|

|

20 kN

·

Nov 17, 2016

·

Unknown Hometown

· Joined Feb 2009

· Points: 1,346

·

Nov 17, 2016

·

Unknown Hometown

· Joined Feb 2009

· Points: 1,346

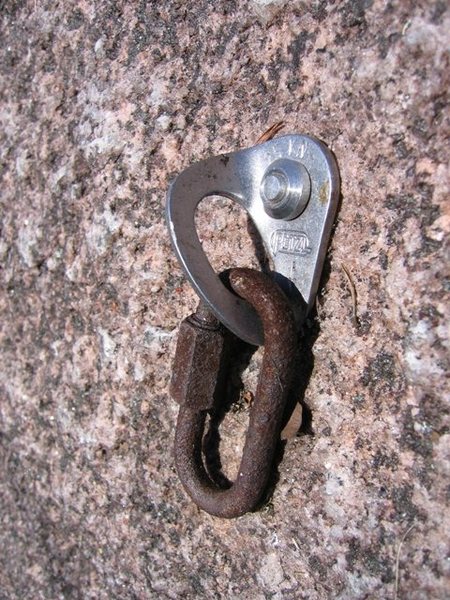

I pulled these anchors down and replaced them with titanium:

Believe it or not, those quicklinks are actually 304 stainless steel just like the bolts, hangers and ring. They were also placed in and removed from service at the same time as the other components. Despite being the same grade of stainless, the performance of the product is far inferior. The bolts, hangers and ring show limited corrosion where the quicklinks are completely corroded. As with any other product, stainless manufacturers have many ways to cut corners and make a crap product that is "technically" in line with their competitor's products, but realistically far inferior. This is not new news by many means, but possibly worth sharing in case someone dident know.

|

|

|

Jim Titt

·

Nov 17, 2016

·

Germany

· Joined Nov 2009

· Points: 490

It´s suprising how much stuff isn´t what it says. Years ago one of the yachting magazines did a test on a load of "marine" hardware with dissapointing results to put it nicely, we got ten different stainless karabiners tested once and only two were actually 316.

Both my suppliers (metal stock and hardware) do their own analysis but get down to hardware store stuff and it´s anyone´s guess what it is. We do our own destructive testing anyway to make sure since usually the "316" stamped stuff actually breaks at about 1/3rd of what it should take, we´ve also noticed that if you put it through passivating the appearance is different to usual so that could be a cheap and easy way to at least partly check for normal users.

Another thing to check, especially with quicklinks is see how the threaded part is made, better ones the end of the bar is forged out and the thread rolled in place, cheapo ones the threaded end is actually a sleeve either welded on or electro-plated on. These aren´t real strong!

|

|

|

John Byrnes

·

Nov 17, 2016

·

Fort Collins, CO

· Joined Dec 2007

· Points: 392

No kidding, those links have that characteristic look of stainless about to break

from SCC. And do I see cracks in the right one, just above the sleeve, in Yum2?

How long have they been on the wall?

Were the links bought through a climbing equipment supplier or some other source?

|

|

|

Jim Titt

·

Nov 17, 2016

·

Germany

· Joined Nov 2009

· Points: 490

John Byrnes wrote:No kidding, those links have that characteristic look of stainless about to break from SCC. And do I see cracks in the right one, just above the sleeve, in Yum2? How long have they been on the wall? Were the links bought through a climbing equipment supplier or some other source? Bullshit, you can´t normally even see SCC. They´ve got the usual exfoliation and crevice/pitting corrosion just like a bit of mild steel would get.

|

|

|

Stiles

·

Nov 17, 2016

·

the Mountains

· Joined May 2003

· Points: 845

Where is this crag located? Any why titanium replacements? I though titanium quality was even more unreliable than most everything else

|

|

|

Brian in SLC

·

Nov 17, 2016

·

Sandy, Utah

· Joined Oct 2003

· Points: 21,746

Yeah, no way those rapides were stainless.

Edit to add...have you tried a magnet on them?

|

|

|

John Byrnes

·

Nov 17, 2016

·

Fort Collins, CO

· Joined Dec 2007

· Points: 392

Jim Titt wrote: Bullshit, you can´t normally even see SCC. They´ve got the usual exfoliation and crevice/pitting corrosion just like a bit of mild steel would get. Jim, you are clearly a skeptic but I have personally seen nearly a thousand stainless bolts, both 304 and 316, affected by SCC. They are usually pitted and have that characteristic discoloration caused by rust after the microscopic SCC cracks have liberated the chromium from the steel. In addition, Prosek showed that pits are often starting points for SCC. So when stainless gets discolored like in 20kN's photo, and you know the environment they were in promotes SCC, it is almost a certainty they are being attacked by SCC. If you disagree, then identify some other corrosion mechanism that will make stainless steel look like that. 20kN has verified that they are stainless and not mild steel. I suspect they are not really 304, even though they were sold that way. And they look far worse than the link in the photo below, which has the "look", and has cracked through.

|

|

|

Brian in SLC

·

Nov 17, 2016

·

Sandy, Utah

· Joined Oct 2003

· Points: 21,746

20 kN wrote: They were stainless. I can say with absolute certainty. How so? Not asking to be a jerk, but, to learn.

|

|

|

Jim Titt

·

Nov 18, 2016

·

Germany

· Joined Nov 2009

· Points: 490

20 kN wrote: I have several samples that have visible cracks. Here is one. I took this photo with my phone. This was part of a lower-off anchor, so the shackle probably never saw more than a few hundred pounds. That is almost certainly crevice corrosion starting from the point where the flange on the pin started making contact with the body, you can see where the imprint from it stops exactly where the corrosion starts. Still cracked though!

|

Continue with onX Maps

Continue with onX Maps Continue with Facebook

Continue with Facebook