Core drilling tools for bolt replacement

|

|

That's helpful! Thanks for posting. Is there a good glue-in that you put in a 16mm hole? |

|

|

bmdhacks wrote: 8mm twist bolt, the best glue in! |

|

|

Jim Day wrote: Does anyone have more information on the inside diameter of the larger bits? Im looking for a bit to remove some 14mm single leg glue ins. Seems like its generally ~3-4mm increase from ID to OD. You think Id be safe with an 18mm bit to remove a 14mm bolt? Would there be a better adapter system for larger diameters / longer bolts? |

|

|

Alec Baker wrote: I got a couple of the 17mm to remove botched glue ins. The ID is 14.7mm which should work for you, and leaves a hole that will fit the 8mm twist bolts. They only have a ~92mm drilling depth which isn’t enough for wave bolts, or many other glue ins. Possible longer ones are available, but I haven’t looked. |

|

|

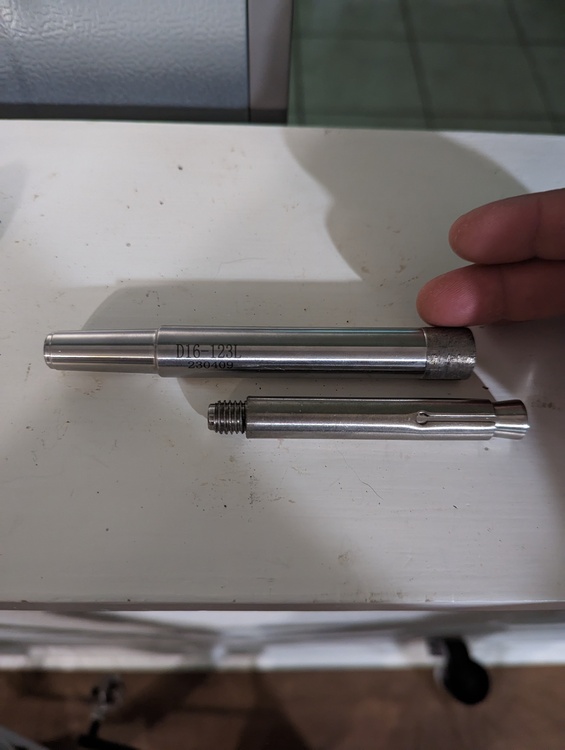

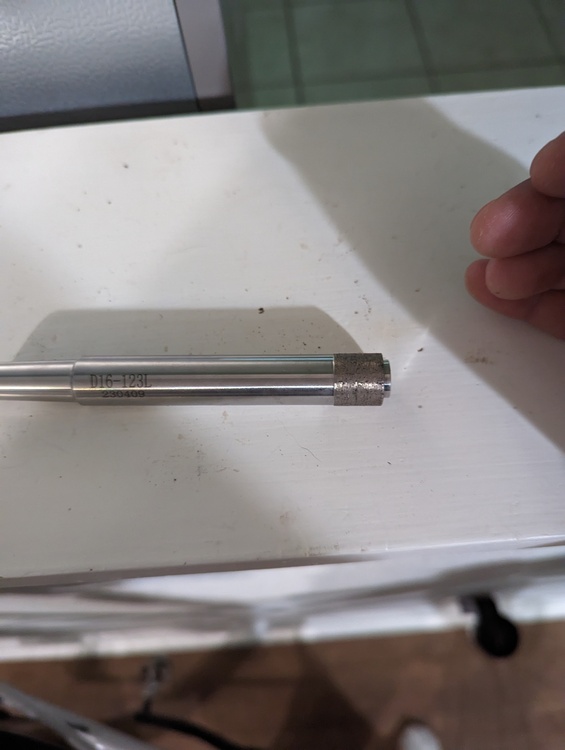

Every bit I've bought (12, 13, 15, and 16) has had a thick spot on the ID. This is a picture of the D16, which has a 12mm ID on the narrowest portion but 13mm everywhere else. It fits a 1/2" wedge bolt (up to the clip) and 12mm sleeves, but the 1/2" powers sleeves I could tell it was tight and I only went half an inch over the sleeve, I had to funk out at that point. I'll probably plan on 17mm bits for 1/2" sleeves in the future. |

|

|

Thanks Peter and Jim, very helpful! |

|

|

Peter Thomas wrote: Aliexpress has 17mm 153mm length bits (105mm core depth) available through the Ali app. They are just long enough to get the shank depth of a wave bolt. |

|

|

I think that even if you have a centimeter or two embedded glue depth left after core drilling 92mm, you could mangle/leverage out a wave or twist bolt with a nail puller pretty easily. I once leveraged out a 100mm twist bolt that was only installed halfway before the A7 glue set, it took 15-20 minutes with a nail puller |

|

|

Jim Day wrote: Im confused how youd core drill a glue in, but still have the eye to pry out? |

|

|

Alec Baker wrote: Good point :P I would try to cut off the eye with a hacksaw, core drill, then wiggle the stubs out with vice grips. I haven't had to try yet, but am interested on other suggestions |

|

|

Lol no worries, just wanted to make sure I wasnt missing something obvious |

|

|

I managed to core drill a twist bolt. Im sure with practice it would get easier, but this took me 2L of water and over an hour. |

|

|

Red neck core drilling plus Hurley Sr. Style pulling tool has been used in the past for Wave bolts. I wonder if that can be a standard method for most glue ins? I have one of these new style thin wall core drilling rigs but find that Red neck core drilling gets the job done. Only requires a few small diameter bits beyond the standard tools required. Consequenty the thin wall core drill has only been tested in the garage. I have not been removing glue-ins though. |

|

|

I've read about using "redneck" core drilling on wave bolts, but I haven't read anything about doing that with twist bolts. After using the thin wall core drill bit as deep as it would go, I still needed to use the "redneck" core drill method to get the last bit of epoxy to disengage, but I could do that without widening the entry hole and I was able to pull out the rest of the bolt with needle nose vice grips. |

|

|

Alec Baker wrote: Did you use D16 or D17 bit? |

|

|

D16. It bound up quite a bit but i think that was mostly poor drilling on my part |

|

|

For those of you that have bought these in different sizes, which size outer diameter would I have to buy to remove 10mm wedge bolts? Any info is appreciated. |

|

|

The 13 should work for you. It might just skim the outside of M10 bolts |

|

|

10mm bolt info I found online calls for a 12mm hole. The extra 2mm is for sleeve expansion. 15mm bit has an internal diameter of 12.27 (ish). |

|

|

Brian Murphey wrote: I'm not sure where you read that but most 10mm wedge bolts require a 10mm hole. D13 will be best for 10mm wedge bolts. I have a 10mm threaded rod and it slides right in to a D13: |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook