliodor Jalbawrote: I’ve heard a 75 mile proximity to the sea used as a guideline by a European materials scientist some years ago |

|

|

Past Userwrote: Which we all laughed at, nowhere in the UK is 75miles from the sea. |

|

|

John Byrneswrote: In PR we have 2 OG crags five miles of the coast in a straight line, one is in a forest and one is at a higher elevation, both are protected from winds coming from the ocean. The one at higher altitude is rusting at the surface in a very uniform way. The one in the forest seems more affected by the acidic nature of the rock than ocean breeze, since on the same single route you can find badly pitted and rusted or even cracked bolts and while other bolts on the same route look fine. Ive even seen older galavanized glue ins with no signs of rust will the stainless expansion in the same crag are showing some rust. I understand rust means loss of material, but where is the super good enough line? For what it’s worth the new crag we are developing is also 5 miles of the coast like other crags but we are looking at the rock whenever choosing to use titanium and also putting one titanium bolt on every top anchor. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook