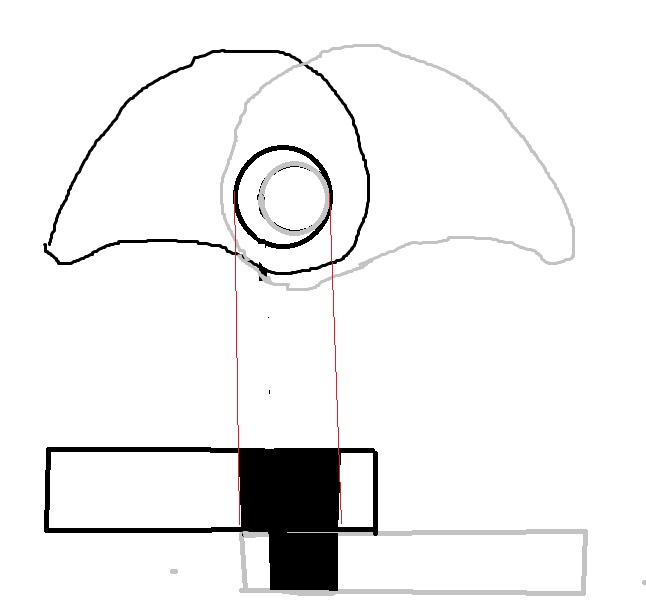

CAD model of a BD camalot number 1

|

|

DannyUncanny wrote:I've got access to a waterjet cutter. I could churn out crude looking cam lobes all day for the cost of material and about $1/min of nozzle wear. I'm thinking of maybe making some bigguns...What is the speed of the cutter on .25 inch aluminum? $1/min plus plate can add up. |

|

|

Something around 1" per second. Depends on a lot of factors |

|

|

Getting stock plate profile cut is cheap and easy, especially for those with basic CAD skills and industry contacts. |

|

|

Dylan B. wrote:I don't understand what the point of this isDo you trad climb? All the climbing gear you own was designed and tested by engineers, and Solid Works is an industry standard for 3D modeling. OP is likely an engineering student with an interest in trad climbing, and his post is a welcome contribution to the forums. |

|

|

MacM wrote:I'd be down for a #11 Hex Coffee cup as well! Also a "crude" #4 C4 Lobe to attach as a handle.i second that. except maybe a chouinard oval for a handle instead. would add the the vintage nature |

|

|

Tom Sherman, I've answered your CNC + _____ = Profit question. |

|

|

kennoyce wrote: The cam lobes still rotate around the center of their respective logarithmic spirals, just the hole drilled through the center of the inner lobes logarithmic spiral has a larger diameter to fit over the larger portion of the axle than the outer lobes axle hole. If this still doesn't make sense I can throw a model together at work on Monday, but alas, I don't have any CAD software on my home computer.Getting thru this thread after weekend. I fully understood, what I think, we are discussing, but, you can't take an object, spin it, and expect it to have two axis of rotation. I.e. in a solid axle, with an expanded section of the axle, scenario, there would have to be something more complicated going on. Otherwise you have one axis of rotation and the cam lobes respective origins would have to be same. |

|

|

The X4's have a stacked axle. Meaning on a single axle they have two axis of rotation. This is accomplished by an offset center for one set of lobes. |

|

|

On the technical stuff... where to start? |

|

|

No offense & not to be facetious, but all you guys declaring "X4 has stacked axle" Do you actually understand this? or are you just repeating it. I am very aware of what it looks like. Now point out to me, with a red dot, where the axis of rotation is. And describe to me, how that axis of rotation is at the origin point of both cam lobes. |

|

|

Look, made for ridiculousness. I can put an elephant in there. still doesn't change the fact that we're rotating around one axis. Now if you tell me the inner of the cam lobe is doing something else to complement this stacked axle. Then I'll believe you. And it will be too complicated for me to understand. |

|

|

Tom Sherman wrote:No offense & not to be facetious, but all you guys declaring "X4 has stacked axle" Do you actually understand this? or are you just repeating it. I am very aware of what it looks like. Now point out to me, with a red dot, where the axis of rotation is. And describe to me, how that axis of rotation is at the origin point of both cam lobes.Tom, just look at the photo posted by rocknice2 above. The axis of rotation for the grey lobe is the center of the large portion of the axle, and the center of rotation for the black lobe is the center of the small portion of the axle. Just put your own red dots at the center of the two portions of the axle and those two points are the equivalent of the two axles on a double axle cam. Everything else works just like a C4 except that they need to drill out the axle holes larger in those two cam lobes and they don't need to machine out a space for the other axle to pass through the lobes. |

|

|

kennoyce wrote: Tom, just look at the photo posted by rocknice2 above. The axis of rotation for the grey lobe is the center of the large portion of the axle, and the center of rotation for the black lobe is the center of the small portion of the axle. Just put your own red dots at the center of the two portions of the axle and those two points are the equivalent of the two axles on a double axle cam. Everything else works just like a C4 except that they need to drill out the axle holes larger in those two cam lobes and they don't need to machine out a space for the other axle to pass through the lobes.You CANNOT take a singular solid object and rotate it around two planar but separate axis of rotation - Physics |

|

|

As luck may have it I am also pretty good at making coffee mugs in particular the extruded kind. Wouldn't be the hardest thing ever to make a couple of extrusion dies for the hex and a cam lobe handle, not so sure I can do and anodized glaze though.... |

|

|

Tom Sherman wrote: You CANNOT take a singular solid object and rotate it around two planar but separate axis of rotation - PhysicsI'm really starting to think that you're just trolling now. Nobody ever said that a singular solid object is rotating around two planer but seperate axis of rotation. I'm saying that four individual and seperate objects (the cam lobes) are rotating about two separate axis of rotation. The two inner lobes rotate about the center of the wider portion of the axle and the two outer lobes rotate about the center of the thinner portions of the axle. |

|

|

You don't actually understand this do you? |

|

|

Tom Sherman wrote: You CANNOT take a singular solid object and rotate it around two planar but separate axis of rotation - PhysicsYou're not rotating the axle, you're rotating the lobes. The axle just provides two points of rotation, one for each set of lobes. The axle is actually fixed to the stem so it can't rotate. |

|

|

I'll now offer $5, to either one of you, who can explain this concept, clearly. Be it through drawings, video, a medium other than words. But the offer has an expiration of 2 hrs. from now. |

|

|

Tom Sherman wrote:You don't actually understand this do you? Steps to prove yourself wrong: 1. Take two things. (2 pens, or 1 pen and one marker, or 1 pen and one watermelon, or a watermelon and a grapefruit) 2. Tape them together, or insert them into each other, weld them, glue them, fart on em... 3. Rotate them. 4. With them solidly connected to each other, tell me that they are rotating about two different axis.THE AXLE DOESN'T ROTATE! There isn't a cam in existance that requires the axle to rotate and the X4 is no different. The axle is held stationary by the stem and the lobes rotate around the axle JUST LIKE EVERY OTHER CAM IN EXISTANCE. |

|

|

Tom Sherman wrote:I'll now offer $5, to either one of you, who can explain this concept, clearly. Be it through drawings, video, a medium other than words. But the offer has an expiration of 2 hrs. from now. I am also going to draw you a diagram, of the only way this could possibly work. (negating the idea that the inner of the cam lobe accounts for some sort of off-origin rotational shift) So I will draw you a non solid axle.I was hoping to be able to throw a quick modle together but unfortunately our NX licensing server is currently down so i can't access the software. |

Continue with onX Maps

Continue with onX Maps Continue with Facebook

Continue with Facebook