Petzl Ice Tool Failures (Current Generation Quark, Nomic, and Ergonomic)

|

|

Artem Vee wrote: Heavier less skilled climbers will likely put more stress on the tools as well. That’s where my concern originated. I’m 188 pounds. Add clothing, gear and boots well over 220-230, and I can swing much harder than most normally built climbers. They’d also likely hit the correct points of contact in less throws and land more “softly”. This is especially important for mixed conditions. Arguably, someone like me may stress the tools much more than even a high mileage normally built and better skilled climber. This failure mode is still frightening to me, but since I’m aware of it, I plan to “baby” my tools. In the future, will likely get “Elite” tools with Kevlar/Carbon handles. |

|

|

Artem Vee wrote: There's irony in yours as well. I just don't know where to start. I guess I'll go back to my original point... Of the high mileage users, the documented cases of tools failing in use is in the low single digits. There are enough failures of all brands of tools, crampons, etc that concern over Petzl specifically in this matter is out of proportion. It's actually probably more out of proportion, given the number of high mileage/hard climbers who are using Petzl tools. Ironically, you speak to the "power users" statistic ability to find the limits but ignore the statistical evidence that even among the "power users" this number is infinitesimally small. I never said that it's impossible for the failure to occur. My point was that (at this time) it's so unlikely to happen that one should put it out of mind and manage much more threatening and higher probability threats. There's also the matter of acting as if this as the only failure that has ever been seen in ice tools. Picks break, heads come loose, pommels break, shafts break, etc. A quick search on this very forum will bring up results showing failures from every manufacturer. The hand wringing over Petzl alone is nonsensical. If one is to take your stance on this matter...there aren't any tools that can be trusted. I'll also touch on the irony of the fact that my original response was to a user who hadn't even taken his tools out of the packaging yet and was thinking about returning them pre-emptively. You totally ignored that part. The likelihood is that he is most probably not a "power user" if he's fretting over this on the internet and not at the crag drytooling and watching partners break picks, pommels, shafts, and grips of every brand out there. And again, I don't disagree with you inherently. I took a bit of issue with your snarky retort making implications about my intelligence, given that you used quite a bit of cognitive dissonance yourself to get there. But I do agree with what is the real conclusion... If one is a high mileage, hard user of their tools... it makes sense to replace them much more frequently than the occasional user. |

|

|

The ice picks that shipped with my x dreams both snapped off an inch from the tip, both times on lead, in the first two seasons. I returned them for r&d and they sent me a bunch of new ones. No issues since. I would guess they weren't the only picks in that batch.. |

|

|

Highly unusual for such soft malleable picks. I've bent mine but never snapped them. Switched to Howey Tool picks and have never looked back. |

|

|

|

|

|

Christian Donkeywrote: Lol Nate and Artem are both right. There are likely millions (if not tens of millions) of hours of nomic use per year in the US. We have a half dozen failures here, and assume theres 20x more out there unreported. So 120 failures per year, out of millions of hours of use. Gear breaks. Especially if you beat it up like i do and like others do. Maybe be careful cranking on it sideways on a mixed route like the earlier poster suggested, and worry about more likely things. Other tools break from other manufacturers. Picks break all the time. Often enough that if I was solo ing a very big route I would consider carrying a third tool. It’s a bit of a dated reference nowadays but this is even suggested in Mark Twight’s book.

|

|

|

that said I'm going to buy those DMM Cortex tools when they come out |

|

|

John Sigmonwrote: I'm not arguing against the statistics, I just don't think that the same mechanism of failure is merely a coincidence. I agree, most climbers thus far have not experienced this failure and most likely won't. However, it seems apparent enough that the tool has the capacity to catastrophically fail in this way, and to me, it is no longer a tool of choice. There's simply better options available for a multitude of reasons in 2024. |

|

|

The thought of a tool breaking like that while soloing (or even leading in a lot of circumstances) is very spooky to me. I’m trying to think of an equivalent risk of gear failure on rock… maybe harness failure when aid soloing? Rubber delamination off a shoe? Maybe there’s a better one I can’t think of but my point is that either of those are EXTREMELY unlikely and easy to predict based on unusual wear, whereas a tool snapping like that is potentially catastrophic and, in my opinion, something people shouldn’t have to factor into the decision making process. 120 failures per year seems unacceptable to me, especially when, as Christian said, there are plenty of other options out there. I may have missed something in all the comments, but were there signs of impending failure in any of these cases? Other than just heavy use of course. |

|

|

Nick Niebuhrwrote: I think a hold breaking is the main one you're not thinking of. |

|

|

I don't think anyone here is wrong, and certainly bringing failure rates closer to zero would be great. I do think it's worth considering this from a mechanical engineering perspective where the failure rate is considered, and it's a given that it's not zero. If more reports continue to surface I'd be more likely to give mine up. As it stands I'll probably move to a different tool later when it's convenient, and plan to climb with my nomics tomorrow. Unfortunately it's really hard from the outside to tell what the failure rates are unless Petzl publishes numbers.. only they know. As an aside every time I have warrantied gear that broke the rep said "we've never heard of this before" to find out later that it was a known issue with the manufacturer :) Given my personal communications with Petzl, if this was a larger issue I would be surprised if they made any announcement or recall so maybe it is larger than we think! Consider this excerpt from BD about crampons (https://www.blackdiamondequipment.com/en_EU/stories/experience-story-qc-lab-gear-doesnt-last-forever--crampons/)

|

|

|

that picture from NH is super spooky. as an avid soloer its makes you think..... I permanantly gave up on BD tools after I had 4 picks break in two season and BD said it was my fault... switched to petzl and cassin and not a single breakage since... |

|

|

Li Huwrote: Hundred thousand ice tools throughout the world, I’ve only heard of 3 breaking like this. Odds seem pretty good. But I did have a 7 year old petzl toe bail snap on me… |

|

|

Grant Watsonwrote: I mean gear failure, a hold breaking is more of an objective danger than gear failure, like a detached dagger coming off. At least that's how I see it |

|

|

Nick Niebuhrwrote: I see the correlation since tools are your holds when ice climbing. |

|

|

Nick Niebuhrwrote: I understand what you're saying, but you were looking for analagous failure modes, and I would say that's it. Probably a similar, tiny liklihood of either happening to any given climber on any given day, with similar, possibly disastrous results. Of course, one of the things that we don't know from the few "I know a guy..." reports is whether the break occurred when swinging or when pulling (the latter more likely to lead to more "exciting" outcomes). I've yet to come across a handleless tool on a route, so I'll keep swinging and pulling on my Nomics with confidence until I see some compelling evidence that I shouldn't. |

|

|

that last photo was pretty compelling.. yes the ice tool is the hold... friend of mine had the handle come off a Grivel machine in Canada on WI6. It was BINTD of leashes and third tools so no fall and finished the route. now with leashless the norm a fall is likely.... |

|

|

Grant Watsonwrote: Not sure what rock you're getting on, but I've had more holds break over the last year than there are pictures of broken tools in this thread. But I think your point still stands and the analogy can be extended. When soloing rock, you're aware of the potential failure mode of a hold breaking and you mitigate that by changing the way you climb. Likewise, I'd imagine it might be sufficient to recognize the potential failure mode of torque on the handle attachment point for these tools. Avoiding applying force in that manner in general, but especially when soloing, will reduce the risk even more towards zero than it already is. |

|

|

I think the discussion on failure rate may be missing the point of what is so concerning with this failure mode - there is no good way to inspect the tools for fatigue cracks at this location. Based on the limited information that is available (and none appears to be forthcoming from Petzl), I think it is fair to surmise that these are all fatigue failures. While there will be some variability in how many fatigue cycles it takes for a crack to grow to the critical size, the question for the climber is when the fatigue failure will occur and not if it will occur. Without any information from Petzl, I think it is fair assumption that these tools will eventually fail due to fatigue. Maybe some people will retire their equipment or stop climbing thereby preventing failure, but I think it is fair to assume that climbers will run their tools to failure absent a compelling reason not to. The S-N curve above illustrates that there there is no endurance limit for aluminum alloys and that even "perfectly" manufactured ice tools will eventually fail in fatigue. Typical "good" practice for safety critical equipment that can be run to failure and fail catastrophically is to provide the user / operator with an inspection program that allows the user to find fatigue cracks before they reach a critical size and fail catastrophically. I see no reasonable way to inspect current gen Nomic or Ergonomic for fatigue cracks in the handle. The best inspection method I can think of is:

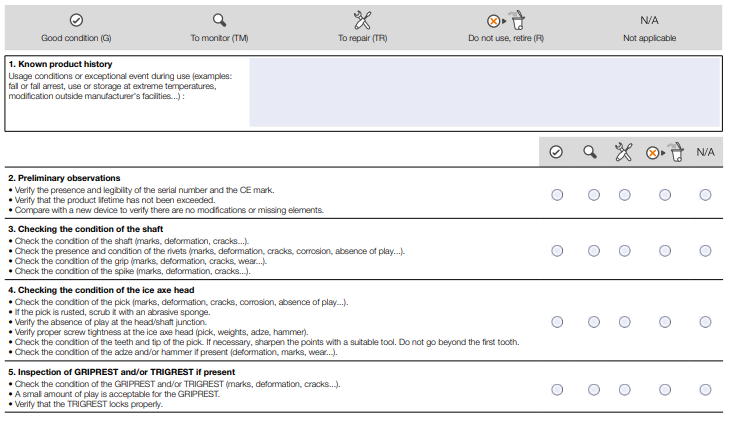

Most people don't have the tools or skills to do this effectively. The few that do would still find it onerous. So, practically no one will do this. In at least two of the examples thus far, the failures seemed to occur without any warning. So, I don't see a way to avoid this fatigue failure mode without inspecting the handle for cracks or preemptively retiring the tools, without knowing the remaining fatigue life. Petzl does provide some inspection guidelines and a inspection checklist on their website (https://www.petzl.com/US/EN/Sport/Ice-axes/NOMIC), but they are obsolete and should be updated to address this failure mode. |

|

|

Karl, I have no bone to pick with you and no skin in this game (climb on Petzls if you want, otherwise don't - I don't own any stock). However, as someone said above, let's keep some sense of perspective here. Posting fancy graphs without any explanation for us laypeople of what they're supposed to tell us is a bit much. Whatever that graph is supposed to show, it looks like Aluminum and Steel are pretty similar through 10 to the 6th power cycles (sorry, can't seem to format that properly here). That's a million swings. Do you think there's anyone on the planet who's swung at ice a million times in a lifetime, never mind on a single tool? |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook