Deburring and Rethread tools

|

|

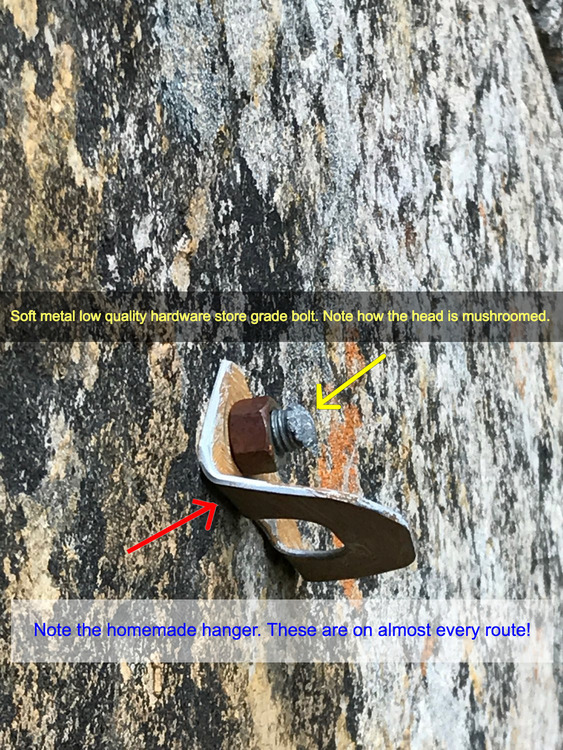

Hey fellas, Been following this tread for a long time and have rebolted countless climbs at this point with the advice found on here so thanks. Recently I have ran into some problems with old 3/8ths bolts with poor metal and installation from back in the 90s? The threads are are in all states of dismay mostly the bolt ends being mushroomed. Wondering if you have ran into this much and what deburring tool you have been successful with. I am looking for both one to attach to a drill and a hand operated one for wilderness areas. I have messed up 2 spinner attachments and 1 cheaper deburring attachment and 1 rethread nut. Cheers, Jake |

|

|

Hi Jake, There are quite a few cheap deburring tools, but I’ve not found them to work very well. I ended up getting one of these that fits on a spinner tool. It’s expensive but works quite well. It would not work well/at all by hand. A plain file will work, but can be a little tedious. https://www.mcmaster.com/product/3500N23 I generally carry both 5/16 and 3/8 dies for repairing threads on bolts or on drawstuds. I’ve found with those cheap is good since the dirt and rust messes them up. What are you using for your couplers in spinner adapters? Those make a big difference. If you PM me with your address, I will send you a couple I make that I think are the best available. Im currently on the road and won’t be able to get them out for a couple weeks. I’ve found that most bolts with really mushroomed heads are split shafts or some other non standard bolt (there’s no reason to hit a wedge bolt that hard) in which case they won’t spin, and if you try hard at spinning will break. |

|

|

Thanks, Peter. I might give that pipe mill a try. It seems beefier and much more convenient, especially if it fits onto an SDS chuck. As for spinner adapters, I’ve made my own a few times now. I used a coupler nut that fits onto my SDS chuck with a 3/8 double-thread insert with some red Loctite. I’ll send you a DM and would be happy to test out your version if it’s any different. I’ll also attach a picture of the bolts I’m dealing with. The one pictured is not terrible compared to others I have seen. They’re not split shafts, just low-quality wedge bolts from the 90s. I’ve had no issues spinning them in granite (the granite is not super bullet) when the threads are intact, but the ones I’ve found in basalt areas have been much tougher on my spinner tool. If it comes down to it, I may have to core drill. There are hundreds of these bolts in the area, and without support from any organization, the time and cost to replace them with glue-ins, especially in a lower-traffic area with no corrosion risk, would be substantial. |

|

|

Can you back off the nut holding the hanger on, or does that get stuck at the mushroom? I've had luck with a small hand file to debur and a 3/8" die to refresh threads. I also got a low profile nut to thread on when I hit the bolt to disengage the clip so that I can back it off to fix any mushrooming I added with my hammer. |

|

|

bmdhacks wrote: I can back it off a bit, but it won't clear the mushrooming. I tried filing it for about 20 minutes before getting frustrated and stopping. I’m confident that if I kept at it, I could eventually succeed, but I’m looking for a faster method since there are so many of these bolts. The picture above is just one example of the wide range of old bolt conditions in this area. For some bolts, the threads are fine; others are severely mushroomed. In some cases, I just used an angle grinder, patched the hole, and drilled a new one. But there have been instances where the bolts are mushroomed like the one pictured, and because of the placement and the rock condition, I need to reuse the same hole. ***Side note*** Has anyone out there had experience replacing bolts in wilderness areas? How many of you are spinning the bolts and using a YABR, or are you just using a breaker bar to break them off and hand-drilling a new hole? Have you ever used a YABR to snap a bolt? I’m specifically working with 5/16 and 3/8-inch bolts. I also have a old tuning fork made from a old lost arrow for removing old split-shaft/ drive-ins. Maybe this should be a different thread. |

|

|

I highly recommend the core drilling techniques in this thread ( mountainproject.com/forum/t…) We have found them to have a higher success rate and take much less time that the spin and pull method |

|

|

I aim for 100% reusing the hole, but have done almost no rebolting in wilderness. The YABR is not a good tool for snapping bolts off if you go that route. It would be far more efficient to just screw the nut until the bolt breaks. What kind of rock are you working in? I have had pretty good success pulling bolts without spinning in soft rocks. Since it sounds like you’re carrying a hacksaw, anyway you could cut the bolt stud flesh with the nut to eliminate the mushroom then back the nut off, and you should have clean threads for spinning and pulling The core drill method mentioned above is a great back up. It is not my preference for reasons I talk about in that thread, but when a bolt breaks, it’s awesome to be able to salvage the hole. This is another tech that probably would not help in wilderness. |

|

|

Peter Thomas wrote: On the same page with using the same hole for every reason especially how much work drilling a new hole is with a hand drill. It is in granite. Castle crags to be more specific. Which has multiple generations of different shitty hardware. Yup, the hacksaw works but like everything else it’s super exhaustive. Maybe I will try the hand spinner thing I watched a video of it once. Though for the 3/8th bolts I am not sure what it takes to hand drill a 1/2” hole. Funny to be replacing bolts with a hand drill that were most likely placed with a powerdrill. |

|

|

I have had success using the Pasco Tiny Tim hack saw to cut off the mushroom head and then using a fine file to deburr the stud before attempting to remove the nut. |

|

|

There is such a thing as a thread file specially made for restoring threads, everybody needs one (once)! |

|

|

I haven't tried this yet, but it's worth a shot- there are lots of these chunky diamond grit core bits that won't work well for removing bolts, but might work for deburring. The 12mm OD version looks like it has an ID less than 10mm. Not sure how your drill setup would work to chuck it, but it looks like it could be used to completely grind off the exterior threads for the first ~1/4" of the bolt. The problem with most of the external chamfer tools is the width of the tool and the required length of the bolt to be deburred. This would get around that problem. |

|

|

Jake, Your doing good work. Contact Greg Barnes with the ASCA. He will most likely be able to help out your cause, as he has for hundreds(thousands?) of reboltiing fiends like yourself

Thanks for your service! |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook