Patagonia Grade VII ... It's Back!

|

|

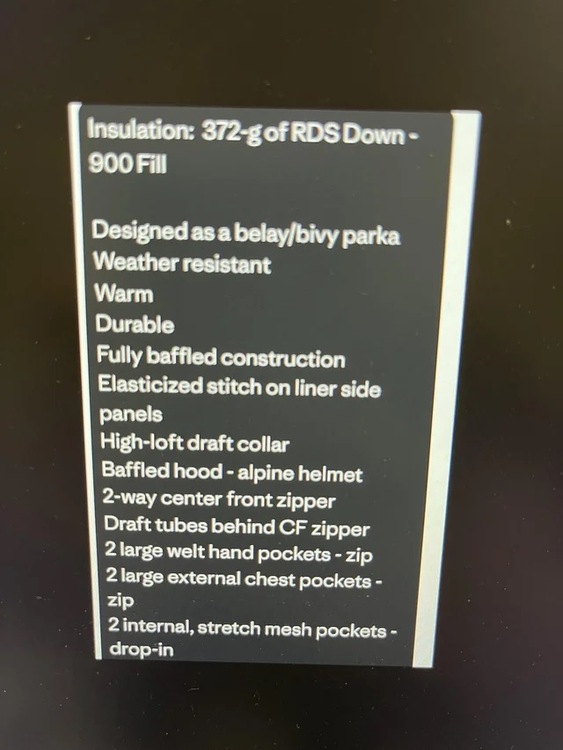

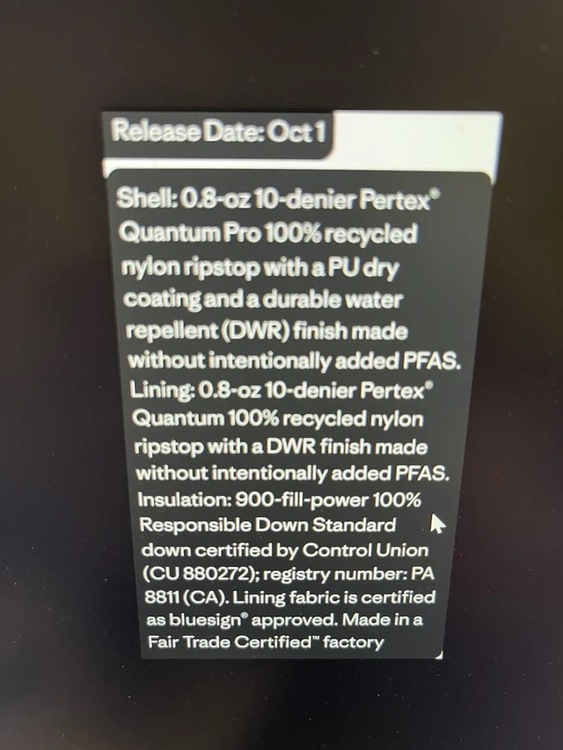

- 372 grams of 900-fill. (No size given, but likely in a medium.) - No overall jacket weight provided yet. - October 1, 2025 release. -10D face fabric.

|

|

|

Looks nice. I bet they will probably be around $1000. lol |

|

|

some chatter about it on the patagonia subreddit, price should be $999 so quite pricy, 712g weight for unknown size |

|

|

Seems like a pretty poor option compared to mountain equipments offerings. |

|

|

that guy named sebwrote: Ehhh, not sure I'd agree. Though I love ME's belay jacket line up, owning a Xeros and Citadel, they're not making anything close to matching 372g of 900-fill at an overall jacket weight of ~712 grams. I'm not saying the new Grade VII is the end all, be all, but comparing ME's line up isn't apples to apples here, IMHO. |

|

|

The k7 would be closest, 300g of 800fillpower down, it has the crucial drop shell which dramatically improves it's warmth and protection. Not quite as light as the patagucci however and the cuffs on the patagonia are nicer. |

|

|

It’s officially back. https://www.patagonia.com/products/grade-vii-down-belay-parka/84847.html I managed to get one early and it came in lighter than the listed weight for a medium. |

|

|

that guy named sebwrote: 372x900=334800 300x800=240000 The new GVIII has 1.4x the loft of the K7– they’re barely in the same segment. |

|

|

Eli Wwrote: It's just not that simple. |

|

|

that guy named sebwrote: Tell us more Seb. I'm realizing I don't know much about how fill power, fill quality, construction/baffle arrangement, etc combine to make a warm piece of gear. |

|

|

Andy Shoemakerwrote: Well, there's a lot of little details, things like fill density in baffles, variable fill density in areas like elbows where down moves around a lot, baffle design, cuff design, hood design, drop shells,hem design, and fit, all these factors will have an impact and cumulatively have a huge effect on the warmth of a jacket. This you know. But there is also what we don't know, does increase in fill power result in a linear increase in warmth? Is 1000 fill power down twice as warm as 500 fill power down? Or is the increase in loft volume the result of different structural properties of the down cluster? We don't know. How do different fill powers respond differently to different levels of humidity? I have heard mixed things from people in industry and it hasn't been properly tested in any scientific literature I've looked at. Optimal fill density for down even has conflicting information, I have seen two papers draw entirely opposite conclusions from similar testing. There is also the fact that fill power is testing volume and not insulating properties. The actual test procedure may be essentially hacked by stiffening the down filaments to prevent collapse, this was done by patagonia years ago with plasma treated down, there is no guarantee however that this higher volume actually led to higher insulation. Basically, while higher fill power down can be considered warmer than low fill power down all else being equal, we don't know when/if there are diminishing returns. So with the many technical unknowns and the numerous other factors that can impact the warmth of a garment, It doesn't make sense to draw any significant conclusions from fill power, especially when they're close. Consider this, for all we know, fill power may be a marketing term with limited practical impact. And let's not even get into how layering can effect all this and how increased volume may result in dew points forming within insulation. |

|

|

for down jackets, the tldr is higher fill power=somewhat warmer, mainly lighter+higher quality. a down jacket with 50g of down is never going to be close to a parka with 200g even with box baffles and other better design aspects, for similar jackets the better features+design will provide a better experience and overall higher quality jacket this spreadsheet looks more at UL jackets but you can see how different jackets stack up comparing different specs down jacket spreadsheet this review of the previous grade vii also highlights how the smaller features create a better parka than other similar jackets and why grade vii review |

|

|

Something I think isn't considered enough is also the level of care one puts into maintaining their down. 900-1000 fp down is fine enough that it's ability to maintain volume (insulating value for short) is much more heavily affected by dirt and body oils compared to 600-800 fp down that has more robust clusters. If you're actually using your down gear on a regular basis and aren't cleaning/keeping it clean religiously, I think there's little sense in going past 800 or 850 since the warmth-weight benefit of super premium down is negated quite quickly with dirt and oil accumulation on normal use. |

|

|

that guy named sebwrote: Great response, especially with elbow / arm coverage. That's one of the worst parts about down insulation - the inevitable down migration in high-movement areas. Inner arms & elbows are extremely difficult to properly baffle and ME always seems to nail it, likely thanks to "Dr. Down" and their Firestorm baffling technology. Also, very well said in terms of humidity with higher fill-power down. The higher the fill-power, the more fragile the cluster, which, in turn, the more susceptible the down is to any form of moisture. Another debated topic is the application of water-resistant chemicals to natural down. Some argue it's a game changer and some argue it hinders loft and longevity. As far as I know, no real science to back either side definitively, though I've never noticed loft hinderance in any of my treated belay jackets. If only there was a way to incase the down within a waterproof baffle from both the inside and outside, protecting it from interior body vapor, melting snow and also outside moisture. |

|

|

A fool and their money… How dumb do you have to be to pay $1K for belay jacket? |

|

|

Here’s an even more expensive offering from The North Face, curious what the materials scientists think of it. |

|

|

bearded samwrote: That down is really cool, it uses gold nano particles as a catalyst to speed up dry times, I got to talk to the CEO of allied feather and down (the main supplier for pretty much all outdoor brands) and they were working on this about 5 years ago, very cool stuff. The ripstop is good because lightweight fabrics have practically no tear resistance but spectre isn't the best option as the fibre is likely to rip out and mess up the fabric before it can ever break. I like the baffling, the less stitching the better. |

|

|

that guy named sebwrote: I've been skeptical of the dry down treatments ever since the Patagonia debacle with their "encapsil" water resistant down. Their encapsil water resistant down parka cost a fortune, but the down inevitably clumped up and created huge cold spots throughout the entire parka. It was completely useless. I was really surprised they actually released it to the public. Since then, I've just gone back to high-quality European goose down (Valandre, PHD, and Cumulus) and have been very happy with the results. The tests that this guy ran using wet down are illuminating: |

|

|

Kai Larsonwrote: That guy sucks sorry to say, his testing on the surface looks impressive but falls down when you say, what about humidity? What if I get my hood full of snow at a winter belay? What if I'm in a cloud and I am surrounded by liquid water? Down is pretty water resistant, more so than wool, but the tests he uses don't really represent the real concerns and pointing at a demonstrator used by various companies to show their down is hydrophobic isn't really compelling as an argument against BIG DOWN. These tests also neglect to think about the actual outcomes. If your bag is say 10% less insulating after day 4, you get into your tent cold and tired, you'll be that little bit colder through the night and that bit more uncomfortable. The encapsil stuff was also a totally different ball game being plasma treated instead of a silicon or some other PFAS alternative. And to clarify, while TNF down jacket is using dry down the gold catalyst is measurably better. Everest was summited wearing a cotton outer jacket and big leather boots, lots of Scottish winter routes were put up wearing tweed. Everything we put out today is mostly just about improving comfort, it's very rare that kit these days isn't up to the job. |

|

|

that guy named sebwrote: Not sure why he "sucks." I've spent some nights in wet down sleeping bags. Not ideal, but not the death trap that some folks think it is. My personal experiences pretty much track his results. For any situation that is cold enough that a massive belay parka is required, the chances of driving rain is generally pretty low. Same with sleeping bags; the colder it gets, the less likely you are going to encounter wet conditions. I generally winter camp in a floorless pyramid tent. Single wall, lots of condensation/frost on the tent walls. Never had an issue with my down bag getting wet enough to notice, even on multi-day trips. Maybe if I was living in a snow hole in Scotland or Patagonia for weeks at a time it would be an issue. However, in those conditions, I'd rather just go synthetic. Dry treated down makes more sense in warmer conditions, where the temps are 30 degrees or higher, for both jackets and sleeping bags. However, at those temps, you are not using a ton of iinsulation, so the type of fill you are using has less of an effect on weight and bulk. Might as well just use a synthetic like the Nano-Puff in those conditions. |

|

|

Kai, I have lay in a snow hole with a soden down parka that was doing nothing and I was dieing of hypothermia(this isn't hyperbole). While your experience may tell you hydrophobic down isn't necessary I really wished my down was hydrophobic at that time(honestly at the time I was wishing I was in a synthetic jacket). This was summer on Mont Blanc, the weather was 12c warmer than it was forecast and we were stuck in a whiteout, in a cloud. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook