z4 trigger wire repair - how to remove old trigger wires?

|

|

As an update, none of the materials mentioned upthread have held up over time on my .75 Z4. Here is my latest attempt: 20 gauge galvanized steel wire. 20 gauge is exactly the biggest wire that will fit through the z4 and ul c4 trigger wire holes. EDIT: the 20ga wire also broke immediately |

|

|

Ellen Swrote: Did you try the welding wire? It's much stiffer and doesn't get all wavy and bendy like galvanized does. I've had no issues with the 4 cams I've repaired this way, in use for over a year now. |

|

|

Alex, Any ideas on capping off the ends of the short bends that terminate the wire and hold it on the lobe? I repaired a UL C4 #4 and sometimes the little "hooks" catch on slings and stuff. It's not really a problem per se, just kind of annoying. I wish I could make the ends a little fatter, like it was from the factory, but that would likely involve heating it and then somehow directly applying a lot of force. Maybe a little dob of sugru? Luckily, all my Z4's have been trouble free for the last few years, but I'm sure I'll eventually need to repair one. I like the lack of a swage, keeps things simple. Do you think the welding cable is stronger than the original wires? |

|

|

The folded over end needs to be able to pivot within the lobe, so a drop of glue won't work. The welding wire probably has a lower tensile strength than the stock cables, but it doesn't have the stress concentration at the crimp that causes the braided cable to break, so the welding wire likely will last longer overall. |

|

|

Scott Dwrote: I don't know what type of wire it was (it could have been something as low tech as the wire handle from a Chinese food take-out container. I've used that for C4 repairs), but if you clamp it in a vise so only 1/8 inch sticks up, heat that bit red hot and simultaneously keep tapping it with a hammer, you can get a nice little flare on the end. It does take practice. |

|

|

I’ve replaced a bootied .75s trigger wires with galvanized steel wire. Has held up supper good enough so far. |

|

|

looks like this is the closest thing to bd wire that i've come across. wire rope |

|

|

|

|

|

Phish Wwrote: Just did the same with my Z4s. After doing some research, dont see the need to replace the cable with the wire/cable combo. Wire seems totally solid and easily field replaceable. Galvanized wire is super cheap and fairly easy to do. |

|

|

I've been having the hardest time getting the cable out of the inside lobe on my Z4 0.2 that I broke the trigger wire on. I'm not totally convinced it's possible at this point. I wish I'd read this thread prior to going to work on it. Sounds like the swaging thing would have been the way to go, but it may be that I did this: Austin Donisanwrote: But it's more that I think there isn't enough room to maneuver it out with the small lobes on the 0.2. All the pics and convo in this thread seem to be of the larger Z4s. Gunkiemike, Alex, anyone else: have you had success removing the wire from the inner lobe of the single axle Z4s? It seems to me that the hole is not fully uncovered at any point in the range of travel of the lobes. Thanks in advance! |

|

|

Slim Pickenswrote: I've done a few of my Z4's at this point all with just a basic leatherman. The inside lobes are tricky. Cut the braided cable and then bend the wire straight-ish so you can shove the peen'd end out of the hole and cut it off. It's a bit fiddly for sure but definitely doable. |

|

|

Ellen Swrote: If you still need this fixed, I'm in town, will do it for free. I posted here about this a couple weeks ago with photos if you want to see. |

|

|

I bought the stuff that Adam Pecan posted and got to work trying to fix the frayed wires my 0.4/0.5 z4. I'm pretty good at fixing stuff but I've never quite done this before. On the whole it was fiddly and annoying, but I don't think there's a whole lot of technical skill required to do this and my final fix at least looks pretty close to factory. I got the old swages off by clamping them like clay with the swaging tool. The hard trigger wires are knurled at the bottom and it turns out you can smash them if you push hard enough. So I just clamped beside them (clamping similar to how you'd swage but with the flat section of the pliers) until they kinda oozed off like clay. There's probably a better way but this seemed safe compared to sidecuts. Putting the new swages on was pretty straightforward. I measured the size of the old cables (I got 6.3 mm from the flat of the trigger assembly to the bottom of the swage), added the extra for the cable inside the swage, and cut them in place. Actually clamping the swages at the correct angle with the cable and wire aligned all at once turned out to be incredibly annoying. It's not hard, but it's very fiddly and if you do it wrong there's not a great undo button (I did dremel one of them off after making this mistake). $45 delivered plus an hour of work. But I have enough cable to fix like a hundred of these. I'll report back in a year or earlier if it breaks before then. (Repost of Adam's in case it gets deleted). Cable - https://www.mcmaster.com/8930T53/ |

|

|

Brian- glad it worked out. If you make a mistake and need to redo the swage, I've found that just cutting the wire and smashing the swage with a hammer on a metal surface a few times will break it off quickly. |

|

|

I've had good luck using a pair of normal wire cutters to cut lengthwise along the factory swage so that the swage is cut, but not the solid wire inside. Don't take the solid wire out if you don't have to. |

|

|

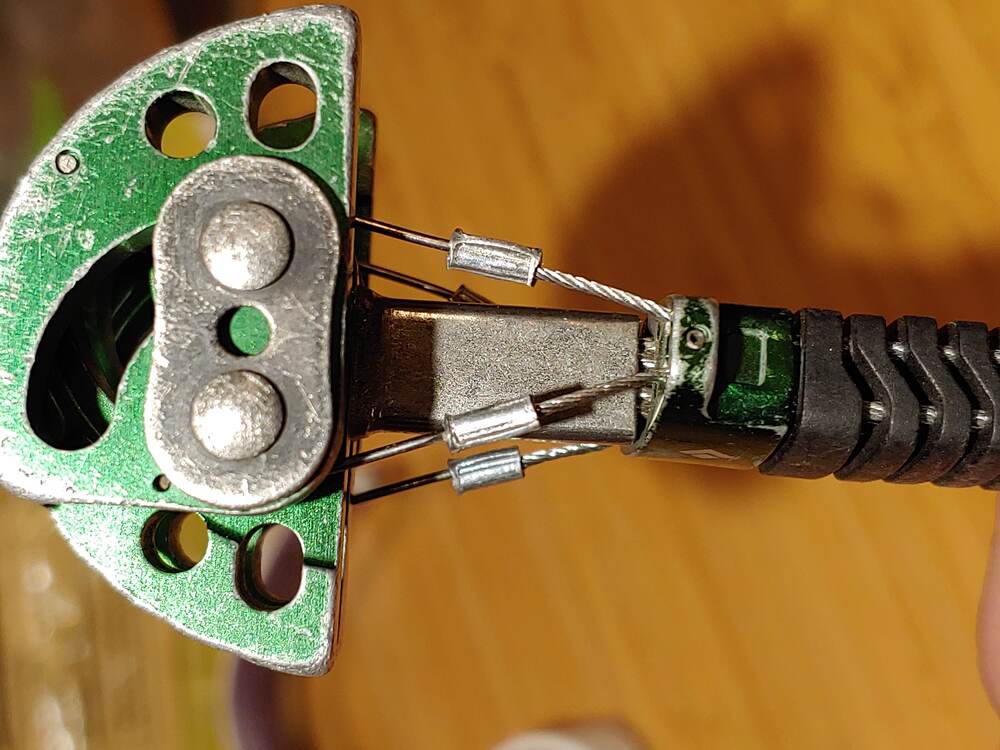

I took this challenge on recently because both my 0.75 trigger wires frayed right before going on a trip and I suspect it would take a month or more for BD to do the repair. Plus the full price including tax and shipping to repair just one cam was almost $35... and I only paid $60 for the cam new a few years ago. So I bought this kit on Amazon for $24 shipped that included a crimping tool and enough wire and ferrules to fix 25 cams. Seemed worth a shot, as all my other Z4s might fray too. What worked for me was using a very thin cutoff wheel on my dremel to carefully slice open the old ferrules without grinding into the rigid wire going to the lobe (which I reused), then prying it all the way off with small side cutters. After I got the method down this only took a couple minutes. The rigid lobe wires are already scored at the ends to give the crimp more friction, so I didn't modify them at all. I put the cable through the holes on the sleeve to make the V shape but left it long on one side. Lined up and crimped one end of the cable to the stiff lobe wire, then measured and cut the 2nd cable end with some sharp cutters to keep the end from splaying open. My tip is to slide the ferrule over the braided cable first then slide it down and back up to capture the stiff wire. Holding the ferrule at 45 deg allowed just enough room to get the crimper tool on there without modification. Took me maybe 90 min but half that was figuring out how to cut off the old ferrules. I could probably do both wires on another cam in 20 min now. So far so good but I'll report back if it fails prematurely. Here are my pics: album Before: After: |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook