Hurley Jr. Parts List/Instructions

|

|

I tried searching through the forum, but got burnt out really quick and am now being lazy. Does anyone have a link to a parts list/instructions to make a Hurley Jr? (the round aluminum one) I've been using the latest iteration (hex tubing w/funky wrench) but don't really like it as much for a few idiosyncratic reasons. I just trained some new folks who want to build their own and want to get them instructions. |

|

|

https://www.google.com/url?sa=t&source=web&rct=j&url= geir.com/wp-content/uploads…;ved=2ahUKEwjryLTA2tH-AhVslGoFHR55A8MQFnoECB4QAQ&usg=AOvVaw0w9g5rEXa3rtcOUkJnLTL1 |

|

|

Thanks! |

|

|

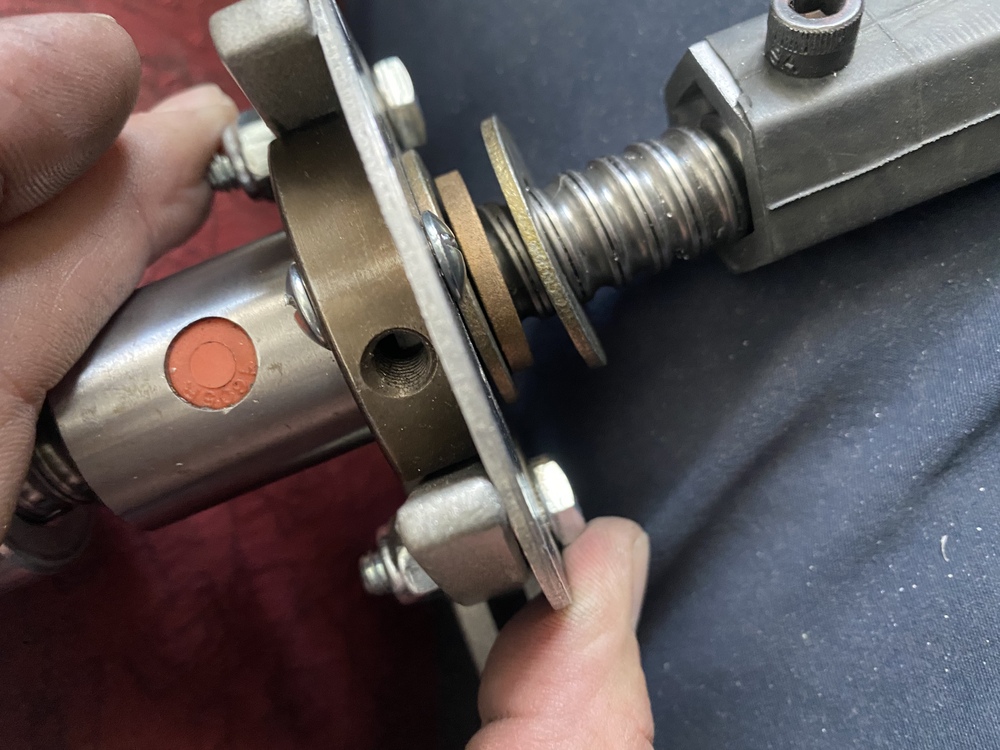

Hi max, I was making/giving those out for a while. If you don’t have a 3d printer for the flange, I found these from McMaster worked well. You just need to make sure you match the ID of the tubing for a light press fit.https://www.mcmaster.com/products/bushing-bearings/oil-embedded-flanged-sleeve-bearings-7/plain-bearing-type~flanged/plain-bearing-type~flanged If you do one of those, with a thick grade 8 washer you could ditch the thrust bearing which is the most expensive part. I think the doodad is a far superior puller with some querks. I don’t link that the hex nut can jam in the tubing. Using an all nylon nut reduces this (in combination with a steel locknut has worked best for me) I also don’t like that the handle can flop around. |

|

|

For the piece that goes inside the tube to keep the bolt from falling out, I just used a piece of pvc pipe. Drilled and tapped a couple of holes in the side of the tube and secured the pvc with a couple of screws |

|

|

If anyone is looking for the hurley SR info, it is here: I don't think Geir has any info up on his site anymore. https://drive.google.com/drive/folders/1WaYzGxmvxC-sZcsdtoCLF7YbObb8_tN4?usp=sharing |

|

|

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook