Do these bolts look right?

|

|

So I was climbing Pork Meadows, on Murphy's Dome and noticed that every one of the bolts had a nice shiny hanger but the nuts were rusted and the washers especially so. |

|

|

I can say this: I've bought "stainless steel" bolts that weren't, I learned after the fact. I have no idea what happened here, but yeah: mixed metals. |

|

|

The bolts look like red heads plated steel, the hangers are stainless . |

|

|

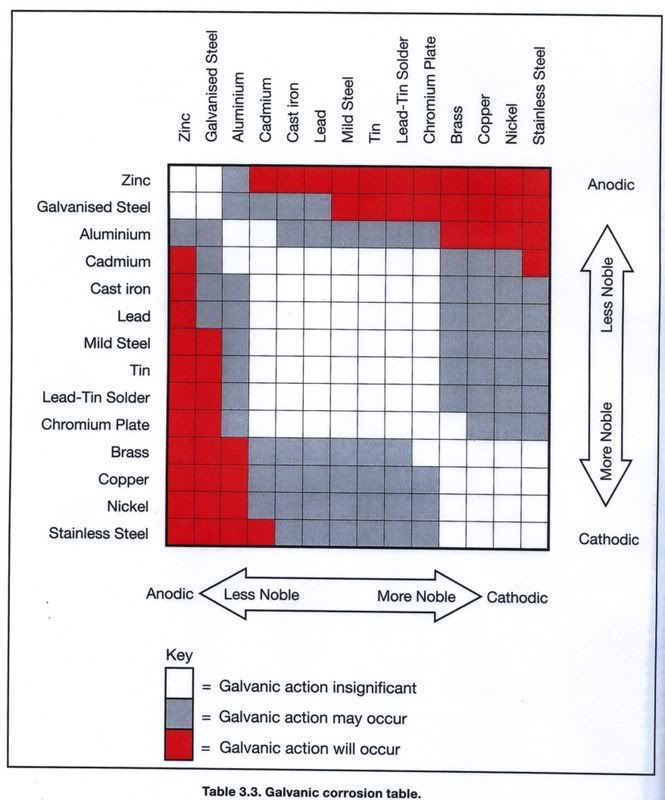

We all agree -- those are stainless hangers. Nope, no galvanic corrosion. That doesn't happen with stainless and common steel. |

|

|

You can always use the ol' magnet trick to check plated V. SS. Many SS in the climbing world are not magnetic, while plated is. |

|

|

If you can't see in the hole you don't know how bad it is between the dissimilar metals. |

|

|

John Byrnes wrote:We all agree -- those are stainless hangers. Nope, no galvanic corrosion. That doesn't happen with stainless and common steel. I don't know what the climate is like at Pork Meadows but if these are only a few years old, they are probably naked carbon steel. Whoever rebolted the route wasted their time and money (and created a hazard) since they need to be replaced again. The 20-year-old bolts that look good may be plated (Zn) steel or stainless, depending on climate, etc. Can't tell without more info.I'm no expert on galvanic action. But a quick Google shows many sources disagreeing with that assessment. Especially for zinc coated/galvanized steel. |

|

|

John Byrnes wrote:We all agree -- those are stainless hangers. Nope, no galvanic corrosion. That doesn't happen with stainless and common steel.Wrong. |

|

|

Jim Titt wrote: Wrong.Give him at least a bit of credit Jim, he is right that they are stainless hangers, and he's probably right that is isn't galvanic corrosion, he's only wrong that galvanic corrosion doesn't happen between stainless and mild steel. |

|

|

kennoyce wrote:and he's probably right that is isn't galvanic corrosionHuh? Corrosion is corrosion (oxidation) and it is pretty evident here. It is influenced by a range of factors its not an either or phenomenon. |

|

|

patto wrote: Huh? Corrosion is corrosion (oxidation) and it is pretty evident here. It is influenced by a range of factors its not an either or phenomenon.But there are different types of corrosion and galvanic corrosion is a specific process that requires specific conditions to occur and produces specific results which are not seen in the photos provided. Galvanic corrosion is actually quite rare in climbing bolts due to the lack of electrolyte presence. |

|

|

kennoyce wrote: But there are different types of corrosion and galvanic corrosion is a specific process that requires specific conditions to occur and produces specific results which are not seen in the photos provided. Galvanic corrosion is actually quite rare in climbing bolts due to the lack of electrolyte presence.Rainwater flowing across rock will quickly pick up electrolytes. The speed that those (presumably) zinc cover bolts rusted would indicate this. But please if you have some stronger arguments then I'm all ears. As I said I'm hardly an expert on the matter an I'm willing to learn. Do you just think it was oxygen and humid air that did this with not influence of galvanic corrosion? Please do elaborate. Because my experience with zinc plated bolts and galvanised bolts show much better longevity that presented here. |

|

|

patto wrote: Rainwater flowing across rock will quickly pick up electrolytes. The speed that those (presumably) zinc cover bolts rusted would indicate this. But please if you have some stronger arguments then I'm all ears. As I said I'm hardly an expert on the matter an I'm willing to learn. Do you just think it was oxygen and humid air that did this with not influence of galvanic corrosion? Please do elaborate. Because my experience with zinc plated bolts and galvanised bolts show much better longevity that presented here.Yes, rain will quickly pick up electrolytes, but for galvanic corrosion to take place the electrolyte must be present and in solution (i.e. in water) to allow the flow of electricity to cause corrosion. The area where these bolts are located (south platte) is a desert environment that typically receives around 15" of rain each year, the route is south facing and sunny, and the bolts don't sit in a water runoff area. All of these factors add up to show that there is very little time when an electrolyte is present. Will galvanic corrosion occur at times on these bolts, yes of course it will, but the percentage of time when galvanic corrosion would be able to occur is extremely limited due to the points I already mentioned. The corrosion in the first two photos shown is obviously uniform corrosion and doesn't appear to have any significant galvanic contribution (easy to tell because galvanic corrosion just occurs at the interface between the two dissimilar metals unless they are submerged in an electrolytic solution). The third photo is kind of hard to tell, but again looks to be mostly uniform corrosion, just not as advanced as the first two photos (look at the washer). My guess is that the zinc plating was removed to decrease the shininess of the bolts (this was a popular practice a few years ago where people would make the bolts (and or chains) less shiny by dipping them in vinegar not understanding that they were removing the protective zinc coating). Most likely all of the bolts in the area of a similar vintage are plated bolts on stainless hangers since that was just the accepted norm at the time. If this is the case, the reason for the corrosion rate disparity is the removal of the zinc plating on the bolts found on this route. |

|

|

you guys need me to fist-fight these bolts? |

|

|

kennoyce wrote: Give him at least a bit of credit Jim, he is right that they are stainless hangers, and he's probably right that is isn't galvanic corrosion, he's only wrong that galvanic corrosion doesn't happen between stainless and mild steel.Can you provide some more information on how the hangers must be stainless steel? Isn't it just as plausible (if not more) that the hangers and bolts are both low alloy/carbon steel, its just the hangers are platted? Or maybe the bolt is also platted but the act of hammering the bolt into the place removed the platting and the nut and washer are cheap-o's (no platting) from the hardware store? As you have stated the South Platte is a semi-arid climate (ie dry air and limited rain fall). Also these are not exactly high traffic trade routes. So there is very little, if any, mechanism to remove a good platting from the hanger through either corrosion or erosion. Finally, I agree that the bolts could be a hazard but once again could you provide more rationale? They could be perfectly fine and all you see is a bit of surface rust. If the hangers are held tight against the rock face then there is a pretty good seal to keep water out of the bolt hole. Also what driving force pushes the water back into the hole anyway? Gravity? Capillary action? Also, if you did get water back in the hole it likely would do limited damage as the there is no refresh and the corrosion becomes self arresting (the corrosion products saturate the water and cause it to become basic, corrosion is an acidic reaction). |

|

|

Mike Slavens wrote: Can you provide some more information on how the hangers must be stainless steel?Hangers are stainless because there are two petzl hangers (petzl only makes stainless hangers) and one metolius hanger of a design that metolius has only ever made out of stainless. Hardware store cheap-o bolts always come plated, you can't buy bare mild steel from a hardware store because it would be a rusty mess. Again, the hangers aren't plated, so the point about removing a plating from the hangers is moot. I never said that the bolts are dangerous, most likely they are perfectly fine for climbing on, but we don't know the condition of the bolt inside the hole. Water can get back in the hole in many different ways, several of which you mentioned, and then it can just sit in the hole for a long time causing all sorts of problems. Again, I'm guessing that all these bolts would hold way more than you could ever put on them in a climbing scenario, but it's still not a bad idea to just replace them with a high quality stainless bolt before they corrode to a point where they do become dangerous. |

|

|

Jim Titt wrote: Wrong.Jim or anyone, Show me proof of galvanic corrosion on climbing bolts outdoors (not in the lab) between plated (Zn) steel or carbon steel, and stainless steel (304 or 316) and I'll retract my statement. I've heard a lot of people say it could happen but I've never seen a case or heard of a case from a reliable source. |

|

|

kennoyce wrote: Hangers are stainless because there are two petzl hangers (petzl only makes stainless hangers) and one metolius hanger of a design that metolius has only ever made out of stainless.https://www.petzl.com/US/en/Sport/Anchors/COEUR-BOLT-STEEL#.VyJNIvkrLmE Petzl absolutely makes low allow/carbon steel bolts and have for years. Metolius currently only sells bolts that look like the pictures but are SS, but that hasn't been always been the case and I would argue this shift to primarily SS has been over the past two or three years where these bolts could easily be 10 years old. The bolt has no distinguishing marks other than the brand name so how can you identify it as a specific model? All their hangers are the same shape. kennoyce wrote: Hardware store cheap-o bolts always come plated, you can't buy bare mild steel from a hardware store because it would be a rusty mess.You can buy un-platted washers and I'm sure if you googled it enough you could find un-platted nuts. But you are right I could not find un-platted bolts. But knocking the platting off when hammering the bolt into the hole is still very plausible. kennoyce wrote: Again, the hangers aren't plated.Again, how are you so sure they aren't platted. They could be stainless, nothing definitively indicates they aren't, but why would someone buy just stainless hangers (expensive) but hardware store bolts? If someone went to the difficulty of buying and installing just replacement stainless hangers (indicating they understand the impact of corrosion) why wouldn't they also replace the bolt as well? |

|

|

Mike Slavens wrote:why would someone buy just stainless hangers (expensive) but hardware store bolts? If someone went to the difficulty of buying and installing just replacement stainless hangers (indicating they understand the impact of corrosion) why wouldn't they also replace the bolt as well?I've seen this too many times to count. Usually on older routes but even on newer routes I still see this happen. |

|

|

Mike Slavens wrote: petzl.com/US/en/Sport/Ancho… Petzl absolutely makes low allow/carbon steel bolts and have for years. Metolius currently only sells bolts that look like the pictures but are SS, but that hasn't been always been the case and I would argue this shift to primarily SS has been over the past two or three years where these bolts could easily be 10 years old. The bolt has no distinguishing marks other than the brand name so how can you identify it as a specific model? All their hangers are the same shape. You can buy un-platted washers and I'm sure if you googled it enough you could find un-platted nuts. But you are right I could not find un-platted bolts. But knocking the platting off when hammering the bolt into the hole is still very plausible. Again, how are you so sure they aren't platted. They could be stainless, nothing definitively indicates they aren't, but why would someone buy just stainless hangers (expensive) but hardware store bolts? If someone went to the difficulty of buying and installing just replacement stainless hangers (indicating they understand the impact of corrosion) why wouldn't they also replace the bolt as well?I have never seen a plated petzl hanger used in the US or even sold in any climbing store in the US and I've seen a lot of petzl hangers in my days. Regardless of this fact, if you have ever placed bolts (I've placed 100's) it is extremely easy to tell the difference between a plated and a stainless hanger, and the pictures on this thread are all stainless. You are right that plating can be compromised while placing a bolt, but this is a very localized issue and you aren't going to knock the plating off of a whole bolt, nut, washer, or hanger. As far as stainless hangers on plated bolts, at least in the US this was 100% the norm until the early 2000's. As I mentioned earlier, in the US prior to about 2000 (and after about 1980) you couldn't even buy normal sized non-stainless hangers. The closest thing you could buy to a plated hanger were the old Fixe stainless clad hangers which were mild steel in the middle with a stainless steel "plating" if you want to call it that. You could also purchase the metolius rap hangers which were mild steel, but those were only used for anchors. Even today it is still fairly common for cheap developers to place stainless hangers on plated bolts probably because the difference in price between a stainless and a plated hanger is almost negligible when compared to the difference in price between a stainless and a plated bolt. Edit to add: I looked a bit more at the petzl page and noticed that they have completely revamped their bolt and hanger lineup. I am almost 100% sure that petzl did not manufacture or sell non-stainless bolts or hangers prior to this revamp. The only hangers that they sold were the stainless climbing hangers or aluminum caving hangers. |

|

|

Will the PS bolt rust out at the same rate regardless of whether one uses a SS or PS hanger (given semi arid or even humid conditions)? |

Continue with onX Maps

Continue with onX Maps Continue with Facebook

Continue with Facebook