Petzl Ice Tool Failures (Current Generation Quark, Nomic, and Ergonomic)

|

|

Dick's Climbing in the UK indicates an MSRP of 265 pounds (currently $335-340 USD) for the BD Hydra. As a point of reference, Petzl Nomics have an MSRP of 270 pounds (currently $340-345 USD) on their website. So, it appears that the pricing between the Hydras and Nomics will be comparable. |

|

|

Artem Vee wrote: Still high if you are talking USD. |

|

|

Kyle Tarrywrote: Kyle, I disagree that ice tools should be allowed to have catastrophic failure modes that have no warning. These are not disposable, single use products. I think your average climber should be able to perform a die penetrant inspection, with guidance from a manufacturer. This is far preferable to having tools be completely uninspectable. It is common practice to place the expected point of initial fatigue failure at a location that is easy to inspect and then provide an inspection procedure to the user/operator. If you have a better suggestion, I am all ears, but the current status quo of having absolutely no safety regulation of fatigue failures on ice tools or crampons is far from ideal. |

|

|

Karl Henizewrote: That's a nice idea but....I would be really surprised if that happened. Maybe in industry, but not with consumers. For example, in the bike industry, which is a good comparison in this case, it's unheard of for a consumer to do a fatigue dye check, or for a manufacturer to reccomend that, or somehow guide consumers through the process. In addition, in this example, where would one even put the dye? The breaks seem to be deep in the plastic. Since this has been on-line for a while now, in both the US and the UK, and there has not been a tsunami of reports, I don't think we'll hear anything from Petzl until or unless somebody really hurts themselves. They might make some quiet in-line changes (I hope they do) but apart from that I think they had their chance, and appear to have decided that there is no problem, or that it's too costly to change until the next generation of tools. |

|

|

Karl Henizewrote: Get real, Karl. You know most climbers can't be arsed to do a basic inspection of their ropes even once a year, and you expect them to read a technical procedure, get all gloved up, masked up, and dive into a dye penetrant test? Ain't gonna happen. Well, with you as the one exception, maybe.

Again, you're going down this road based on an unsupported conclusion - that Petzl tools should be expected to suffer fatigue failure within their normal service life in a normal use case. Maybe, maybe not - we just don't have evidence to support that assertion. In my humble opinion, 6 (or is it 7?) pics of broken tools on this 13-page thread, with only one first-hand account of a failure, does not meet that threshold. Also, in what industry/context are end-user fatigue inspections of consumer goods common? Certainly not in diving (trained inspectors do annual visual inspections and 5-year hydro tests on cylinders). Bikes? Never heard of such a thing. Aviation? Pilots aren't doing their own structural inspections and signing off on them. What else?

Fair enough. My reading of the UIAA standard (which incorporates the CE standard) seems to confirm that the testing is done on a one-off basis on a single sample. It also seems to be more geared toward mountaineering axes than ice tools. It might be time to update and expand that test to include a certain number of stress cycles, but no amount of screaming on MP is going to bring about that change. It's probably unrealistic to expect it to happen, given that it would need to involve machinery to put the tools through something like a million simulated swings at ice (how do you even simulate that?), a million simulated cleans from ice (again, how?), as well as a million straight pull cycles, probably at each grip position independently. The best we can do, as climbers, is understand the limitations of the testing and not assume that our tools are infallible just because the have EN and IUAA stamps on them. If you want to take your tools down to the lab for NDT after each day of climbing, go for it. I'll worry about other things that could kill me more readily. EDIT: Apologies to Bruno for the repetition; I take too long to type these things. |

|

|

No problem Grant. Just to add, we have no don't even know that these are fatigue failures. I suspect that they are generally not, especially with the newer tools. There are so many possibiliites: some of the alumimum inserts in the handles have poor quality with sharp edges or incorrect treatment, sloppy fitting to the handle, bonding to the plastic, voids in the construction, clearance with the rivets, and so on. Just not enough information. I do hope that somebody at Petzl has taken a good look some of these tools. |

|

|

Grant Watsonwrote: I agree with your points, but Paragliding might be the one area where pilots (end users) are expected to perform trim checks, porosity checks, and otherwise airworthiness inspections on a flight hours schedule. Some of these require specialized equipment that not everyone has, but it's still on the user--it's not like you drop it off for annual A&P like powered flight and no one is issuing/revoking certs even though there is a finite lifespan for every wing. With all that, you're not supposed to re-pack your own reserve chute. |

|

|

|

|

|

Cole Crawfordwrote: Yeah, it's weird he didn't come on mtnproj and say there is a problem with petzl tools... he just bought a new pair and then climbed the moonflower with them and went on with his life.... |

|

|

Cole Crawfordwrote: The bottom sentence is most concerning… |

|

|

Li Huwrote: Yea someone post the rest!! |

|

|

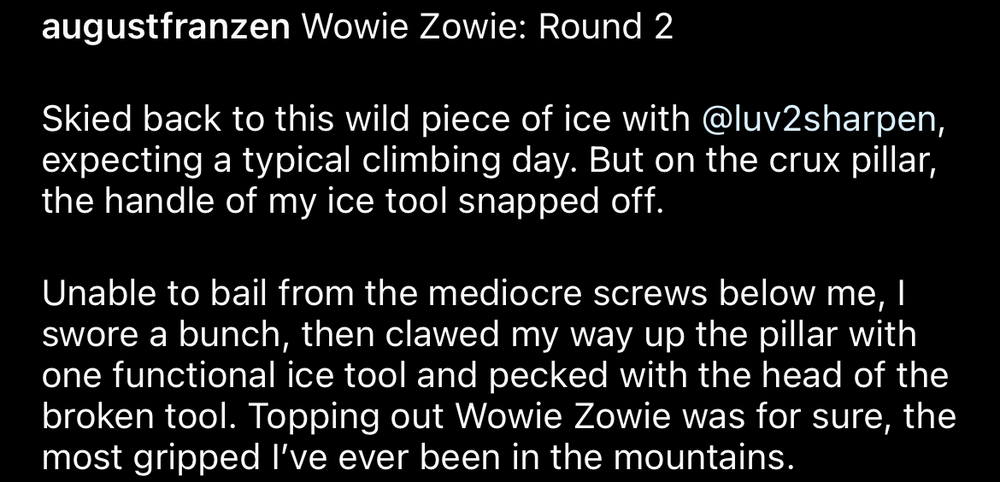

drew Awrote: https://www.instagram.com/p/CMVmPVsFs_K/?igsh=N3d4a3l0OXk2M3pl |

|

|

Finn Lanverswrote: Sounds like a great review of Nomics, why doesn't Petzl publish this on their product page? |

|

|

can't Imagin not firing in a screw asap! A major part of my game is that providing there is at least 7.5cm of ice I can get a scew in any time, any place.. |

|

|

He’s was on a pillar. Sounds to me like he couldn’t put a screw in. |

|

|

There's pillars and then there's pillars. Most will take a bail screw.. |

|

|

Nick Goldsmithwrote: Wowie Zowie |

|

|

Skibowrote: Wowie zowie! |

|

|

Melanie Sheawrote: That almost makes me feel better about X-Dreams, if there is a sign of excessive stress in the form of bending, I would take that over a total failure. |

|

|

(Edited to make less verbose) Karl Henizewrote: I get what you're worried about, but I think this is overly broad. Almost everything we use in climbing (and daily life) has catastrophic failure modes without warning, the key is that the safety margins are sufficiently high such as to make the failure rate low.

Lots of gear has critical failure points are hidden and uninspectable. Cam stems, cam shafts, Grigri shafts, microtrax shafts, ice axe head rivets, ski binding release mechanism, etc. I am not aware of any of these things having manufacturer provided fatigue inspection criteria, certainly none as complex as die penetrant. A car/motorcycle/bicycle is full of critical safety items that see cyclic loads which are neither accessible nor is there a provided procedure for die penetrant inspection (ball joints, internal steering rack components, brake linkage, aluminum motorcycle frame, suspension arms, rotating parts inside your transmission). I doubt that anyone is doing a detailed inspection with die penetrant of all these things that could catastrophically fail (but are unlikely to do so).

The potential problem with the new Nomics isn't a lack of access and penetrant die inspection procedure. If that was the case, this would be equally problematic for all ice tools, because none of them have penetrant die access or procedures. It's simply that something (design, manufacturing, whatever) results in a tool that may have a failure rate that is above the acceptable level. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook