Ultralight Hand Drills?

|

|

I have a vague memory of seeing some custom UL, low profile hand drills out there but can't seem to find mention of them anywhere. I also remember mention of wrapping tape around a drill bit as a makeshift handle, has anyone actually done this? The use-case would be for big remote alpine mixed walls. Hopefully we never have to pull it out, so weight and size is almost more important than function. |

|

|

The tape thing is terrible, but passable for on rappel/bail. Workable with a very good stance |

|

|

Yes, I actually have wrapped duck tape around a drill, for a handle. US made hss drill, short flutes, longish shank, with a straight chisel point ground on the tip. It does work. I don't know how modern imported drills would hold up. |

|

|

|

|

|

Kristoffer Wickstrom wrote: Exactly what I had in mind. Did you make this one? |

|

|

|

|

|

Michael T wrote: Yes, that particular one was destroyed in testing. Wrong temper on the O-1 steel striking surface. |

|

|

fixe has a compact, lightweight hand drill https://fixehardware.com/index.php/fixehardware-hand-drill.html ultimately, if this is for emergency situations (just a bolt or two) then going with just a bit will be your lightest and most compact choice. it’s by no means the most comfortable or easiest way to drill but it can be done. actually happens quite a bit when your battery dies halfway through drilling a hole and you “have” to get it done) if you’re going backcountry/light/emergency it might also be worth to look into/consider non-standard bolt options (eg shorter 1/4” ). the big downsides are strength, safety, longevity (relative to something more standard like a 3/8” wedge or sleeve) |

|

|

old5ten wrote: Yeah we’re planning on using 1/4” rivets. It’s a last resort option on a face that more likely than not won’t see a repeat. I ended up ordering one of the short Dammerr holders since I could get some use out of it beyond this particular climb. |

|

|

old5ten wrote: Have you actually drilled a hole with just a bit? I’ve finished a few holes with just the bit when the battery died. I found it unbelievably unbelievably ineffective, even with the hole already established. Just curious if the bit only is theory or practice. |

|

|

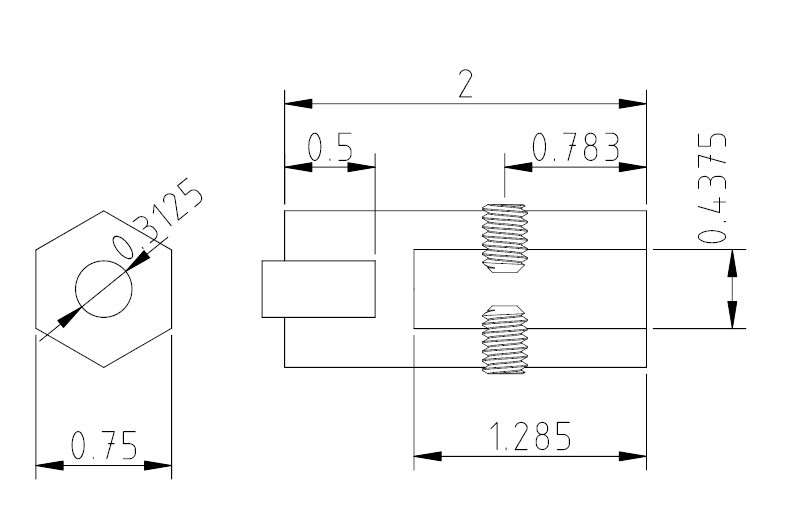

I have tried to drill with a bare SDS bit and it was painful. With just the bit it is impossible to apply much torque so it gets stuck easily. You need to have something to absorb the shock and something to apply some torque. The lightest holder that I've made is this one. I don't recall the weight but it wasn't much. I actually haven't tried to drill with one but others have (DeWeese?) and it is possible but probably not very comfortable. I could make some but I always encourage people to make their own gear if possible. It was made from a piece of 3/4" hex, a 5/16" hardened dowel pin and two set screws. The grip was cast from urethane. To make a simpler one I would skip the lanyard loop and make the grip from Versimold. Versimold is a stiff rubbery goop that can be formed into any shape and then baked at 200 degrees F to make its shape permanent. The drill holder that I use has a Versimold grip and it is actually better than the urethane but ugly. If anybody wants to try to make their own, I'd be happy to consult. |

|

|

|

|

|

ROC- pec is 7oz |

|

|

The tape around the drill bit eventually just twists cause the glue gets hot and melts from the hammering. Maybe climbing tape is better idk |

|

|

I might have to order one of those Fixe holders, it looks like they may have copied a couple of my ideas. Thanks Fail Falling I appreciate you chiming in. |

|

|

I've used the bit a few times when battery ran out. Passable enough in sandstone. When do you need it by? I just had an idea for a simple home made UL design. Start with 1" diameter aluminum round stock. Drill pilot hole (5/16") all the way through. Then from back side. Drill a hole with a bit 1/16" larger than SDS chuck most of the way through. Slide bit in and measure so length is 15/16" longer than end of bit. Drill and tap for 7/16 bolt from back side. Make sure threads go more than one in in. But a grade 8 7/16" bolt that is 1" long (tap bolt with full threads). That is your anvil and bit keeper. You could also side bolt to leave room for a key ring, then Paracord attachment. Then drill a bunch of holes in side wall of bit holder for weight reduction. Chamfering the holes will provide texture for torque. You should be able to do everything with a drill press. Tip: for the initial pilot hole, drill from both sides halfway slightly smaller, then follow through with the correct size all the way). |

|

|

Rprops wrote: yep, over the decades i've done my fair share of drilling with just a bit (last was two holes on a new route in cochise a couple of years ago). mostly 3/8" in granite when the battery died and a few times where i didn't want to take a handle for weight reasons. as i mentioned previously, it's not the most comfortable or easiest way to go. ultimately, it (as in most cases) is a matter of priorities. in this case there was an emphasis on weight savings and emergency use. add to that 1/4" and really short bolts and the bit only option becomes even more appealing... |

|

|

Just to see how it turned out, I made an aluminum and steel holder. The steel core is about half the length of the holder and threads into the aluminum grip. The steel is glued in with red Loctite. I've made similar ones in the past but I tried to lighten this one up by moving the leash attachment. I like having the leash at the bottom where it is in your hand which makes sure it rotates. Since the aluminum is denser than the rubber, it didn't turn out particularly lightweight. |

|

|

Nice knurling on that aluminum Dan! |

|

|

Kristoffer Wickstrom wrote: My technique is mostly based on luck. |

|

|

Buddy of mine had a sawed off Rawl drive handle, at half length, and no rubber grip, just some tape. It was for back country work only. Jesus that thing sucked to use, smashed my knuckles more than once with that torture device. It worked though, albeit slowly. I've preferred a beefier hand kit ever since, rubber grip mandatory for this soft handed punter. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook