Back up line?

|

|

How many of you use a secondary lifeline for re-bolting and bolting of new routes? Other than when using cutting tools, do you think it’s necessary and what is your method? |

|

|

For rebolting I’ve started using a second line more often than not, especially when the approach isn’t terrible. It gives me the warm fuzzies looking up and seeing independent ropes, often makes positioning easier, and makes it more convenient hanging tools out of my way and off my harness. the longer I do this, the more I’ve moved toward rope access systems rather than regular climbing systems. I think it’s worth the extra faff especially if doing it a lot. |

|

|

Peter Thomas wrote: Awesome! This looks very similar to what harnesses like the Petzl Astro BOD are implying with having two lines. I’m considering purchasing an Astro sit fast since I have a program discount for Petzl items to use with the devices and techniques that follow the IRATA systems of rope access. I’m more worried that using two lines will lead to a more clustered system especially re-bolting where I am carrying several more tools. |

|

|

I use a second line for rebolting almost* every time I go out, but it's less for a backup, and more for organization/comfort. It's nice to leave the bag and tools on the other line so you can get the weight off and clear space to work. I'll attach to the other line when I use a grinder but other than that I don't feel like it's necessary. |

|

|

I rarely use a backup line (if you do... using Petzl asap style device as a backup device that protects for the up and the down beats a microtraxion), but I have made a habit of never jugging a line over an edge without a redirect. This usually looks like using an removeable "exploratory" bolt soon after breaking the edge of the cliff or a mini anchor off a good piece or two. I've noticed a lot of newer developers not doing this and coreshotting their ropes, and then seeking edge pro instead of a redirect. Edge pro is great a redirect is better. I'll use both if the edge is sharp, and just the redirect if it's smooth. Here in the Southeast where there's plenty of trees, elevating the rope off the rock/ground at the cliff edge with a redirect through a tree helps too. I used to always use a grinder when needed, a friend put me on to an oscillating tool with carbide teeth and it definitely beats out the grinder hands down and no more worries about nicking your rope. |

|

|

DrRockso RRG wrote: After jugging up while staring up at my third (yes 3rd) coreshot section of dynamic line I'd dedicated to rebolting work, I immediately went out and bought 300' of 10.5mm static line. I usually double it over and use one side for a backup and one for my primary. I often rap in with an extended GriGri attached to a belay seat, and hang most of the heavy stuff off of that extension to get it off my person but still within easy access. Works very well. And redirect, redirect, redirect! Always. And if you can't, edge protect until you can. Dr., what oscillating blades do you prefer? Those carbide ones are pricey. And I can't see them lasting that long or really helping battery life out much. Curious to try it though, especially as an alternative to rapidly spinning motorized ninja stars! |

|

|

Andy Bennett wrote: How on earth are you getting those blades to last? Even in carpentry their lifetime is measured in minutes and they’re super expensive. |

|

|

DrRockso RRG wrote: I'm not knowledgeable about oscillating tools, can you point me to one of such diddlyboppers? Is it any oscillating tool or is it a special one? Thanks |

|

|

Just about every power tool brand has a cordless oscillating tool, I'd just go with whatever battery platform you're already on. Just Google carbide oscillating tool blade, dewalt has them for about $13 each, not cheap but you get what you pay for. I've had good success on 1/4" stock glue ins. I haven't had the opportunity to try it with 1/2" sleeve bolts. |

|

|

Climbing Weasel wrote: Right?! I've gone through an entire blade just trying to cut off one ornery 10d nail that was in the way of some new molding during a remodel. |

|

|

Andy Bennett wrote: I know! Even with the fancy overly expensive carbide versions a nail completely wipes them out. I can’t imagine going through an actual bolt. |

|

|

Here's a blade for you. You get what you pay for, tools aren't overly priced if they work and last awhile. If your going through a blade on a 10 penny nail you had a cheap blade. Give it a try, you're much less likely to marr up the rock with an oscillator than a grinder. The expensive blades aren't a big deal for the rare occasion a cut off tool is necessary. https://www.acehardware.com/departments/tools/power-tool-accessories/multitool-accessories/2028331?x429=true&gad_source=1&gclid=Cj0KCQiAvP-6BhDyARIsAJ3uv7ZoCcHfpPc9xf57Lt_bDNy4JpOdfDx2oviqO6MoLyqw9nSJcAWSdR8aAuAaEALw_wcB&gclsrc=aw.ds |

|

|

DrRockso RRG wrote: Ahhhh. Interesting; this is a diamond blade, like for tile. I’m only familiar with the carbide toothed versions for heavy duty construction nails and wood, which last maybe a cut before the teeth break off and dull irreparably. Will have to give this one a shot. |

|

|

Climbing Weasel wrote: I actually linked the wrong one, apologies. These are the ones I use. |

|

|

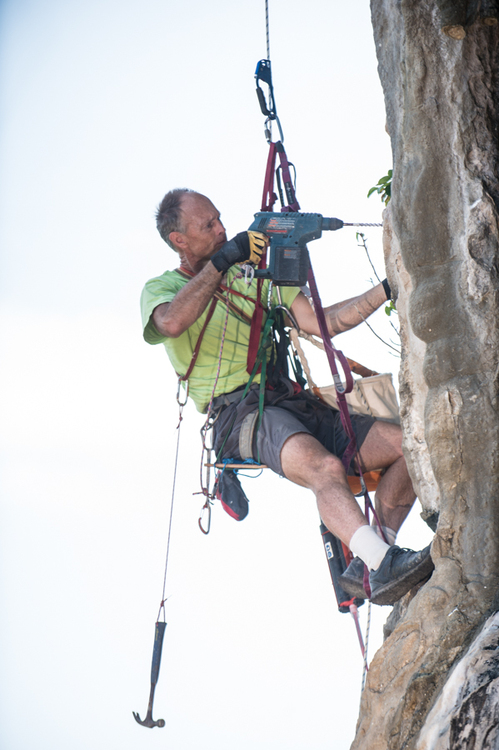

almostrad wrote: FWIW, my bolting-mentor set me up with a bosun's chair that has two gear-loops positioned on both sides. You can see the glue-gun hanging on my left, and the drill will go back on my right when finished with this hole. The only weight that I have on my body is the hammer and perhaps a sling or two. Everything else is either on the chair or hanging in a bag from the strong point leaving a more open workspace. And it's a LOT more comfortable than hanging in your harness and doesn't require a second line, although the safety aspect of the second line is nice. EDIT: The seat is just 5/16" plywood with a foam pad to sit on. |

|

|

John Byrnes wrote: Hey John, are you typically ascending or descending the fixed line with that setup while drilling? If both, do you find one direction easier with the chair? Rappelling seems pretty straight forward with a chair, so I guess I'm curious how ascending the fixed line goes with it? I have a bosun's chair that I've never used but my body is beginning to suffer long hours in the harness. Thanks! |

|

|

KrisG wrote: Obviously you gotta come back down but I'm ascending while drilling (using a 20min. gel time glue, so I can drill, brush, blow, set and then jug). But I use the chair on my cleaning/ticking passes, too, since they usually take longer than the drilling pass. Going down is easier of course since when going up, even though your body-weight isn't on it, you have to pull up the chair (and everything hanging on it) with your right hand (pulling the rope through the Grigri.) It's a bit of work but creating a new route is a LOT of work. |

|

|

Climbing Weasel wrote: The key to metal cutting with an oscillating tool is patience. I cut galled up stainless steel fasteners multiple times a week and easily get 15-30 cuts of 3/8” bolts out of one carbide multiblade. If you push too hard you can trash a blade in 10 seconds. If you’re patient you can get a cumulative 30 minutes of cutting out of one easily. I use the dremel brand carbide mutliblades and love them. Go through maybe 6-8 a year building campervans full time. I’m curious now though how a tensioned rope will hold up to a fresh multiblade. Might have to do some workshop science. I wouldnt be surprised to see a sharp multiblade make short work of a tensioned sheath. |

|

|

For the oscillating tool, you really only need to get the cut started (about 1/4 thru). Then take your hammer and tap it back and forth and it will break off flush with the rock nearly every time. |

|

|

Andy Shoemaker wrote: I'm also curious about this potential hazard. We've probably all seen weird things happen climbing/rebolting/shenanigans, and it may not take much to have something catastrophic occurr. Paging Ryan Jenkes.... |

|

|

John Byrnes wrote: Nice. I use a work seat too, but when I have a lot of tools on me I still feel the weight when I swing around or jug. Usually not a big deal but if I can't get great positioning to the hole or I'm leaning out for whatever reason, it's nice to be a lot lighter (so having everything on the other line is nice.) Anyone spending more than 15 minutes working on a rope without a seat is totally blowing it though |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook