Looking for the detailed screw sharpening guide- FOUND .PDF DOWNLOAD

|

|

It's no longer in my book marks and all the search results are other folks looking for the same thing without resolution. Thanks! EDIT: Link to tool list (link to guide is dead on this page) : https://neice.com/xenforo/index.php?threads/ice-screw-sharpening-how-to-guide-and-service.623/ Download: https://docplayer.net/40342349-Ice-screw-sharpening-procedure.html |

|

|

Thanks for stickying this! |

|

|

Anyone know of a 3d printable jig? |

|

|

Jake, I recommend learning how to do it by hand. You'll need a bench mounted vice setup with soft jaws (two blocks of pine work too). It takes a some experience so perhaps you could use an old screw you don't care to use any more to practice on. Having a new(ish) screw that hasn't been sharpened to reference the angles helps a lot. I was able to get my hands on a very thin, flat cross-cute file that helps tremendously because it will remove material while moving the file in both directions. Single cut files only work in the forward direction. You will also need a very fine chainsaw file, 3mm I think, to get the throat cut properly. If the tips are badly damaged, I start by taking the fat bastard and file the teeth down to the same level before re-profiling the cutting edges. It cannot be stressed enough that when you level the teeth they need to be perpendicular to the length of the screw, otherwise the cutting tips will not engage at the same time resulting in a slower starts. You will probably need to order the correct files online, so order handles to go with them. It makes them easier to use. I also like to wear a pair of deerskin gloves (the yellow scarecrow gloves) that are common at hardware stores and garden centers. Just be sure to test the sharpness with your bare hands, taking care not to damage your skin. My primary concern with a printed jig would be filling away the polymer resulting in a poorly profiled cutting edge. If you can mitigate this issue and/or find printing documents please add any information or links you may find to this thread. Thanks for the interest, and good luck with your screws. |

|

|

If anyone wants a dead screw to practice on, I have a BD 16 that you can have for the cost of shipping plus one dollar. |

|

|

|

|

|

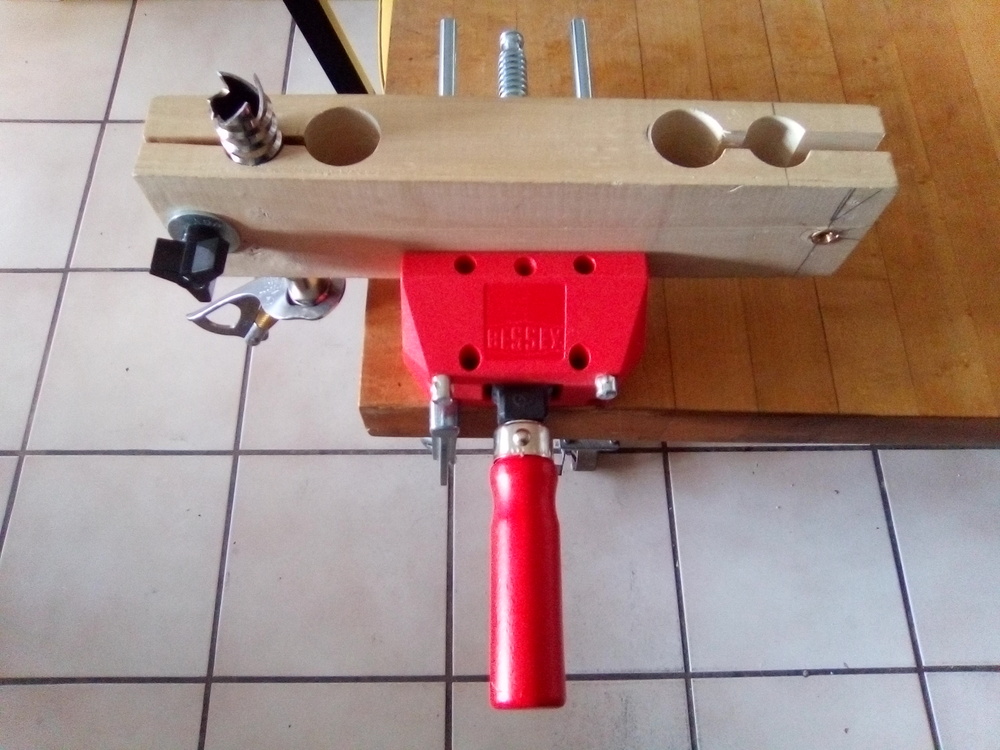

Paul Morrisonwrote: Excellent jig. The two blocks of wood I recommend are a huge pain in the ass Would you mind sharing what type of vice that is? |

|

|

Bessey S-10. You can take it on the road; it clamps to tables and counters. It will hold tools and crampons, too. And it's a vise. The right-hand hole is a little larger than the one on the left, for aluminum screws. The two inner holes are just there to facilitate bending the wood with the knob. |

|

|

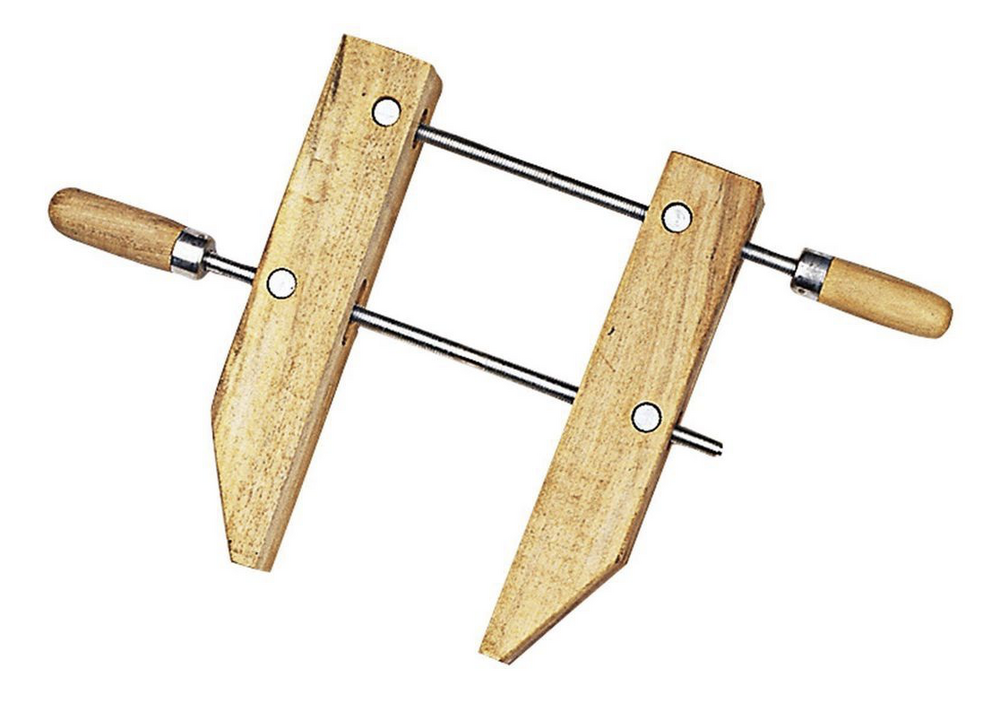

You could use a handscrew clamp, because the jaws can be set out of parallel. But you'd need another clamp to fix it to a surface. |

|

|

Paul Morrisonwrote: You could market this |

|

|

Rasputin NLNwrote: This is a great resource; thank you! |

|

|

Both links are dead. Anyone have an updated link? |

|

|

Nate Haebig-Kerberwrote: You can find the link to the first at Archive.org: https://web.archive.org/web/20210513145116/ neice.com/xenforo/index.php… but the link to the 2017 PDF is dead. Searching the name of the linked 2017 document, "Ice_Screw_Sharpening_Procedure_2017.pdf" on google, the first hit is this PDF from 2020: http://www.clideadv.com/Ice_Screw_Sharpening_Procedure_2020.pdf Which is a downloadable 10 page PDF on how to sharpen ice screws, including how to source/make your own blocks/jigs, and what tools to use. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook