|

|

FrankPS

·

Dec 20, 2024

·

Atascadero, CA

· Joined Nov 2009

· Points: 276

You could just drop it, Kyle, unless it's really important to be right and get the last word in.

|

|

|

Climbing Weasel

·

Dec 20, 2024

·

Massachusetts

· Joined May 2022

· Points: 0

Are your runners single strands with spliced eyes at either end, or essentially small closed slings covered in sheathing? The blue ice ones are the second option.

|

|

|

Jacob W

·

Dec 20, 2024

·

Richmond, VA

· Joined Jun 2023

· Points: 0

I say this whole thread gets dropped and continued through DMs if it’s felt to be necessary.

|

|

|

Micah Hoover

·

Dec 20, 2024

·

Seattle, WA

· Joined Oct 2016

· Points: 1

Oh boo, I'd happily see it go another 4 pages. This might be the thread of the year. He used "irrefutable betterness" in a sentence. Dyneema swami belt and a macreme tie in?

|

|

|

Jared E

·

Dec 21, 2024

·

CO-based healthcare traveler

· Joined Nov 2022

· Points: 417

Jacob Wwrote:I say this whole thread gets dropped and continued through DMs if it’s felt to be necessary. Overruled

|

|

|

Ben Zartman

·

Dec 21, 2024

·

Little Compton, RI

· Joined Apr 2024

· Points: 0

I, too, think this thread has run its course, and a little more. @Climbing Weasel: I have several different sorts,with different ratings. The Anchor Extender that is in hot debate is a Dyneema-cored rope with a polyester cover with an eye spliced in each end. It is UIAA and EN-rated to 9kN. I have also Seamless Runners, that are a closed loop of SK99 Dyneema core inside a Dyneema cover with an anti-UV coating. Those are UIAA and EN rated to 24kN. There are also quickdraw bodies, with an SK99 Dyneema core and a dyneema cover, which could be described as "dogbones." Also UIAA 24kN. Last in the catalog of UIAA-certified products are a the same core as the two last-listed slings, but with a Technora cover for autoblock and friction hitch use. 24kN on the long axis: no testing data when used as autoblock or hitch. @Kyle: you're right. I have wandered into an inconsistency in what I desire and what I do. I'm sorry I worked you over so hard about it; let's make peace. I'll say this in closing: there needs to be more testing. To that end, my offer of five Anchor Extenders to whomever will break test them on a machine that we can at least ghetto-calibrate by breaking something of known load rating first, and take our numbers from there. Sound fair? I'll even throw in a sample of shoulder-length runners and we can run them through the wringer as well.

|

|

|

FrankPS

·

Dec 21, 2024

·

Atascadero, CA

· Joined Nov 2009

· Points: 276

Ben Zartmanwrote:I, too, think this thread has run its course, and a little more. @Climbing Weasel: I have several different sorts,with different ratings. The Anchor Extender that is in hot debate is a Dyneema-cored rope with a polyester cover with an eye spliced in each end. It is UIAA and EN-rated to 9kN. I have also Seamless Runners, that are a closed loop of SK99 Dyneema core inside a Dyneema cover with an anti-UV coating. Those are UIAA and EN rated to 24kN. There are also quickdraw bodies, with an SK99 Dyneema core and a dyneema cover, which could be described as "dogbones." Also UIAA 24kN. Last in the catalog of UIAA-certified products are a the same core as the two last-listed slings, but with a Technora cover for autoblock and friction hitch use. 24kN on the long axis: no testing data when used as autoblock or hitch. @Kyle: you're right. I have wandered into an inconsistency in what I desire and what I do. I'm sorry I worked you over so hard about it; let's make peace. I'll say this in closing: there needs to be more testing. To that end, my offer of five Anchor Extenders to whomever will break test them on a machine that we can at least ghetto-calibrate by breaking something of known load rating first, and take our numbers from there. Sound fair? I'll even throw in a sample of shoulder-length runners and we can run them through the wringer as well. You agree this thread has run its course, then go on to lay down another half page on the subject?

|

|

|

Mr Rogers

·

Dec 21, 2024

·

Pollock Pines and Bay area CA

· Joined Aug 2010

· Points: 77

Kyle,

Thanks for fighting the good fight! lol.

I took a break from this thread as Ben Z. can not for the life of him be humbled.

He states multiple times my clearly superior products. Which is so based in ego its mind blowing, and part of the reason its hard to be constructive in discourse with him. HE IS RIGHT.

Dude is so in his own world, he doesn't realize major MFGs have made products that fill the holes in gear that he's attempting to fill....at 1/4 of the cost.

He ignores that there has been 1000's of tests using aramids and HMPE, and thinks that somehow sheathing some SK99 is going to change the reduction of 40% in those types of fibers when knotted. Hint, it will break in the knot with about 40% reduction in strength.

He ignores advice from people who might actually have more knowledge than him in some areas of rope craft.... Then he back handedly insults folks as basically being dumber than him for questioning him.

Claims above,In the world of rigging, a hitch is not a knot....as a rigger in the world this is not true, many of us know a hitch is a type of knot, saying go tie a clove hitch doesnt somehow mean you're not tying a type of knot. I don't get why he gets to be pedantic, but not Mark.

In the end so many claims he makes around superiority, IMO, means the onus of proof lies with him to back up those claims. I'm waiting for that moment, but get a lot of defensive hot air thus far.

I applaud this man in getting his products certified, thats not easy. I applaud his want to push rope craft into the next decade. But I do not applaud his bullheadedness.

Cést La Vié.

EDIT: To that end, my offer of five Anchor Extenders to whomever will break test them on a machine that we can at least ghetto-calibrate by breaking something of known load rating first, and take our numbers from there.

Can do! DM me if you're serious. I have done plenty of work with HN2 and may be even to help get them on Jenk's test bed.

|

|

|

Climbing Weasel

·

Dec 21, 2024

·

Massachusetts

· Joined May 2022

· Points: 0

9kN?! My cordalette is stronger than that.

|

|

|

Ben Zartman

·

Dec 21, 2024

·

Little Compton, RI

· Joined Apr 2024

· Points: 0

Mr Rogerswrote:Kyle,

Thanks for fighting the good fight! lol.

I took a break from this thread as Ben Z. can not for the life of him be humbled.

He states multiple times my clearly superior products. Which is so based in ego its mind blowing, and part of the reason its hard to be constructive in discourse with him. HE IS RIGHT.

Dude is so in his own world, he doesn't realize major MFGs have made products that fill the holes in gear that he's attempting to fill....at 1/4 of the cost.

He ignores that there has been 1000's of tests using aramids and HMPE, and thinks that somehow sheathing some SK99 is going to change the reduction of 40% in those types of fibers when knotted. Hint, it will break in the knot with about 40% reduction in strength.

He ignores advice from people who might actually have more knowledge than him in some areas of rope craft.... Then he back handedly insults folks as basically being dumber than him for questioning him.

Claims above,In the world of rigging, a hitch is not a knot....as a rigger in the world this is not true, many of us know a hitch is a type of knot, saying go tie a clove hitch doesnt somehow mean you're not tying a type of knot. I don't get why he gets to be pedantic, but not Mark.

In the end so many claims he makes around superiority, IMO, means the onus of proof lies with him to back up those claims. I'm waiting for that moment, but get a lot of defensive hot air thus far.

I applaud this man in getting his products certified, thats not easy. I applaud his want to push rope craft into the next decade. But I do not applaud his bullheadedness.

Cést La Vié.

EDIT: To that end, my offer of five Anchor Extenders to whomever will break test them on a machine that we can at least ghetto-calibrate by breaking something of known load rating first, and take our numbers from there.

Can do! DM me if you're serious. I have done plenty of work with HN2 and may be even to help get them on Jenk's test bed. You're on, Mr Rogers, DM incoming! I only ask again: how many MFGs don't believe their products are the best? I'm getting a lot of shade from people who are determined to deny that my products are the best, without having seen or used them. How shall I prove it, if not by describing in what their betterness consists, which I've done several times: Lighter (my shoulder-length weighs .63 OZ V. a sewn spectra one at .71 OZ) Stronger: mine, 24kN; spectra sewn, 22kN. I'm willing to dial back and apologize to Kyle (done so above), and concede that he made some good points. And I'm willing to submit samples for testing. If it seems like "bloviating" to say "I have something better than seen heretofore," I'm at a loss to know how to talk about it. I didn't begin this thread to talk about any of my products at all--I began it to see how the community would react to the idea, in use in other places, of a lashing between two eyes, and we drifted into strange waters. I could continue to argue about whether a hitch is a knot, but that's academic--I changed the title of the thread to accomodate the view here. I harbor no hard feelings toward anyone, and I'm sorry that strongly believing my opinions upsets some: you all seem to hold to your opinions just as strongly. Anyway, once testing has been done, we can adjust expectations accordingly. If Kyle's chart is already correct, I'll endorse it. If it's off, maybe he'll update it. Peace to you all.

|

|

|

Brocky

·

Dec 22, 2024

·

Unknown Hometown

· Joined Jun 2016

· Points: 0

You have some nice looking products, but not sure they are the best!

|

|

|

Ben Zartman

·

Dec 22, 2024

·

Little Compton, RI

· Joined Apr 2024

· Points: 0

Brockywrote:You have some nice looking products, but not sure they are the best! Love to see more info on those...MFG? Rating? Material? I've made some Technora/polyester blend covered friction loops for arborists, but I can't get past thinking a full-Technora jacket will present the most friction. It's not super-pretty, being just a plain charcoal, but for maximum friction and heat dissipation, Technora's the stuff. Thanks for posting that, tho'

|

|

|

Brocky

·

Dec 23, 2024

·

Unknown Hometown

· Joined Jun 2016

· Points: 0

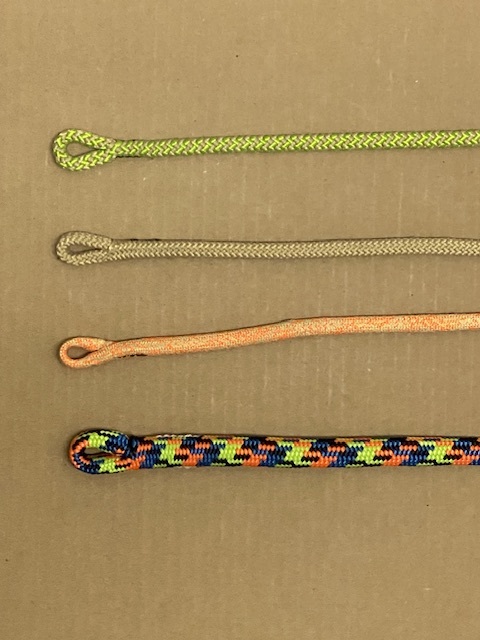

From the right, Petzl Rad, PUR, Beal’s BUL, Camp’s Cordino, NER’s PolyTech, all using Samson’s Tuck-Bury splice. The next is BailOut cover only splices, the cover tails bypass each other. The next is TRC cover with two passes of 1.75mm Vectrus, with straight buries. The last is V.elo’s 6mm DyTech, which has a break strength of 5200 lbs, with Tuck-Buries, that retain 98% of the cord’s strength. Twisted, parallel strand cores ropes can be spliced, there are a few different methods.

|

|

|

Ben Zartman

·

Dec 23, 2024

·

Little Compton, RI

· Joined Apr 2024

· Points: 0

Brockywrote:From the right, Petzl Rad, PUR, Beal’s BUL, Camp’s Cordino, NER’s PolyTech, all using Samson’s Tuck-Bury splice. The next is BailOut cover only splices, the cover tails bypass each other. The next is TRC cover with two passes of 1.75mm Vectrus, with straight buries. The last is V.elo’s 6mm DyTech, which has a break strength of 5200 lbs, with Tuck-Buries, that retain 98% of the cord’s strength. Twisted, parallel strand cores ropes can be spliced, there are a few different methods. Thanks, Brocky! I've seen some of these flavors in use by arborists. I've long thought that it's time climbers picked up rope splicing as well. Maybe, just maybe, the door is opening a crack. Once it's accepted, the possibilities for gear development are endless. Perhaps we need a slogan: "Add some splice to you climbing life." "Get hitched with a lashing"

|

|

|

Serge S

·

Dec 23, 2024

·

Seattle, WA

· Joined Oct 2015

· Points: 683

Desert Rock Sportswrote:So... with two rope rappels, the knot, which should NOT be able to pass through the quicklinks... is actually a safety feature. You have eliminated that. By this reasoning, should rappelling with 1 rope include a "best practice" of tying an overhand-on-a-bight near the middle ?

EDIT: To clarify, I'm challenging the idea that the safety side effect Desert Rock Sports brings up (which he better illustrates on page 2 mountainproject.com/forum/m…) outweighs the risk of the knot getting stuck. I've never heard of a recommendation to tie a knot near the middle for 2-strand raps on 1 rope, so I am assuming the risk of the mid-knot getting stuck is generally considered more important than the mid-knot's 50% benefit in the event of 1 strand getting cut.

|

|

|

Marc801 C

·

Dec 23, 2024

·

Sandy, Utah

· Joined Feb 2014

· Points: 65

Serge Swrote: By this reasoning, should rappelling with 1 rope include a "best practice" of tying an overhand-on-a-bight near the middle ? You seem to be confusing a double rope rappel with a single rope two strand rappel.

|

|

|

mbk

·

Dec 24, 2024

·

Unknown Hometown

· Joined Jul 2013

· Points: 0

Serge Swrote: By this reasoning, should rappelling with 1 rope include a "best practice" of tying an overhand-on-a-bight near the middle ? That is completely ridiculous. Instead, you should rap off of a garda hitch.

|

|

|

Jared E

·

Dec 24, 2024

·

CO-based healthcare traveler

· Joined Nov 2022

· Points: 417

mbkwrote: That is completely ridiculous. Instead, you should rap off of a garda hitch. I’m gonna vom

|

|

|

Desert Rock Sports

·

Jan 2, 2025

·

Las Vegas, NV

· Joined Aug 2019

· Points: 2

I was pointing out that knotless double rope rappel loses a safety feature of knotted double rope rappel.

Single rope rappel, you can take the time to add it if you want... or if you are using a GriGri you will add it anyways.

|

|

|

Spencer Shields

·

Apr 19, 2025

·

Vancouver, BC

· Joined Oct 2015

· Points: 467

@Ben You should get in touch with Mark Smiley, he's experimented with putting a non-load bearing splice into the ends of his own ropes to make it easier to do v-threads while ice climbing. I don't personally see the applicability of this for my own climbing, but I'm sure there are people who do.

|

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook