Photos of BEAUTIFUL HARDWARE pt2

|

|

The point is that it does take two for an anchor to be considered redundant. I’ve seen the pull-out/ failure test results with modern glue-in bolts, also often greater forces than 50kn. To borrow the above logic from the above posters, why haven’t we adopted a new standard to just use one bolt at our anchors? |

|

|

Past User wrote: Because you can see when a quick link is unscrewed and fix it, you can't see what's happening inside the rock. |

|

|

Past User wrote: Because we can’t xray see through rock to ensure a bolt is in good rock, not completely rusty, installed correctly, etc. but we can inspect the entirety of a quicklink before we commit to it solely. |

|

|

Drew Nevius wrote: The technique for splatter that I found works easiest/consistent (for me at least) is remove the button from the spray paint can and then depress the tube with needle nose pliers you don’t have to try depressing the button gently etc and the paint just splatters out. |

|

|

Past User wrote: The point again....The single QL is likely stronger than even 2 carabiners. The idea is "bomber" hardware can be trusted just like those non redundant items are every day. |

|

|

Past User wrote: Because we are chicken. Just about everyone reading this will fall all day long a single bolt (first 2 or 3 bolts of most sport climbs) that if it failed they would hit the ground but get all scared when loading a single bolt with their body weight to rappel. I would be happy with a single glue in bolt and I have no doubt that one glue in bolt is much more reliable than the 2 1/4 bolts of yore. I think if we had started with 1/2 bolts a single bolt would be the current standard today. |

|

|

Past User wrote: There is a difference between strength and reliability. Bolts, which we don't like to trust just one of, are ridiculously strong: they can reach 40+ kn. In contrast, the climbing rope, which we trust as a single point of failure, is way weaker than that, often around 20 kn, or less when knotted. Belay loops are generally rated to 15 kn. I don't know how strong a tree is (say a medium sized one, 8 inches in diameter), but I would bet it's less strong than a 40+ kn bolt. The reason we trust some life-safety objects as single points of failure is not because they are sufficiently strong (otherwise we would always trust bolts as single points of failure), but because they are sufficiently reliable: they rarely deviate far enough below their typical strength to be dangerous. And on the rare occasions they do (eg your rope is coreshot, your harness is severely frayed, the tree is dead/uprooted), such deficiency is obvious with a quick visual inspection. This is not the case for bolts. While they are fairly reliable, there are still things that can go wrong and result in them being fairly weak. Eg not mixing glue properly, sediment in the hole interfering with the wedge-clip mechanism, freeze-thaw action in the hole loosening the rock around the bolt. Note that all of these possible failure mechanisms are not something you can notice with a quick visual inspection (or any visual inspection). These possible failure modes are the reason we prefer not to trust bolts as a single point of failure. The point I am making is that stainless quicklinks are more like rope/harnesses/trees than bolts. They are extremely reliable and basically never fail under loads that climbing can generate; the only exception I know of is when they're unscrewed, which you can always tell with a quick visual inspection, unlike with the failure cases for bolts. |

|

|

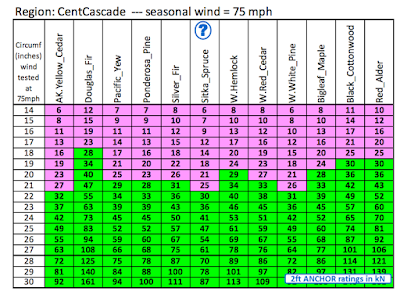

Alex Fischer wrote: You'd likely be mistaken, a healthy and well rooted 8 inch diameter tree has a circumference of ~25 inches. Estimated strength for this size is between 50 and 80kn depending on species. A good friend of mine wrote an article on tree strength, the figures you'll see tested there weren't to failure so you won't see that high of numbers in the article but you can see estimates on this chart based on wind load. For the most part I agree with you regarding quicklinks, assuming the links are of high quality. If I'm using a single point quicklink I will use a 3/8" or 1/2" link and be sure to loctite the threads, frankly the general climbing population has not proven themselves very reliable to check hardware before using it. I've seen many quicklinks which were unscrewed and then weight bend to the point where they won't thread back, 5/16" and 8mm included. I've also seen dozens of links which were so worn from grinding on the hanger that they had lost most of their integrity, this is not much of a problem on glue-ins, but definitely a reason to upsize your links on plate hangers (especially fixe ones which tend to have a sharper edge.) Anecdotally, the grinding effect seems to occur more slowly on SS links vs plated. The same friend who conducted the testing on trees had an instance where a screwed down 1/2" quicklink failed at ~800lbs while he was doing a pull test, the 1/2" quicklink was NOT what was supposed to be tested. It was found that the threads were of poor quality, the ql was of unknown origin but likely a cheap hardware store link. |

|

|

Final post regarding this- The above pictured anchor set-up is: 1) Uncommon 2) Not actually redundant 3) Comparatively difficult to clip and unnecessarily complicated due to the opposed mussys 4) Being promoted and installed (?) by an anchor maintenance organization

It’s not beautiful Any comparative benefits this set-up offers are negligible This set-up shouldn’t be promoted and proliferated on high traffic routes Add a screw-link to the left chain, split up the mussys, and solve every above stated issue for perhaps $5 ~Wank on bros~ |

|

|

DrRockso RRG wrote: Thanks for the interesting data about tree strength. And, wow, that's a scary story about that quicklink! We should all be buying quicklinks from reputable brands. |

|

|

Past User wrote: just a little nitpick on this (based on an epiphany moment i've had myself and surely others have had also), make sure that all your pieces below the bolt add up to an even number. while that left chain is long enough to pretty much completely take care of the problem, a shorter chain will squeeze the rope against the rock/twist it (ie that left bottom ring's natural orientation is parallel to the rock, not perpendicular [the way it should be]). |

|

|

old5ten wrote: Funny timing-- my partner and I were just discussing this issue while installing a vertically offset anchor to a shared ring today. While we did use an even number of pieces (and always do when possible), it was a spot where the size of the chain link from the upper anchor bolt were just big enough to make the lower bolt be weighted more than the upper, and we wanted to get them as evenly weighted as possible (the bolts had to be where they were in relation to each other due to the rock surface, etc.). We were carrying different sizes of QLs, so we were able to solve the problem with a slightly shorter QL (which we knew about before installing the bolts; this wasn't fixing an unanticipated mistake so much as using the opportunity to discuss a variety of potential solutions). but it got us talking about whether you could simply remove a chain link instead. The answer is yes, of course, though it would lead to the chain meeting the ring with a twist due to the odd number of links in the upper system. We noted that the length of the chain-and-QLs from the upper bolt in this case would likely be sufficient to overcome the twisting, but that when it can be avoided, it probably should be anyway (especially with the two anchor chains coming together on one ring). This anchor happens to be the first at a potential new spot, with several other viable routes being likely. However, for now we're keeping the hardware minimal; hence the single rap ring at the top of a single pitch. If the other routes pan out and the spot becomes a Spot, we plan to replace the ring with hooks. :) |

|

|

Past User wrote: It's not how I'd do it but there is nothing wrong with this anchor. Don't let perfection be the enemy of the good. |

|

|

Couple Horns n' Biner set ups. |

|

|

Give me fresh bolts and 2 clippable steel lower offs and I am not going to complain about 99.9% of the ways which they can be configured. System must: - not twist rope - must not twist the rope - must not twist the fucking rope Clean it however you want. Climb on it however you want. Replace shit, donate. All of this hardware is so damn beautiful - it has come so far from the days of rusty sharp hangers with no links, spaced horizontally 2 feet apart. With two clippable points, and the option to back it up… c’mon |

|

|

qq: why is it less desirable to have horizontally spaced anchors with opposite & opposed permas? Is it simply due to cost and marginally less visual impact of having one less (or shorter) dangly thing at one of the bolts? Since it is pretty standard to lead a route and leave two opposite & opposed draws at horizontally spaced anchors for brief lapping/top rope burns, I figured anchors with similarly oriented permas would also be widely accepted. old5ten wrote: Is this pinching against the rock really a problem? I've never noticed this happen on countless laps off two draws. Why would this happen with shorter chains more than long ones? I'd imagine the angle of the rock below the bolt would be the only contributing factor. |

|

|

|

|

|

james james wrote: Regarding the first question, James, yes: the cost of materials and reduction of unnecessary elements in the system are two reasons to use an offset configuration where a horizontal one could be used. It can get the same job done with fewer parts, which is good for your wallet and is just generally tidier and more elegant problem-solving (some would argue that reducing the number of links in the anchor system is also inherently safer, though when we're talking about high-quality quicklinks, chains, and hooks, often the strength of each component so far exceeds the need and the likelihood of failure of each is so remote that this point may be more academic than practical). Another reason to create the offset anchors that weight a primary point with a backup point is to reduce the number of consumable parts that need replacing down the line. In those anchors pictured above with the rams horn on top and a captive-eye carabiner down below, the rams horn is the single part that will wear out eventually from rope friction; assuming the bolts themselves remain solid, you may never have to replace the carabiner. (read: your local LCO may never have to replace the carabiner; we should all remember we are "gifting" our routes to the community, but that means it often becomes their responsibility to deal with the costs and labor of maintenance after that; even if I take a lot of personal responsibility for my routes and try to upgrade/replace hardware on them myself, eventually I am going to die, and people may still be climbing on my anchors.) All that said, horizontally spaced anchors are also fine in most places, assuming good rock. Really, we should be ready to use either/both configurations in most any spot. The often rock dictates which one will fit best in a particular spot, or which is going to be safest/longest-lasting. I actually use a horizontal configuration frequently, with both anchor points being equally weighted. If people are likely to toprope directly through the anchors or frequently pull the rope through in a high-grit environment, then I would be risking the wearing out of two elements instead of one, but plenty of places have local habits well established for TRing through your own gear only, or are places where rappel ropes can be retrieved cleanly and easily, etc. I will admit that sometimes my choice has to do with how many hooks or rap rings I have left in my supplies. I would never skimp on safety due to cost alone, of course, but I tend to think most carefully about conserving hardware when I am starting to run out and don't have the scratch to buy more yet, ha ha. Regarding the second question, the rope pinching against the rock is not always a problem, but it sure can be. In the picture that started this discussion, it looks like the pinching created by the righthand anchor point might not be too bad. However, for any anchor, if the rope runs hard over the rock immediately below the anchor, or if the rope were fat relative to the size of the links it were being threaded through for a lower/rappel, then you could get a lot more friction against the rock (harder to pull, maybe even grooves in the rock over time if it were a soft type [which it isn't in this case]) and twisting of the rope. Again, no absolute rules, but certainly factors to consider in each specific situation. If one can avoid the potential for twisting, it's probably worth it. It can happen more with shorter chains than longer ones because the links bind up against each other once they are rotated enough, and a long chain allows each link to rotate a bit without binding against its neighbors, while a short chain means each link has to twist further for the whole thing to rotate 90 degrees, so more chance that the binding will fight against the twisting. Likely the reason that you have not seen this phenomenon with draws is that the fabric of the dogbone can twist evenly along its entire length-- no binding. This allows a dogbone to twist further without as much resistance to that twist than a chain of the same length. If you were asking about metal permadraws at the anchor points, like with cable dogbones, I haven't done that. I imagine the cable dogbones would twist a bit better than chain without resisting, but they would still resist more than fabric dogbones. |

|

|

Scott Biegert wrote: Don’t you think that yellow cord looks a little sketch? |

|

|

Ackley The Improved wrote: Definitely an anchor your don’t want to shock load |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook