Yet Another Bolt Remover

|

|

Hello, I would also be intersted to get one in Vietnam! Is it useful to file the form now or should we wait? |

|

|

Thibaud Vantalonwrote: Hi Thibaud, If you can fill the form now, that would be great. It's how I keep track of who is interested to email once they are ready. |

|

|

Ok great, I filled it. Thank you. |

|

|

Filled out the form twice with no reply. Now wondering if you are still making the YABR ? I would love to buy one if you are still making them. |

|

|

My machinist just handed me a box of parts. I will get them to the anodizer today and off to Peter for assembly when they are done. |

|

|

Hi Cleatis, Peter and all. I am mechanical design engineer working in a French aerospace company in Mexico (yes, I am Mexican) and I am also an enthusiastic rock climber. I was thinking maybe to make the machining, finish and the assembly here of the YABR, for sure will be cheaper to do it than the US, so we can all win. It is possible to have the 3D models and drawings, I use normally SolidWorks, but I can have them in any other software… please think of it, for any contact, my email is danielramos500@gmail.com |

|

|

Daniel Ramoswrote: The more people involved the better! I'll send the SW files and the BOM tonight. Casey |

|

|

Just filled out the form! Please let me know when you have some in stock |

|

|

|

|

|

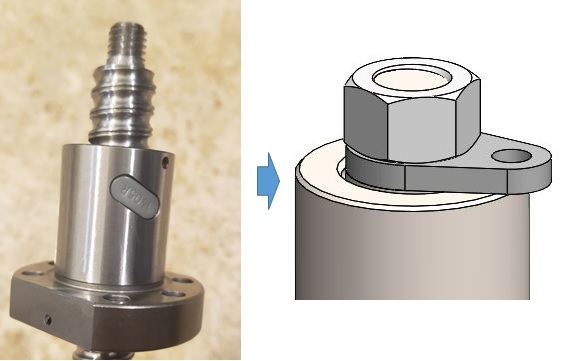

Hi Guys, finally I did my homework, thanks Casey to share the files of the YABR I made some updates to the design, taking the principle of Gregger Man, I add a 3/16 - 16 thread on the top end of the ball screw to just put a nut and I add a washer holder to put a 4 mm paracord on it, to avoid loosing your YABR : I also change the method to attach the puller directly to the spinner tool to reduce the switch over time, with 2 solid screws : I also change the size thread on the other top end of the ball screw, from 1/2-20 to 1/2-13, this because is cheaper and easy to find the hex couplers on this size (maybe also the 1/2-13 thread is robuster than the 1/2-20) and the common 1/2 bolt are this thread size : Finally the YARB looks as follows, with a good looking green anodized. : I made a quote of all, machining and buying most of the components locally (here in México). Unfortunately now the machining is not as cheaper as 2018 (so do the lead times), and to get a good price I need to make at least 10 pcs. The final price is 300 dollars, so I guess the only advantage is my location, maybe the shipping can be cheaper, I am considering in the price a hex coupling nut adapter for 3/8 and also 1/2 bolts. Tell me if you are interested, I would have to get at least 10 interested parties to launch the production. Contact me via email, danielramos500@gmail.com Thanks. |

|

|

Regarding the 1/2-20 thread: the reason for making the puller tool match the SDS chuck adapter is to be able to spin and pull without ever removing the coupling nut from a semi-loose bolt. Doing that is a pain since you need needle nose pliers to hold the bolt… |

|

|

Not to beat a dead horse or anything, but the 1/2 - 13 pitch is definitely not more robust then 1/2 - 20. The added pitch count is stronger, which has been confirmed for me by an engineer. There is definitely a good reason for the 1/2 - 20 pitch as Greg said above. The 1/2-20 Chuck adapter is a key part for spinning wedges, and it’s important for the adapters to fit both the adapter and the bolt puller. |

|

|

Hi Gregger Man and Tyler Stockdale, Yes if is the case that you use the 1/2-20 chuck adapter. In my case I use 3/8-16 double nut for twisting the bolt with any wrench or drive tool manually (if you don't have an electrical hammer drill/impact driver). Even you can use the standard coupling nut adapter (the one that I proposed 1/2-13 to 3/8-16) with a 5/8 socket nut using a SDS socket driver adapter (this way you even save having to screw and unscrew the SDS shuck adapter). This principle is also functional if you are using 1/2 bolts. For me this way is much easier and you can get all in Home Depot or any hardware store. Regards. |

|

|

Daniel Ramoswrote: Many bolts will not have enough thread exposed to double nut them after driving the bolt into the hole to release the expansion clip from the wedge. I don't this idea is going to catch on. |

|

|

timothy fisherwrote: That's why I am putting the other option to use the same coupling nut (but the 1/2-13 to 3/8-16, same form and fit as the 1/2-20 to 3/8-16) but with a 5/8 socket nut using the SDS socket nut adapter (see image above). Anyways, using nuts or coupling nuts, you can have space problems. |

|

|

I agree that 1/2-20 is the way to go, much quicker transition between spinning and pulling. As much as I'd hoped that Daniel could make YABRs cheaper in Mexico, I'm also not surprised as our units utilize reduced-rate machining along with me and Peter volunteering time. casey |

|

|

Using a 5/8 socket nut on the 5/8 hex coupling nut (doesn't matter if is 1/2-20 or 1/2-13) you can not even need to unscrew the SDS shuck adapter to make the transition between the spinning and the pulling, just saying. The issue is the qty required, the more quantity required, the cheaper it is of course. I could say that the price is between 280 and 300 dollars. Daniel |

|

|

Daniel Ramoswrote: Interesting. If I understand correctly, this approach means that you can't pull out on the bolt as you spin? Sometimes I don't even have to use a puller as slight outward force while spinning can be all that is needed. |

|

|

I also find that pulling out when spinning does a better job of notching the cone. |

|

|

Thanks for your work on this Daniel, I think most users will find the 1/2x20 thread more useful. The process of using the SDS Chuck adapter has proven to be the most efficient/fastest with the fewest number of items to carry. An early puller the Hurly Jr used a 1/2x13 bolt, and it was a hassle (among other issues) to need different and/or additional components. It’s telling that several sellers in china now sell these already machined to 1/2x20. I think rebolters are the only group requesting this, and you used to have to send in a drawing and pay an extra fee for the threads. I’d guess it took thousands of requests before the manufacturers started offering this as a “stock” option. I like the backstop to keep people from accidentally screwing the ball nut off. We’ve been using a 16mm shaft collar to achieve the same purpose. It’s OD is the same as the ball nut, so it has a hard stop, and looks nice. I’ve given up on having a tether. Any type of cord on the device inevitably gets wrapped up and in the way. Having it tie to the end would likely interfere with turning the handle. Don’t drop it has been the best solution I’ve found. Casey’s design with the small tie down is a nice clipping option when it’s not in use. Crusher a CO based rebolter used a steel ring around the tubing which could spin freely, and tied a keeper cord to that. That’s been the only workable solution I’ve seen for a tether. I was reluctantly hopeful you could get the cost down. I’ve really enjoyed assembling these, seeing where they go, and connecting with other rebolters around the world. Even so, they take a lot of time, and we don’t make any profit from them. Getting them out at the best price has been the goal since before I started helping with assembly and shipping. I do think your version will be more economical for people in Mexico and South/Central America. We include US shipping in the $275, but it costs an extra $50+ to ship internationally, and recently countries have been getting pretty strict about taxes. We are out of our current batch of YABRs but I think Casey and I are looking to start another batch to be ready in a couple months. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook